Bag cage of bag type dust collector

A technology of bag filter and bag cage, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of filter bag wear, single function, unfavorable production efficiency, etc., so as to improve service life and reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

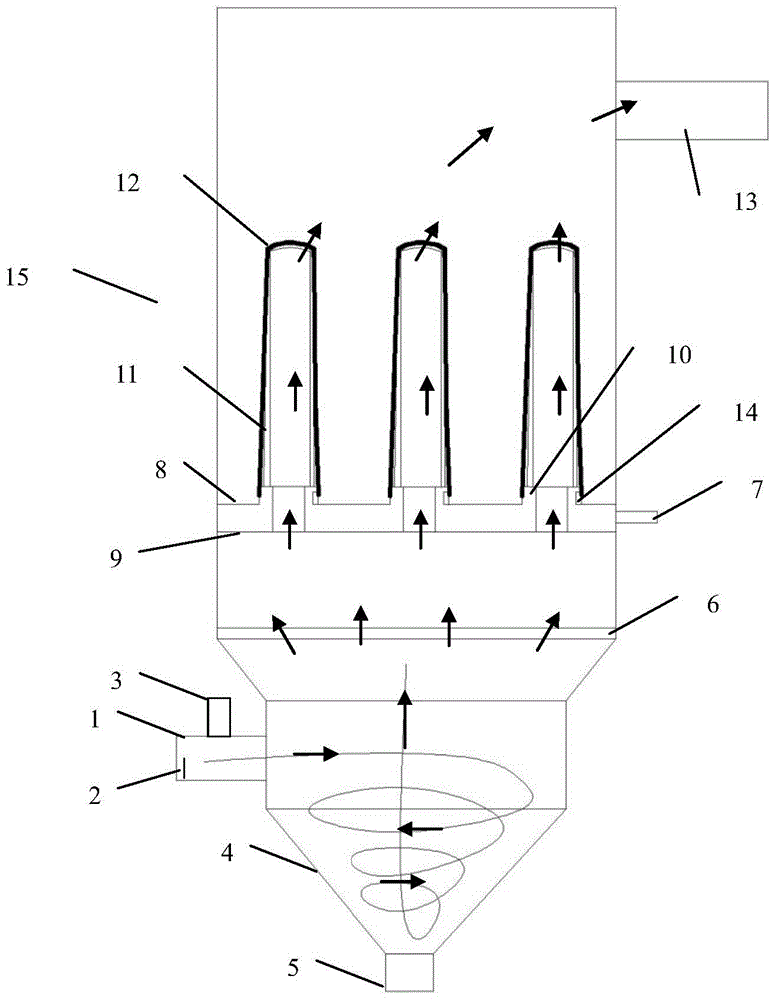

[0018] Such as figure 1 As shown, the dust-laden gas enters from the dust collector inlet 1. After passing through the inlet, the horizontally flowing gas becomes a rotating gas in the cone 4, and it will rotate around the side wall of the dust collector and move downward. Under the action of centrifugal force, the gas The large particles in the gas will be separated and fall into the ash hopper 5; the setting of the cone can effectively reduce the abrasive impact of the particles in the gas on the air tube 11 and the filter bag 12. The particles that cannot be separated will continue to move with the gas, and the gas will continue to move to the center and the lower end of the cone 4 at the same time, and when the gas reaches the lower end of the cone 4, it will turn and move upward to become an internal spiral gas. The inner swirling gas rotates upwards from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com