Novel splicing assembly

A component and a new type of technology, applied in detachable cabinets, household appliances, applications, etc., can solve the problems of inconvenient use, weak structure, inability to splice into a three-dimensional sense of space, etc., and achieve the effect of reasonable parameter setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

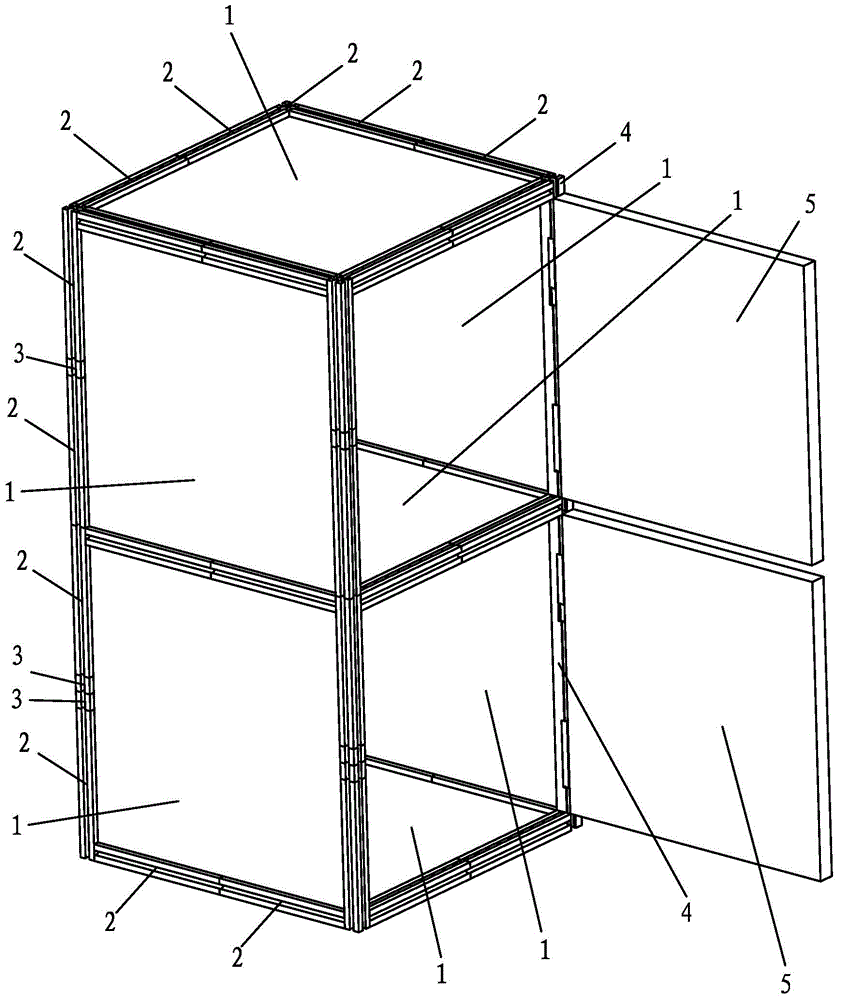

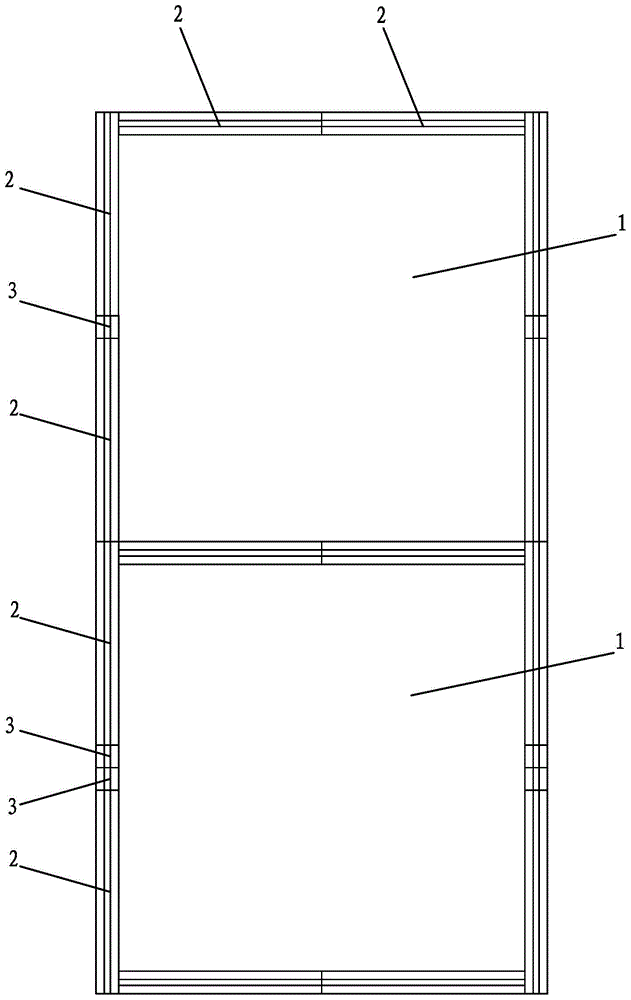

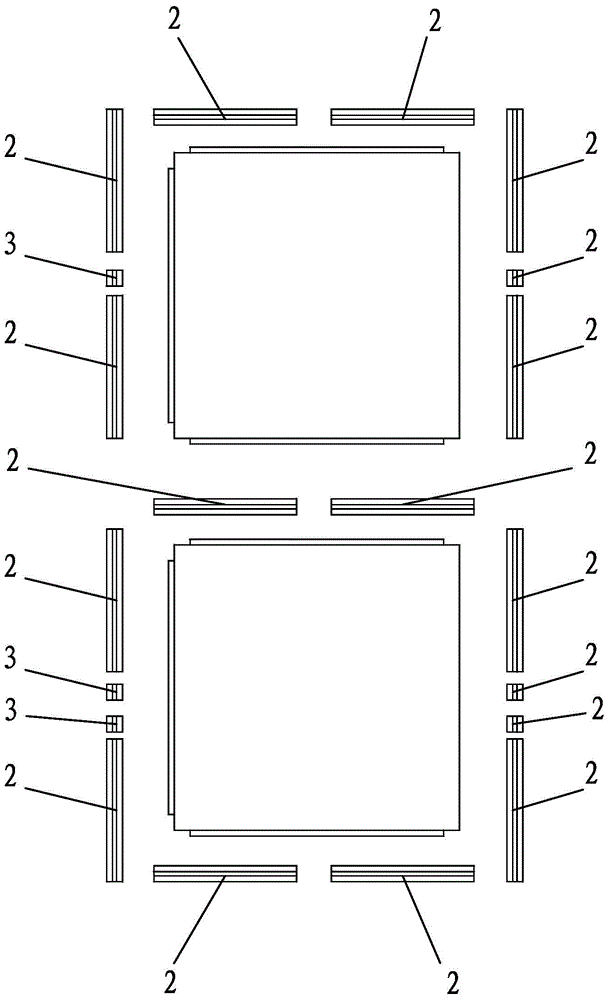

[0027] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

[0028] Such as Figure 1-14 As shown, a new type of splicing assembly includes a number of first square panels 1, a number of first bar-shaped connectors 2, and a number of second bar-shaped connectors 3, and the square side of the first square panel 1 The length is L and the thickness is D, wherein L>D, the length of the first strip connector 2 And the cross-section is a square with side length D, the length L2=D of the second strip connector 3 and the cross-section is a square with side length D, and there are 3 of the 4 side walls of the first square panel 1 The centers of the side walls are respectively provided with first clamping columns 11 parallel to the long side direction of the side walls, the length of the first clamping columns 11 is not greater than L, and the centers of the four side walls of the first strip connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com