Epitrochoid trajectory based fruit vibration harvesting device

An epitrochoid and trajectory technology, applied in the field of fruit vibration harvesting devices, can solve the problems of high requirements for use occasions, simple vibration trajectory, and unfavorable promotion and use, and achieve the goal of improving harvesting efficiency and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

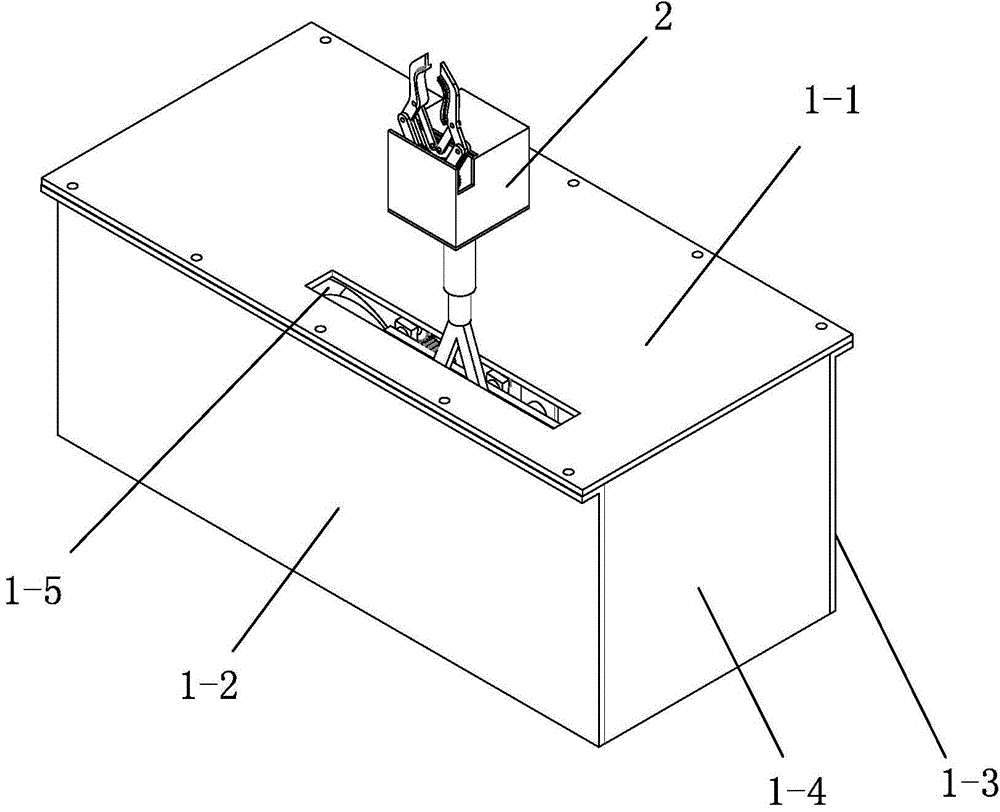

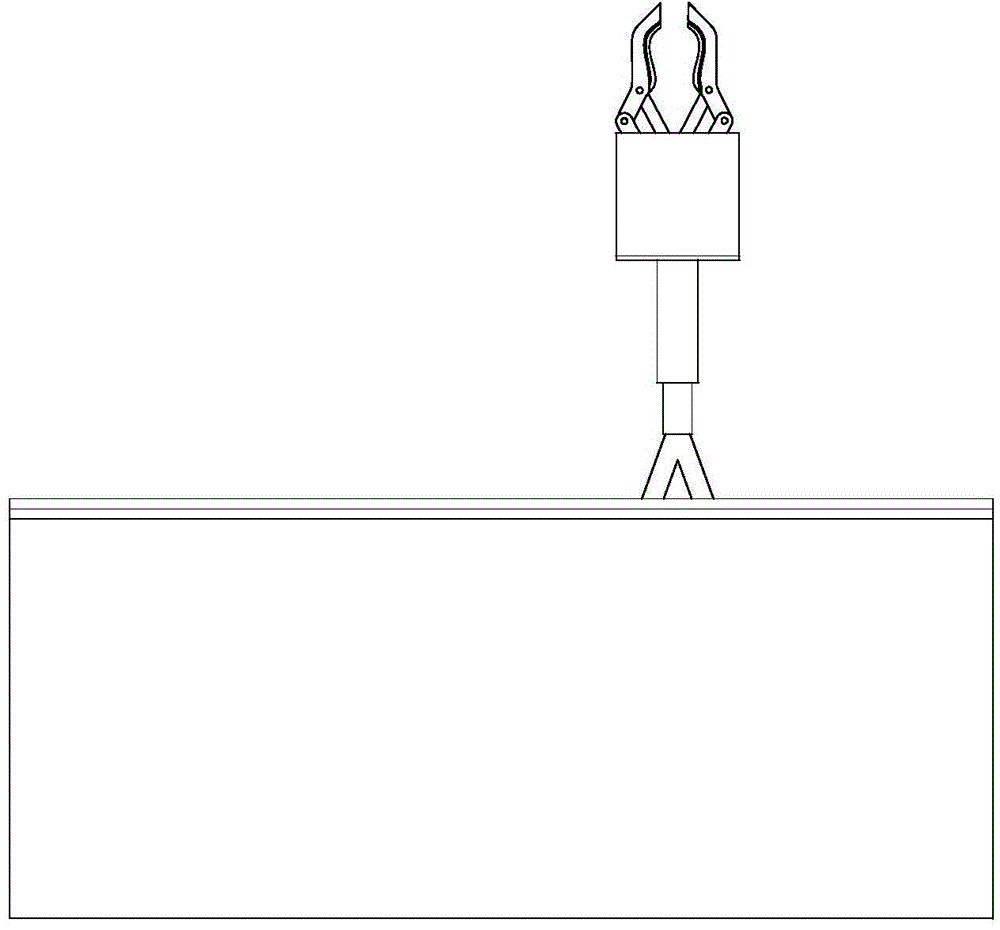

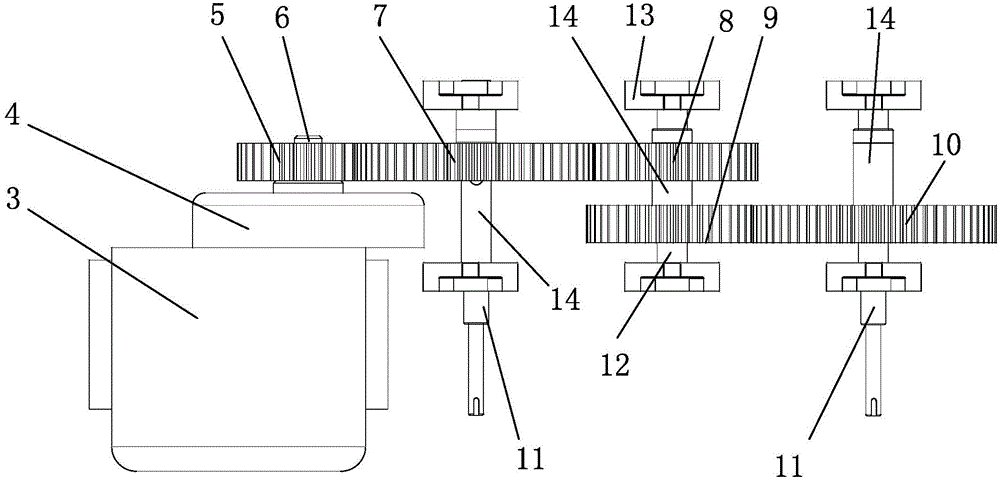

[0027] like Picture 1-1 , Figure 1-2 as well as Figure 7-1 , 7-2 As shown, the fruit vibration harvesting device based on the epitrochoid track of the present invention is usually installed on the vehicle-mounted platform, and the harvesting device includes a box body, a gripper unit, a shaking unit installed in the box body, and a transmission unit , Power unit. The power unit is connected with the vibration unit through the transmission unit, and drives the vibration unit to work; the vibration unit is connected with the gripper unit, and drives the gripper unit to move on an epitrochoid track.

[0028] like Picture 1-1 , Figure 1-2 , Image 6 As shown, the box body includes a base plate 1-7, a cover plate 1-1, two side plates 1-4, a front plate 1-2, a rear plate 1-3 and a movable plate 1-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com