On-site inspection device and method for dissolved gas in transformer oil on-line monitor

A technology for dissolving gas and transformer oil, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of high detection accuracy, simple structure and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

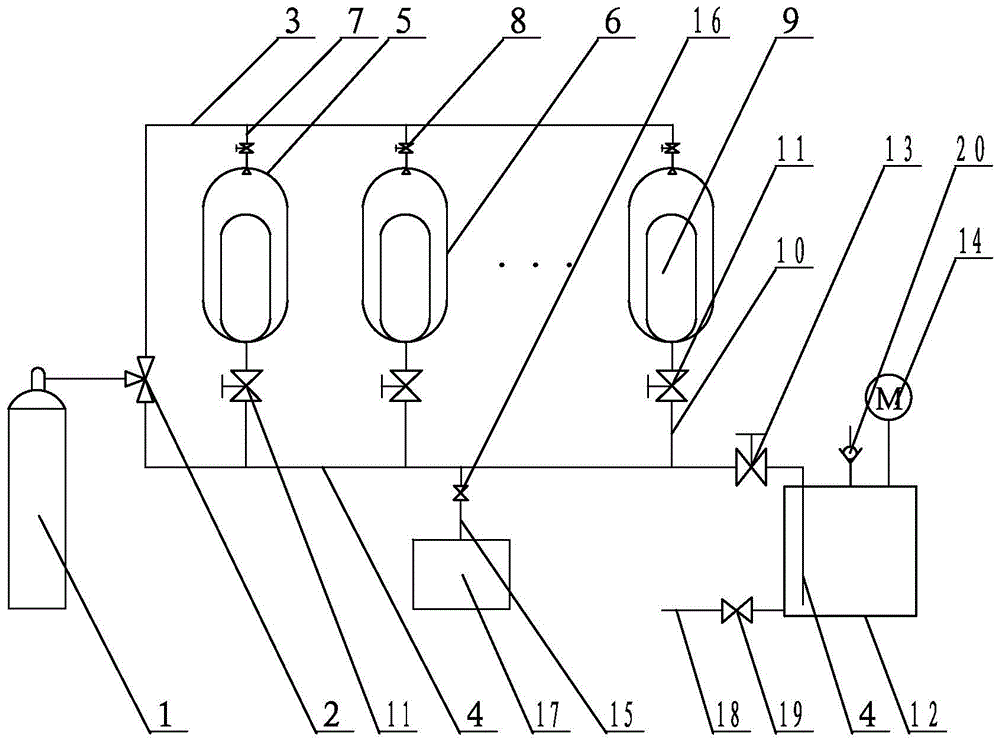

[0025] Such as figure 1 As shown, the on-site inspection device of the dissolved gas online monitor in transformer oil of the present invention includes a gas cylinder 1, an oil sample tank and an oil collection tank 12, the gas cylinder 1 is provided with an outlet, and the gas cylinder 1 outlet is connected to three The one-way valve 2 and the three-way valve 2 are respectively connected to the oil sample tank and the oil collection tank 12 through the air delivery pipe 3 and the oil delivery pipe 4. The oil sample tank includes a plurality of test oil sample tanks 6 and a new oil sample tank 5, and the air delivery pipe 3 Corresponding to each oil sample tank on the top, an air intake branch pipe 7 is respectively arranged, an air intake valve 8 is arranged on the air intake branch pipe 7, an elastic oil-resistant air bag 9 is arranged inside the oil sample tank, and the oil sample is contained in the elastic oil-resistant air bag 9, and the bottom outlet of the elastic oil-...

Embodiment 2

[0029] This embodiment provides a method for inspection using the on-site inspection device of the online monitor for dissolved gas in transformer oil described in Embodiment 1, including the following steps:

[0030] The first step is to open the gas cylinder 1, switch the three-way valve 2 to connect the oil delivery pipe 4, open the collection valve 13, and the pressure gas in the gas cylinder 1 will blow the residual impurities in the oil delivery pipe 4 to the oil collection tank 12;

[0031] In the second step, switch the three-way valve 2, communicate with the gas supply pipe 3, open the vacuum device 14, and vacuumize the oil supply pipe 4;

[0032] The third step is to close the collection valve 13, open the inlet valve 8 and the oil sample valve 11 at both ends of one of the test oil sample tanks 6 according to the detection requirements of the device 17 to be detected, and open the detection valve 16 at the same time, and the gas in the gas cylinder 1 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com