Stator for motor and method for manufacturing same

A motor and stator technology, applied in the field of improvement of motor stators, can solve problems such as bending of connecting wires, lengthening of motor axial direction, decrease in circularity of annular shape, etc., achieving high reliability, shortening distance, and preventing short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

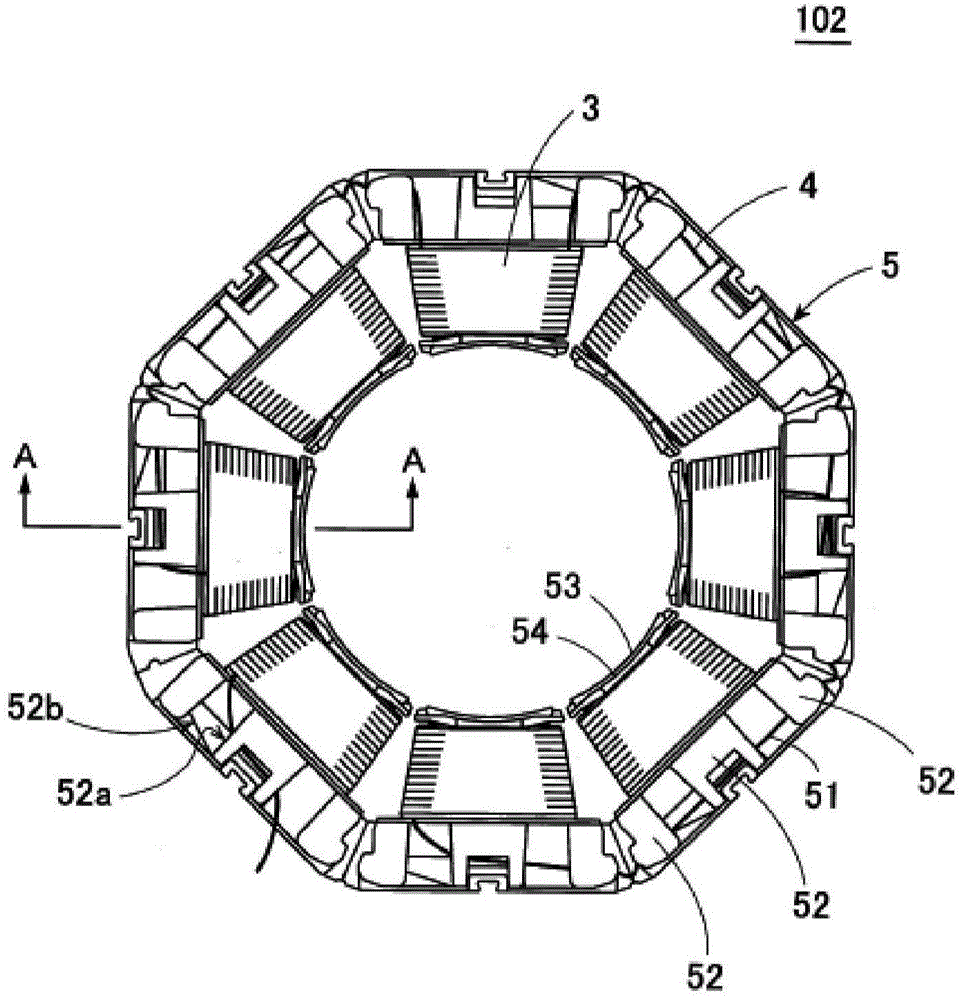

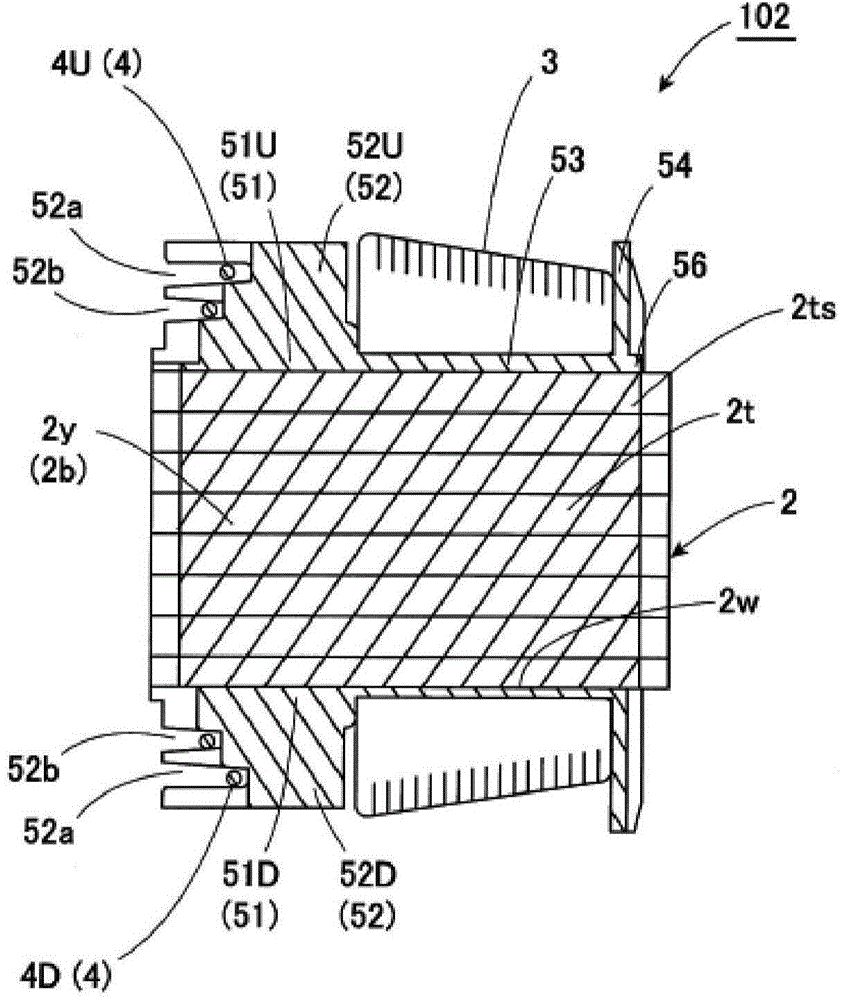

[0053] One embodiment illustrated in the present application will be described below with reference to the drawings. In this specification, the direction of the central axis J of the motor is described as the up-down direction for convenience, but it does not limit the posture of the motor involved in the present invention during use, and the direction of the central axis J of the motor is simply referred to as " "Axial" refers to the radial direction and the circumferential direction centered on the central axis J as "radial" and "circumferential" for short. The same applies to the stator and the stator core, and the directions that coincide with the axial, radial, and circumferential directions of the motor when they are assembled in the motor are referred to as "axial", "radial", and "circumferential" .

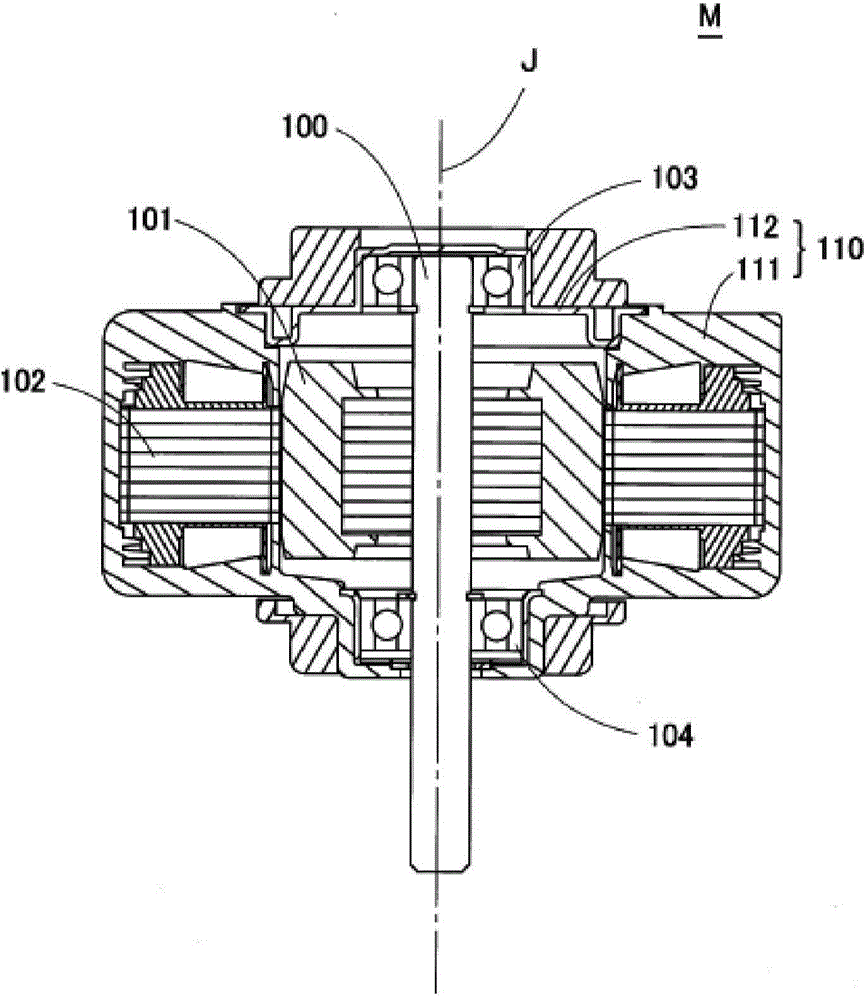

[0054] figure 1 It is a cross-sectional view of a motor M having an annular stator 102 according to an exemplary embodiment of the present application, and shows a cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com