Assembly method of phaser lock pin clearance

A phase shifter and gap technology, applied in the field of phase shifter lock pin gap assembly, can solve problems such as abnormal noise at engine cold start, and achieve the effects of reducing processing difficulty, improving assembly production efficiency, and optimizing processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

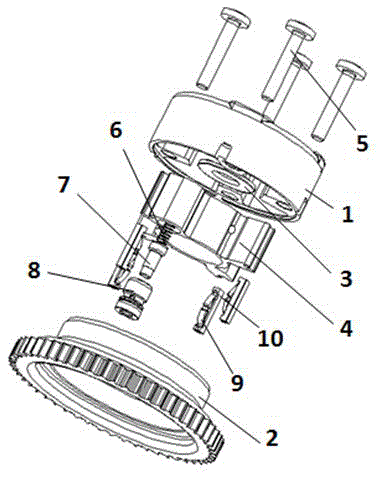

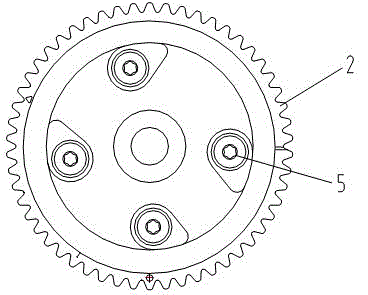

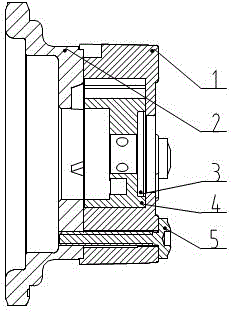

[0013] Such as figure 1 , 2 , 3, 4, and 5, the phase shifter includes a stator 1, a gasket 3, a rotor 4, a lock pin 7, a lock pin sleeve 8, a lock pin spring 6, an oil seal 10, an oil seal spring 9, a sprocket 2 and bolts 5. The phase shifter lock pin gap assembly method, ① The rotor 4, the lock pin 7, the lock pin sleeve 8, the lock pin spring 6, the stator 1, the oil seal 10 and the oil seal spring 9 constitute the stator-rotor assembly, and then the stator-rotor assembly and the sprocket 2 combined and rotated with each other so that the lock pin 7 on the rotor 4 snaps into the lock pin hole on the sprocket 2, and then the bolt 5 is locked into the sprocket 2 with an electric screwdriver so that the stator-rotor assembly and the sprocket 2 will not fall off each other. At this time, the stator-rotor assembly and the sprocket 2 can still rotate with each other; ②Use to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com