Weed control method of mechanical hill-drop drilling paddy field

A technology for direct seeding in a hole and a paddy field is applied in the field of weed control in mechanically direct seeding in a rice field, which can solve the problems of large gap between rows, increasing the competitiveness of weeds, and poor sealing effect of weeds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

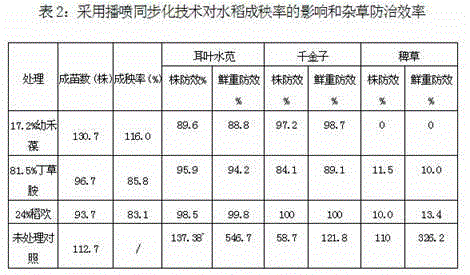

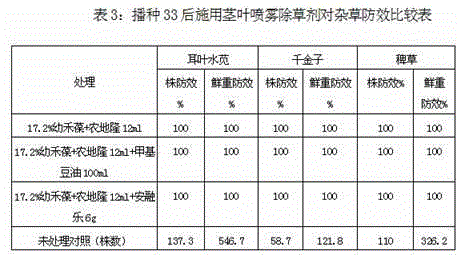

Embodiment 1

[0019] The rice variety used in the experiment was the conventional rice Kejia 58, which was sown on June 15. The seeds are pre-sterilized, soaked and germinated.

[0020] The natural weeds in the experimental field include annual grass weeds A. chinensis and barnyardgrass, and annual broad-leaved weeds such as amaranthus and oyster.

[0021] The experimental site is located in Huaxing Farm, Wuyuan Town, Haiyan County, Zhejiang Province. The previous crop of this experiment is winter wheat. Fertilize as usual.

[0022] Herbicides used in the test: 24% Daohuan (Dow AgroSciences), 81.5% Butachlor (Shandong Qiaochang Chemical Co., Ltd.), 17.2% Youhebao (Zhejiang Leji Chemical Co., Ltd.), Anrongle (Dow AgroSciences, USA) and methyl soybean oil (provided by Dow AgroSciences, USA);

[0023] The area of the test field is 99 mu, and the area of the plot is 422m 2 , repeated 3 times, arranged in random blocks. The soil in the test field is Qingzi mud, with a pH value of 6.5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com