Multifunctional bilateral edge-grinding device for knife bending machine, knife bending machine and edge-grinding method

A machete machine and multi-functional technology, applied in the direction of grinding drive device, grinding machine, grinding workpiece support, etc., can solve the problems of time-consuming, labor-intensive, efficiency discount, etc., to improve processing efficiency, reduce space occupation, improve grinding and cutting efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

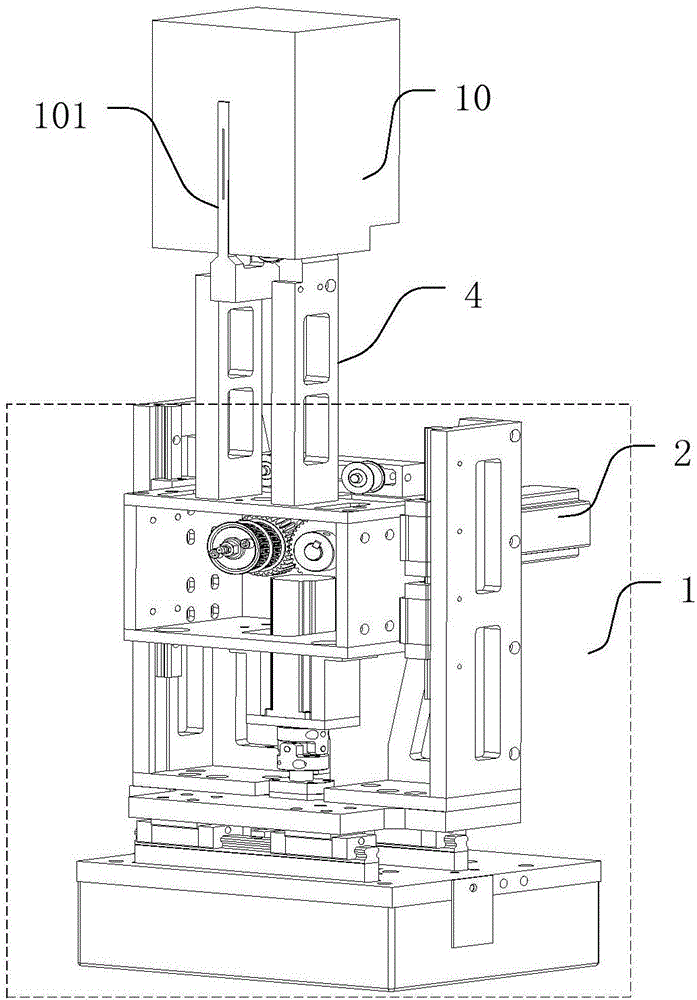

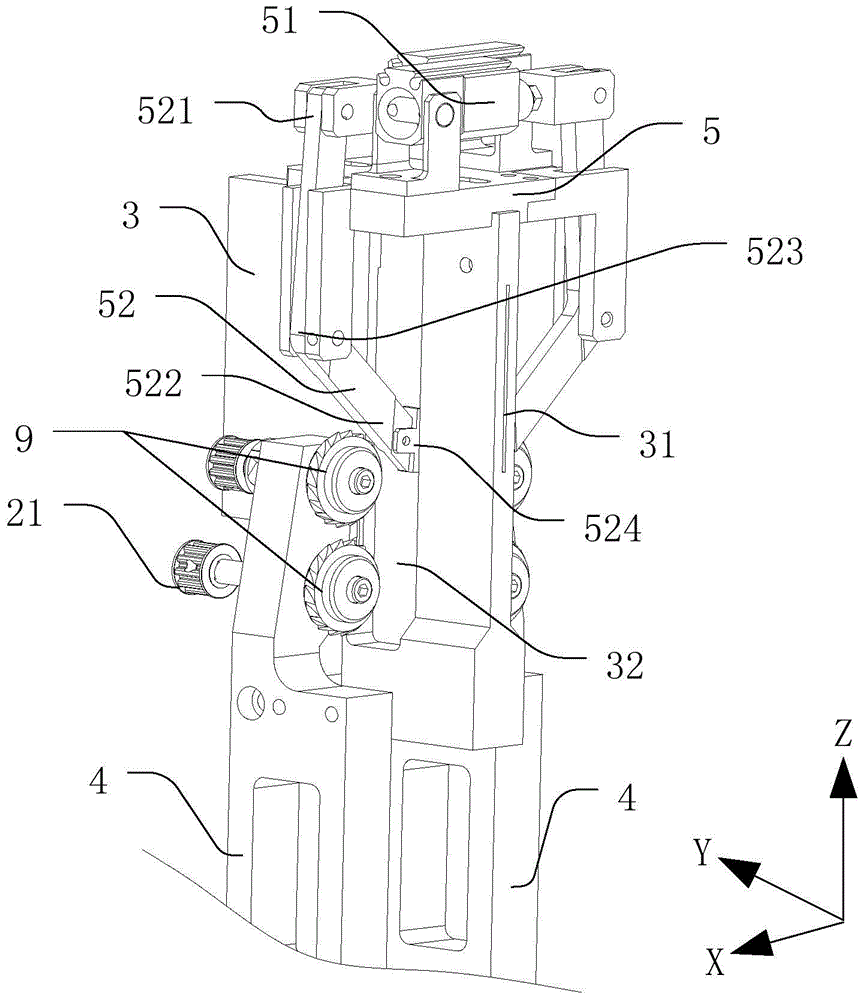

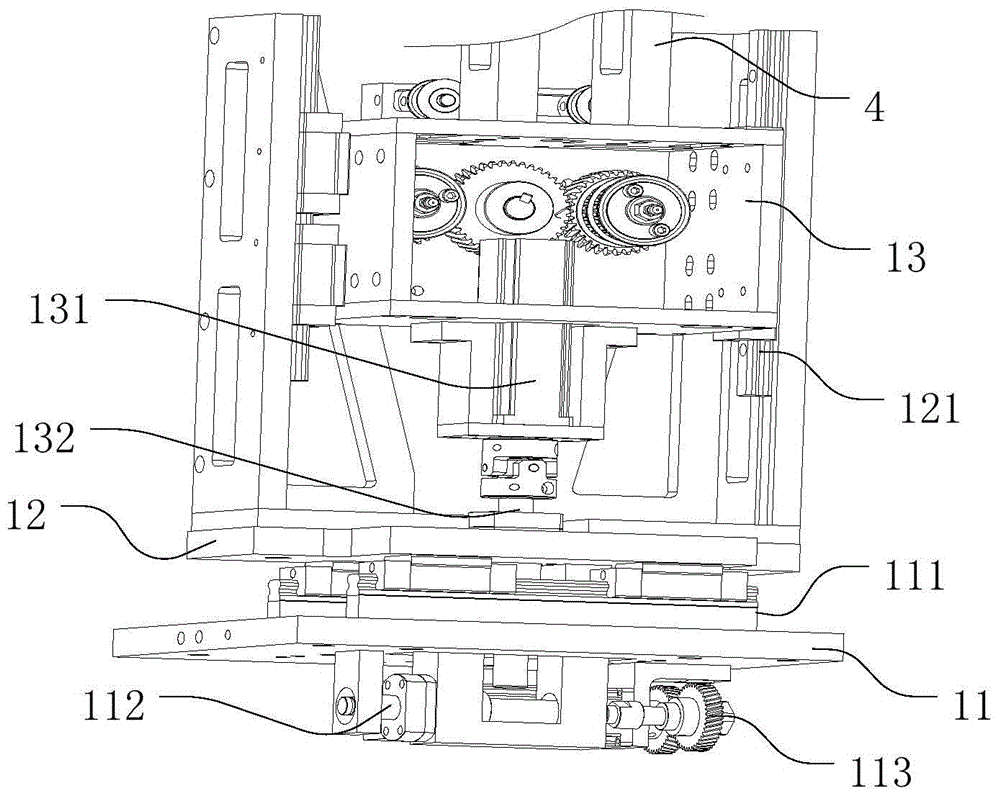

[0032] An embodiment of the present invention provides a multifunctional double-sided edging device for a machete machine, which combines Figure 1 to Figure 4 Shown, comprise: driving mechanism 1, grinding disc drive motor 2, blade guide frame 3, the grinding disc installation frame 4 that is positioned at blade guide frame guide rail 31 both sides, the guide rail 31 of blade guide frame 3 is set to horizontal longitudinal, each A grinding disc installation frame 4 is vertically distributed with a triangular grinding disc and a rectangular grinding disc on one side facing the guide frame 3 (two kinds of grinding discs in the figure adopt the same label 9), and the triangular grinding disc and the rectangular grinding disc are installed vertically. The installation sequence in the vertical direction can be interchanged. The position corresponding to the grinding disc on both sides of the blade guide frame guide track 31 is provided with a vertical opening 32, so that the grindi...

Embodiment 2

[0042] This embodiment provides a machete machine, which includes an edging device, and the edging device adopts the multifunctional double-sided edging device for a machete machine in the above-mentioned embodiment 1. The specific edging For the structure and working principle of the device, reference may be made to the above-mentioned Embodiment 1, which will not be repeated here. For other devices in the machete machine, such as the punching device and the machete device, existing devices can be used to realize them, and details will not be repeated here.

Embodiment 3

[0044] Based on the multi-functional double-sided edging device for machete machines in the above-mentioned embodiment 1 as the hardware basis, the present embodiment provides the edging method of the multi-functional double-sided edging device for machetes, such as Figure 5 shown, including the following steps:

[0045] 1001: Obtain setting parameters. The setting parameters include the setting position when the blade is transported. The setting position is the processing station of the grinding and cutting device. The blade is transported to this station by the blade conveying device on the machete machine. It can be realized by means of sensor detection or setting of the conveying distance. In this embodiment, the conveying distance is set, and it only needs to detect that the conveying distance is equal to the set distance.

[0046] 1002: When the blade moves to the set position, judge the shape to be processed of the blade at the set position according to the set parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com