Ceiling keel structure and mounting method

An installation method and keel technology, applied to building components, building structures, construction, etc., can solve problems such as high labor intensity, time-consuming, difficult adjustment and disassembly, etc., to improve work efficiency, ensure safety, and save workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

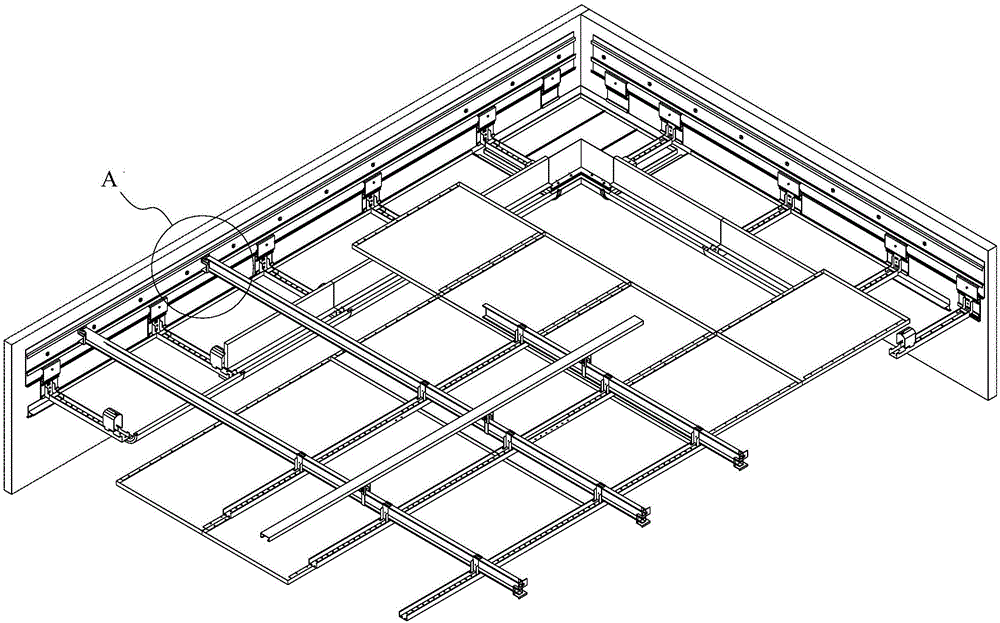

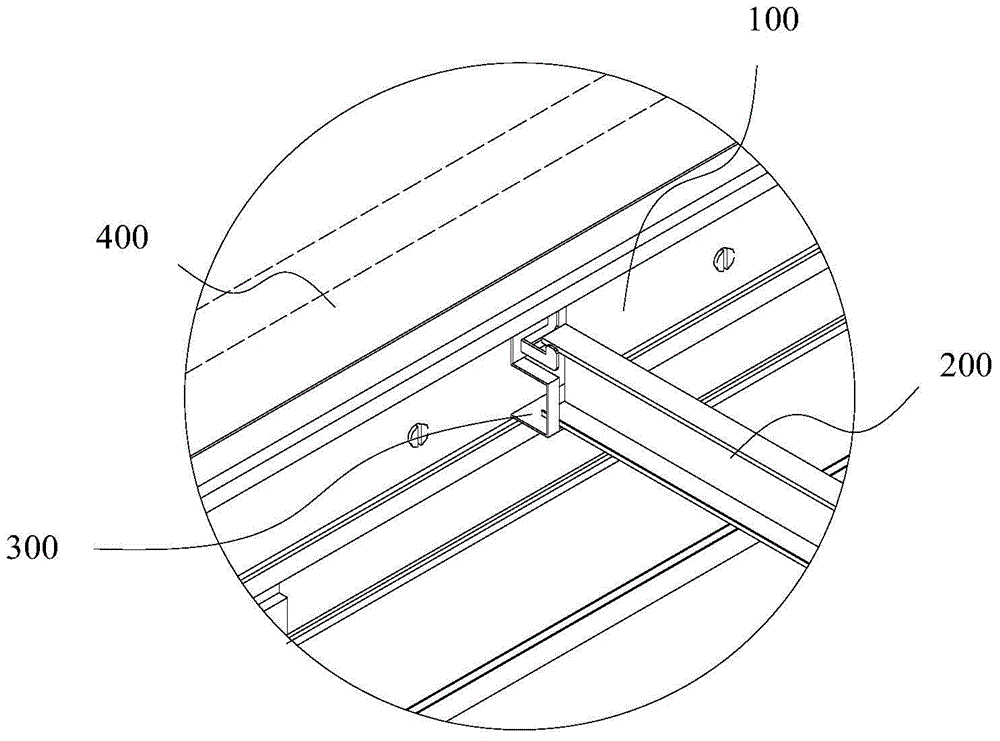

[0036] The ceiling keel 200 structure includes: a keel 200 , at least two supporting beams 100 , and a connecting piece 300 .

[0037] Wherein, at least two wall surfaces 400 are arranged opposite to each other, and at least two support beams 100 are fixed to the wall surfaces 400, which can be nailed with expansion nails or directly embedded in the wall body.

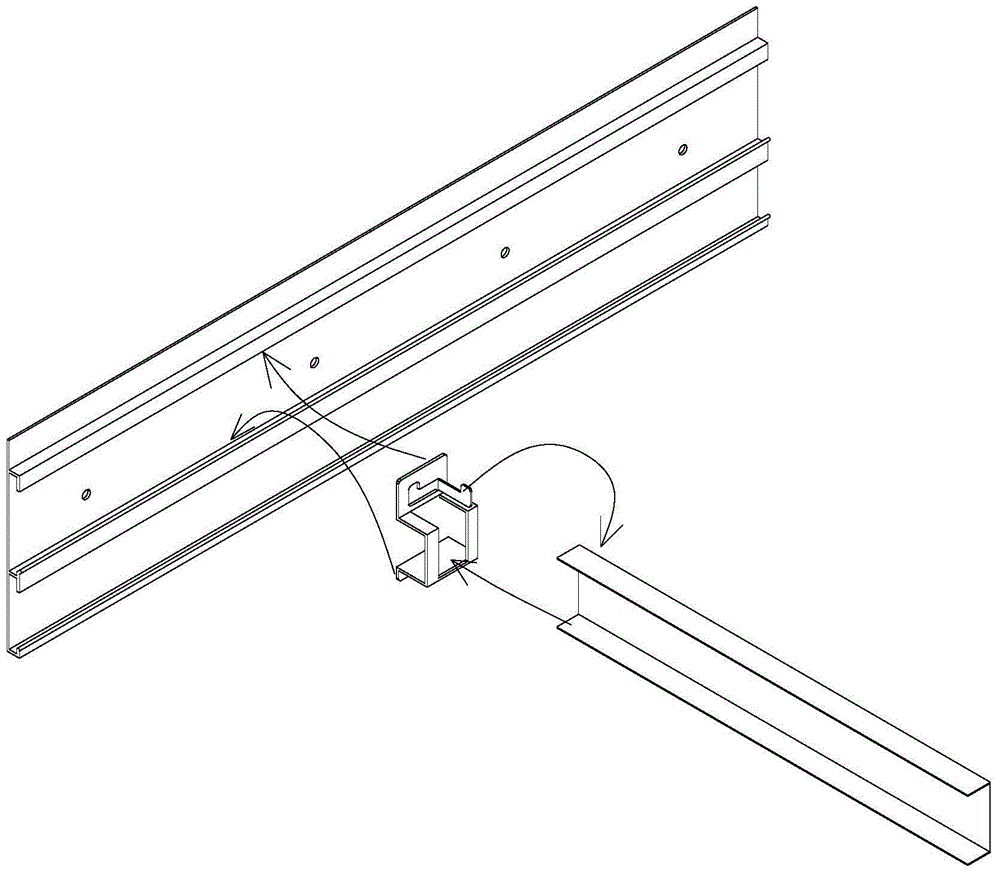

[0038] The two ends of the keel 200 respectively correspond to a support beam 100, the support beam 100 is provided with a transverse slideway, the transverse slideway includes an upper slide rail 110 and a lower slide rail 120 arranged up and down, and the edge of the upper slide rail 110 is bent to form a first hook, The edge of the lower rail 120 is bent to form a second hook.

[0039] The connecting part 300 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com