Aeration device, operation method therefor, and water treatment apparatus

An operation method and technology of gas device, which are applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of membrane module function decline, gas turbulence for dispersing gas, expensive operation cost and equipment cost and other problems, to achieve the effect of high convenience and uniform air dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

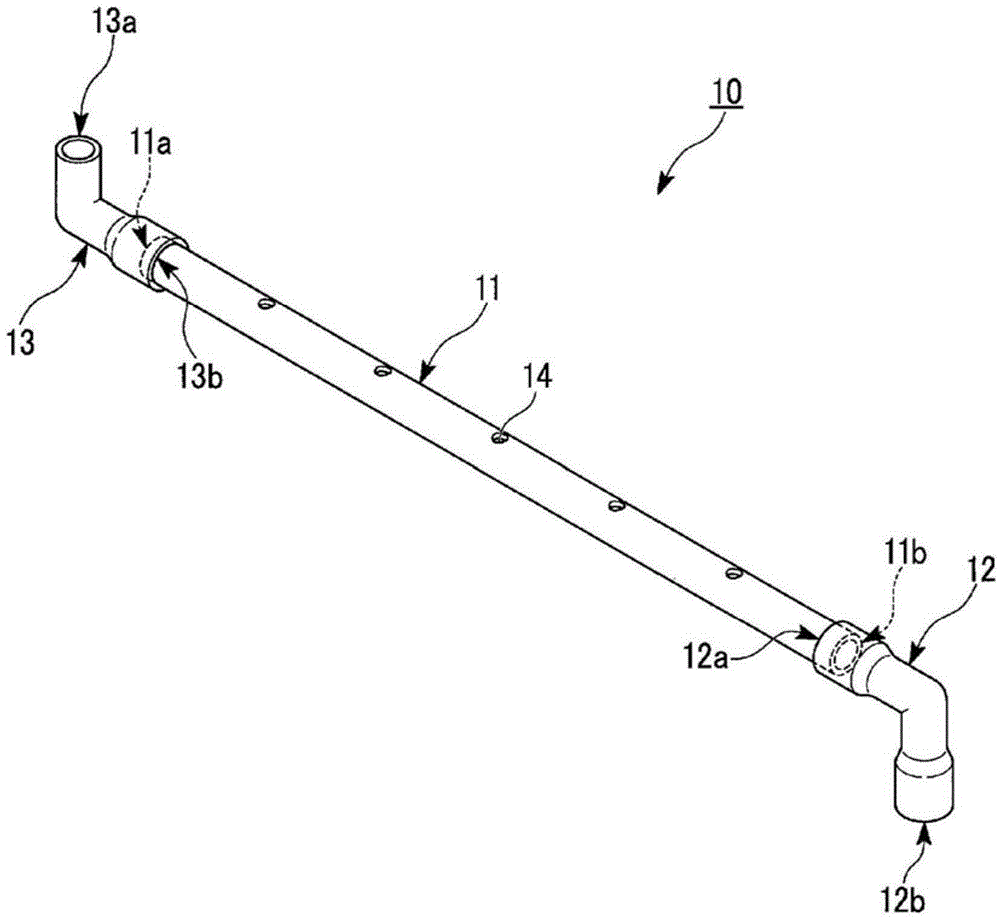

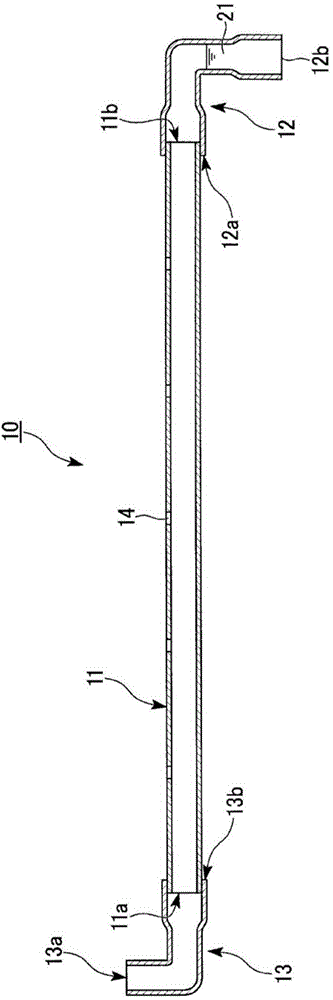

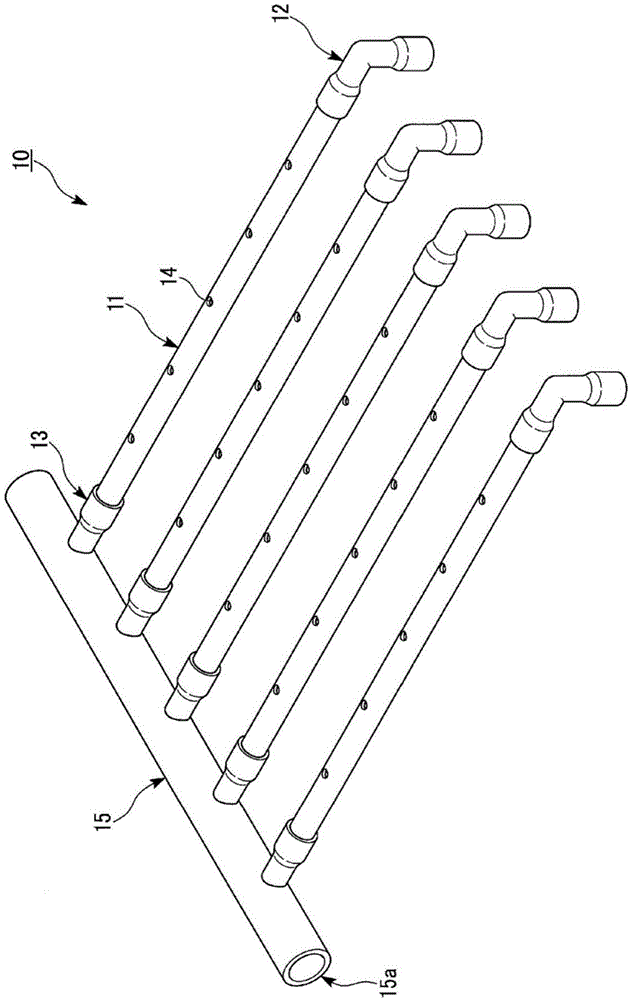

[0209] As the diffuser tube, a diffuser tube extending horizontally with an inner diameter D of 20.0 mm, a length L of 500 mm, and five circular diffuser holes with a diameter d of 6.0 mm at equal intervals was formed on the upper part.

[0210] The base end of the diffuser pipe communicates with the other end of the connecting member. In addition, the other end is opened to the vertically lower side, and one end of the open pipe extending from the other end side to the longitudinally lower side is directly communicated with the end of the diffuser pipe, forming a figure 1 The diffuser 10 shown. As an open pipe, a 90° elbow is used.

[0211] The gas supply pipe of the gas supply device was connected to one end of the connection member, and air was supplied from the gas supply device to the diffuser pipe of the diffuser device at an air volume of 100 l / min.

[0212] The flow velocity of the air flowing in the diffuser pipe is 5.3m / s. In addition, the air volume of the air b...

Embodiment 2

[0219] The air-diffusing properties were evaluated in the same manner as in Example 1 except that the inner diameter D of the air-diffusing tube was changed to 13.0 mm. Table 1 and Table 2 show the results.

[0220] In addition, the flow velocity of the air flowing in the diffuser pipe is 12.6 mm. In addition, the air volume of the air blown out from each diffuser hole was 20.0 l / min per diffuser hole. In addition, the flow velocity of the air emitted from each diffuser hole is 10.6m / s, 10.7m / s, 11.6m / s, 12.4m / s, 13.7m / s in order from the base end side of the diffuser pipe, and their average velocity It is 11.8m / s. In addition, the flow velocity of the air released from each air-diffusing hole is such that the cross-sectional area of the air-diffusing hole is formed to be 2.83×10 -5 m 2 come to ask for it.

Embodiment 3

[0222] The inner diameter D of the diffuser pipe was changed to 13.0 mm, and the air flow rate of the air supplied from the gas supply device to the diffuser pipe of the diffuser was changed to 75 l / min. Other than that, the diffused air was evaluated in the same manner as in Example 1. sex. Table 1 and Table 2 show the results.

[0223] In addition, the flow velocity of the air flowing in the diffuser pipe was 9.4 m / s. In addition, the air volume of the air blown out from each diffuser hole was 15.0 l / min per one diffuser hole. In addition, the flow velocity of the air diffused from each diffuser hole is 8.4m / s, 8.2m / s, 8.6m / s, 9.3m / s, 9.8m / s from the base end side of the diffuser tube, and their average velocity It is 8.9m / s. In addition, the flow velocity of the air released from each air-diffusing hole is such that the cross-sectional area of the air-diffusing hole is formed to be 2.83×10 -5 m 2 come to ask for it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com