Flooring material heat radiation tester

A floor covering material and heat radiation technology, applied in the field of floor covering material heat radiation tester, can solve the problems of complex combustion behavior of flame retardant materials, combustion test methods cannot fully describe combustion performance, etc., and achieve high precision, low cost, resistance to The effect of combustion mechanism help

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

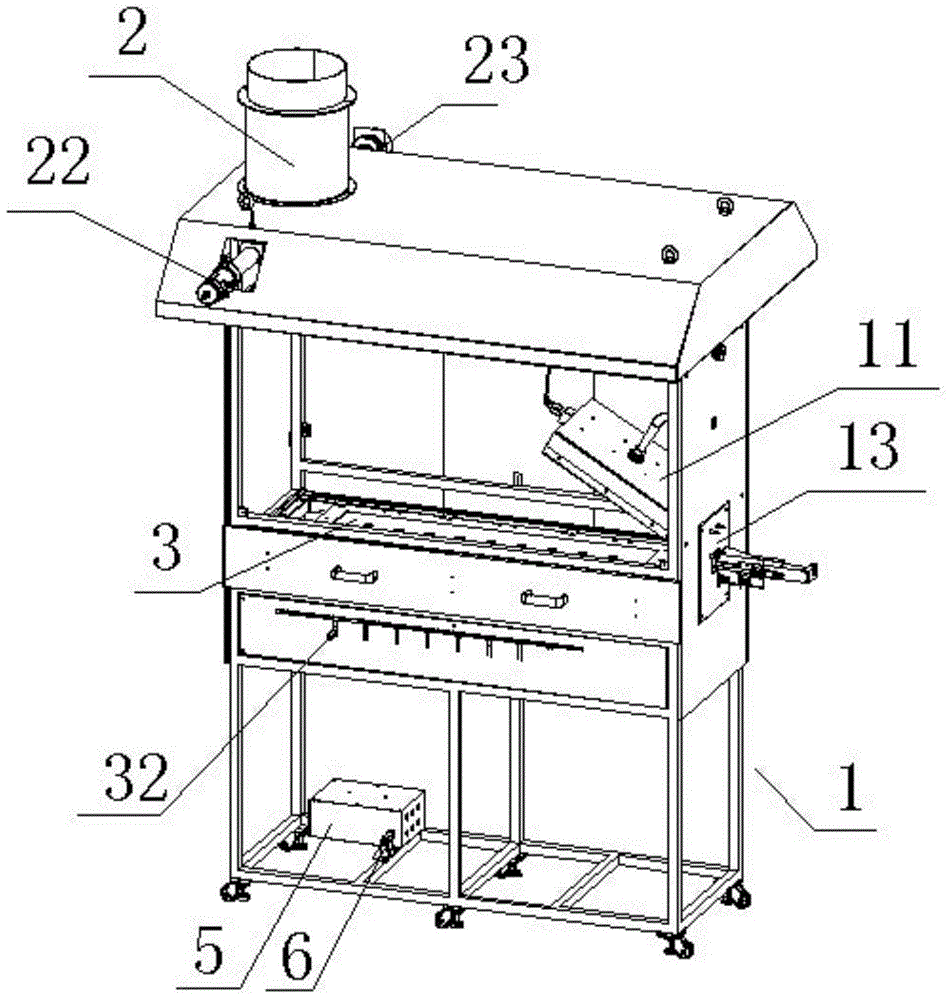

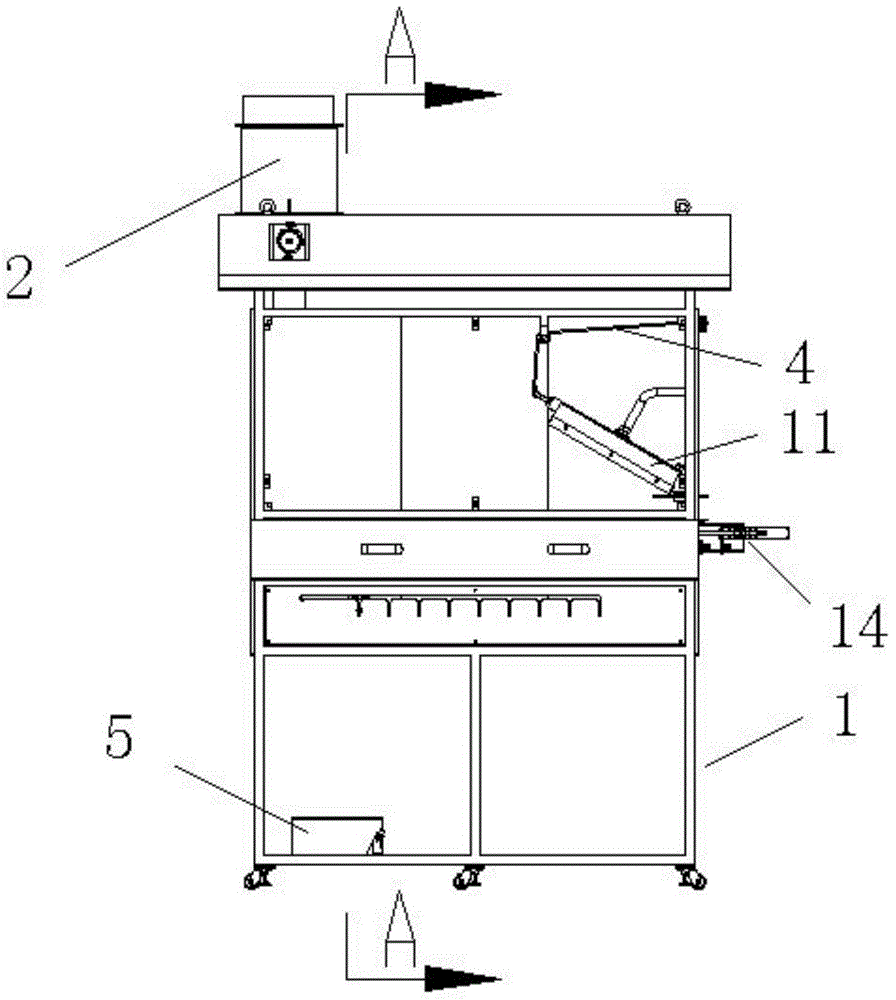

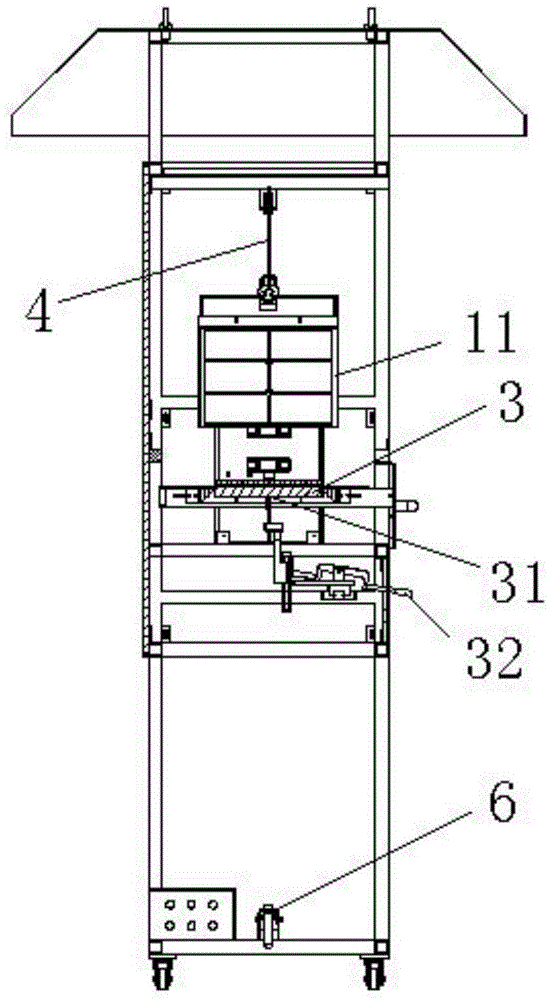

[0020] The present invention is described below in conjunction with accompanying drawing.

[0021] as attached Figure 1-5 As shown, a kind of thermal radiation tester for flooring materials according to the present invention includes a test frame 1, and a smoke exhaust fan 2, a heat source assembly, a workbench 3 and a heat flow meter assembly are arranged on the test frame 1; The smoke blower 2 is arranged on the top of the test frame 1, and the heat flow meter assembly is arranged on the lower side of the workbench 3; the heat source assembly includes a radiation heat source 11, a burner 12 and a connecting plate 13; the lower end of the radiation heat source 11 is hinged on On the test frame 1, the radiant heat source 11 is suspended by a sling 4, and the other end of the sling 4 is connected to a knob, and the sling 4 is adjusted by adjusting the knob, thereby adjusting the inclination angle of the radiant heat source 11; the burner 12 It is a T-shaped burner; the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com