Automatic control-based high-speed sorting method

An automatic sorting and high-speed technology, applied in sorting and other directions, can solve the problems of slow sorting speed, achieve the effect of improving utilization rate and saving sorting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

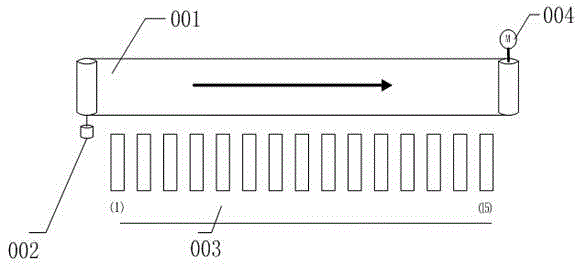

[0022] Attached to this example figure 2 Numbers (1)-(15) represent a total of 15 groups of automatic sorting mechanisms 003.

[0023] In this embodiment, the components of the conventional known structures are not described and shown in the figure.

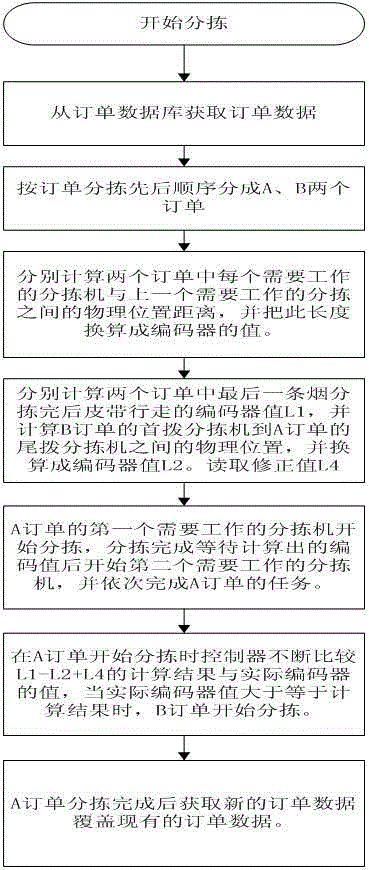

[0024] Such as figure 1 As shown, the high-speed sorting method based on automatic control disclosed in this embodiment, the high-speed sorting method based on automatic control, the method includes the following steps:

[0025] (1) Set up a transmission device, and arrange multiple sets of automatic sorting mechanisms 003 on one side of the transmission belt. The automatic sorting mechanism 003 includes a controller, and the transmission device includes a transmission belt 001. Set up a transmission device, and Multiple groups of automatic sorting mechanisms are arranged on one side of the transmission belt, the automatic sorting mechanism includes a controller, the transmission device includes a transmission belt, and the tr...

Embodiment 2

[0032] Such as figure 1 and figure 2 Shown: The running position of the transmission belt 001 is set to be measured by the encoder 002 installed on the belt. During automatic sorting, the transmission belt 001 runs at a constant speed. It is assumed that the sorting starts from the first cigarette of the current order to the last cigarette. After the tobacco sorting is completed, the length of the transmission belt 001 is L1, and the distance from the first cigarette bin in the next order to the last cigarette bin in the current order is L2. When the transmission belt 001 travels a length of L3, the next order starts to be sorted, corrected The value is L4. Then when L3>=L1-L2+L4, the first cigarette of the next order will not overlap the cigarette of the current order. If the correction value L4 is adjusted, the distance between the cigarettes of two adjacent orders can be adjusted.

[0033] The working principle is as follows: Assume that the current order is A, and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com