Rotation elevating apparatus of overhead ground wire of power transmission line

An overhead ground wire, rotary lifting technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of secondary personnel injury, personnel dangerous action and personnel injury, so as to optimize the operation mode, simplify the operation process, improve efficiency and safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

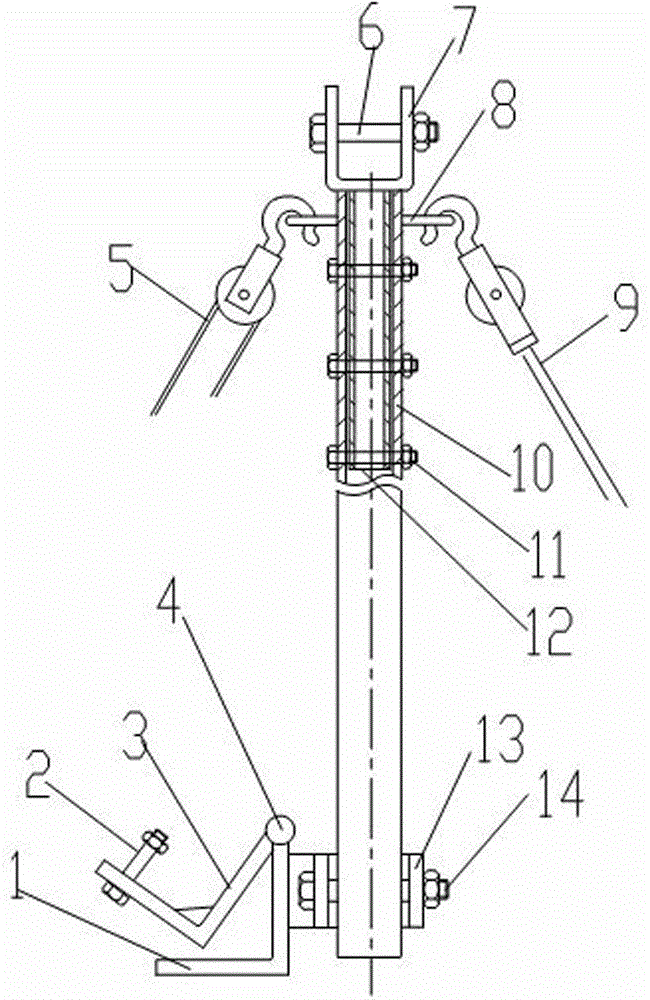

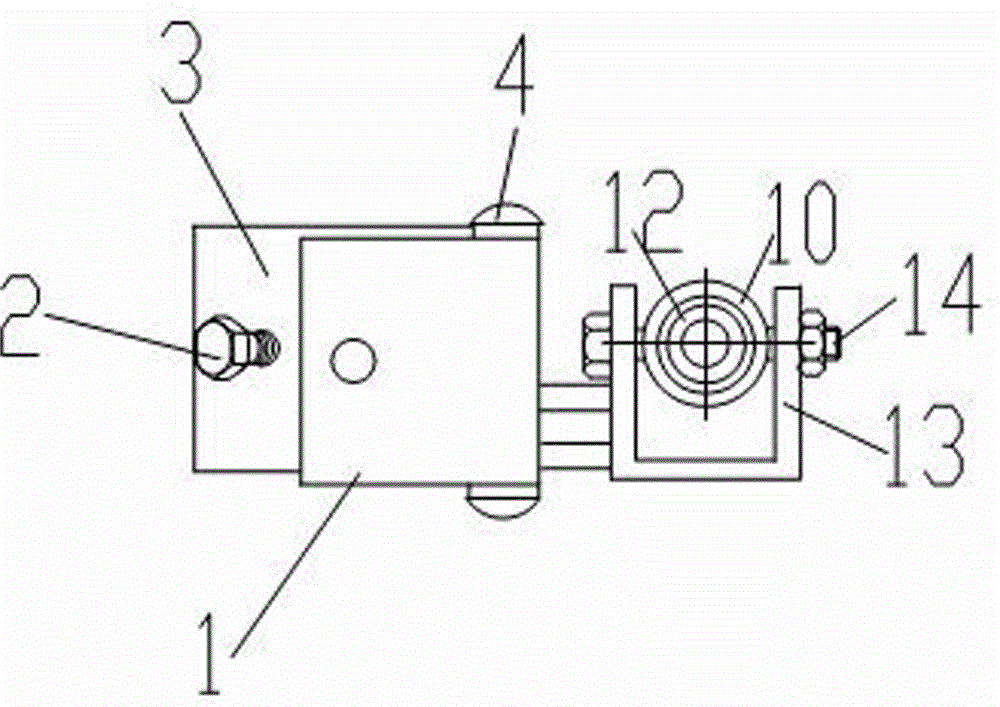

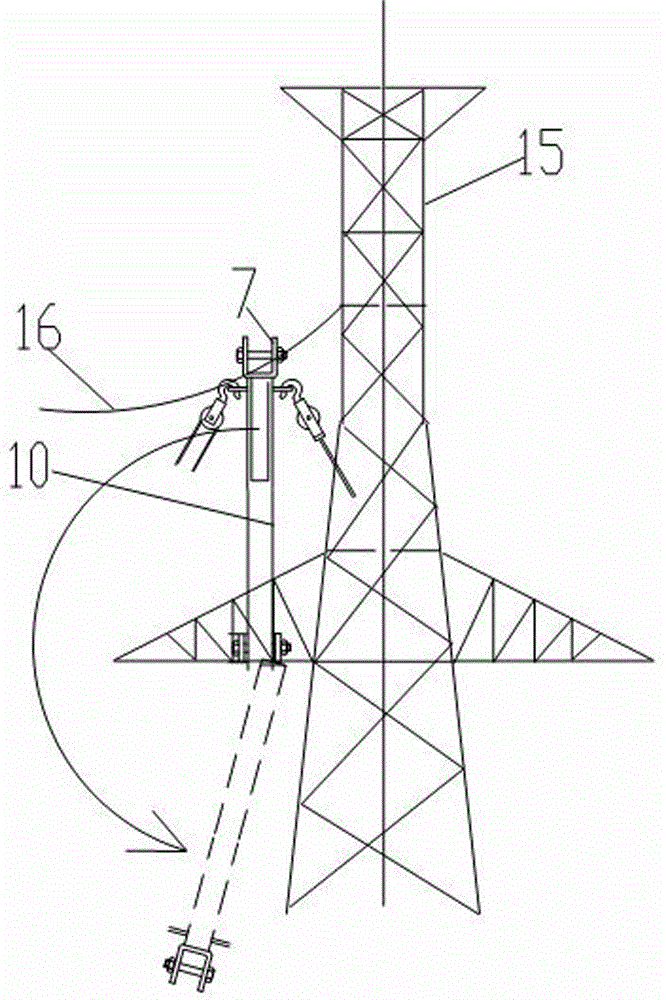

[0011] (See Figure 1-3 ) A rotary lifting device for overhead ground wires of power transmission lines, including a main body standpipe 10, the upper end of the main body standpipe 10 is provided with a shackle shackle, and left steel shackles are respectively provided on the left and right sides of the shackle shackle. The stay cable 5 and the right side steel stay cable 9 are hinged at the lower end of the main body riser 10 with the seat body, and the seat body is provided with a clamping mechanism that can be fixed with the transmission tower rod 15 . The sleeve shackle is a U-shaped collar 7, and the U-shaped collar 7 is provided with a crossing bolt 6. It also includes a cable ring 8 symmetrically connected under the U-shaped collar 7 , the left steel cable 5 and the right steel cable 9 are respectively provided with hooks, and the hooks are connected to the cable ring 8 . The seat body is a U-shaped swivel seat 13 , and the lower end of the main body riser 10 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com