Numerical control bending integrated forming machine

A forming machine and integrated technology, applied in the field of mechanical processing, can solve the problems of inability to realize bending, discontinuity and stamping, etc., and achieve the effect of saving manpower, saving cost and improving wire feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, goals and effects of the present invention in detail, the following examples are given to describe the embodiments in detail with accompanying drawings.

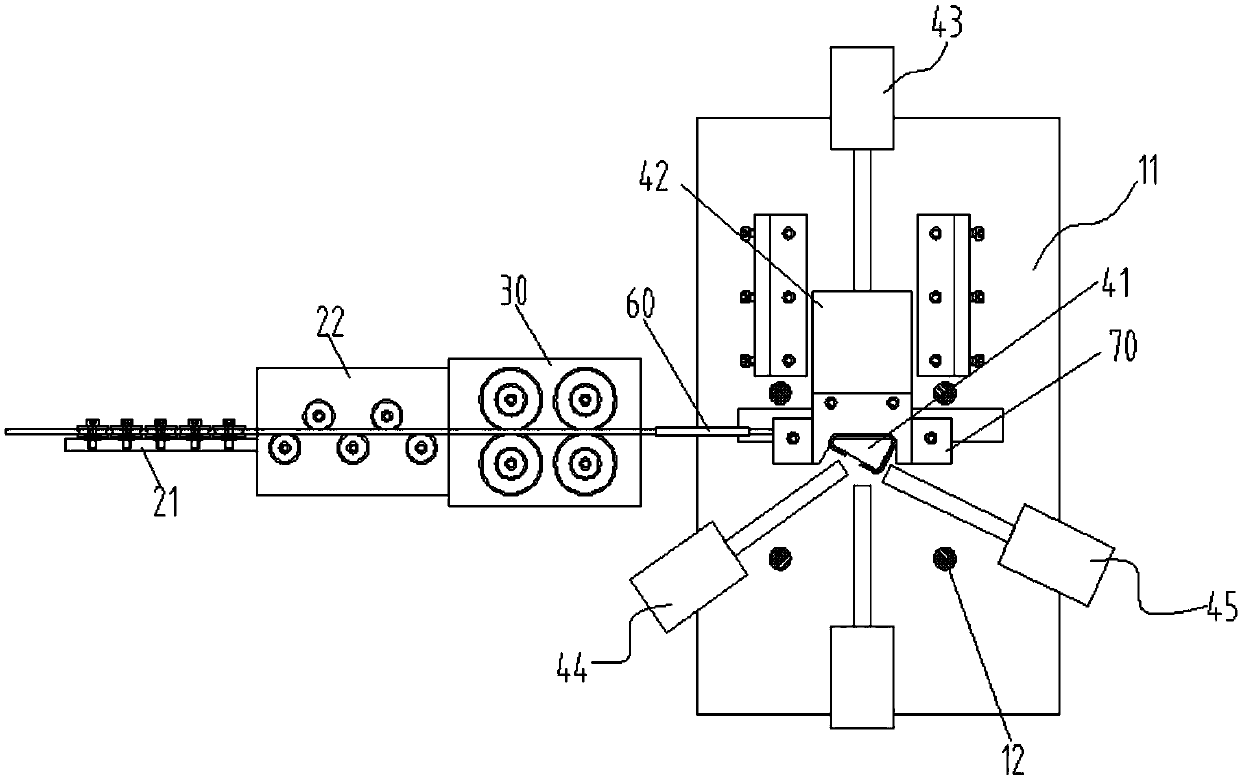

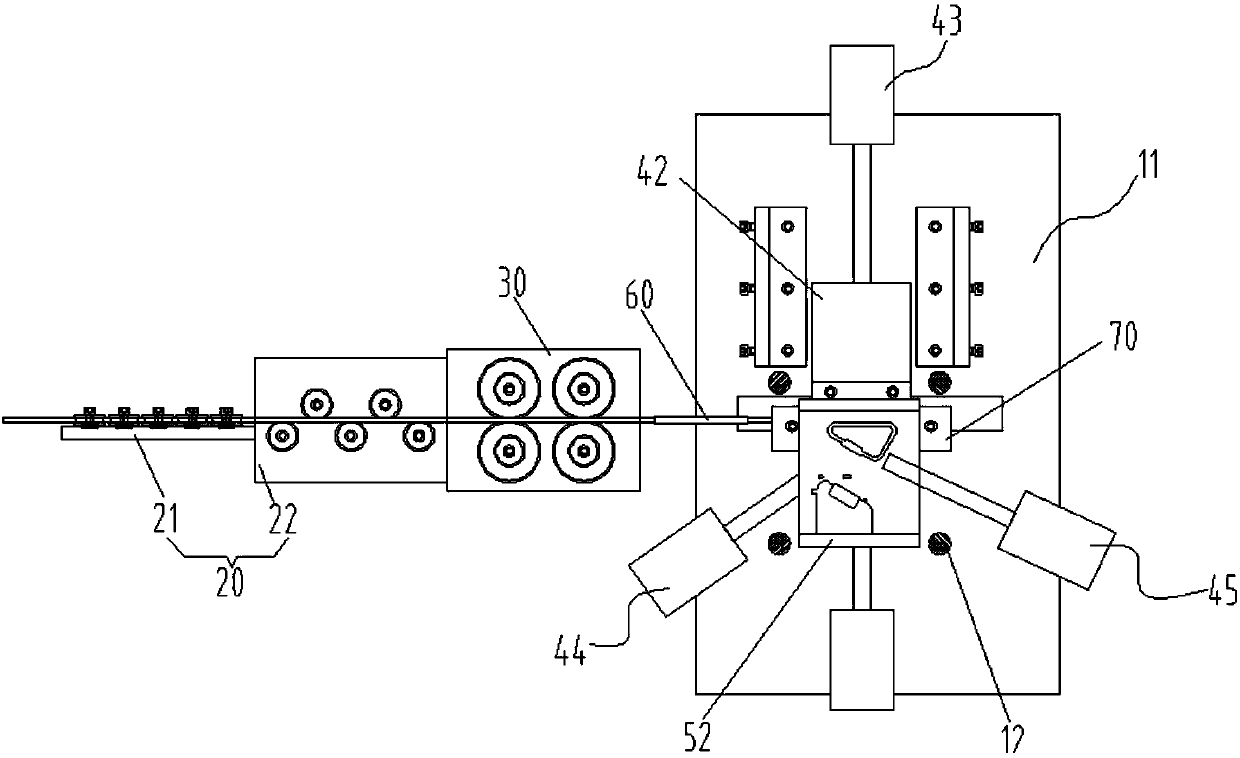

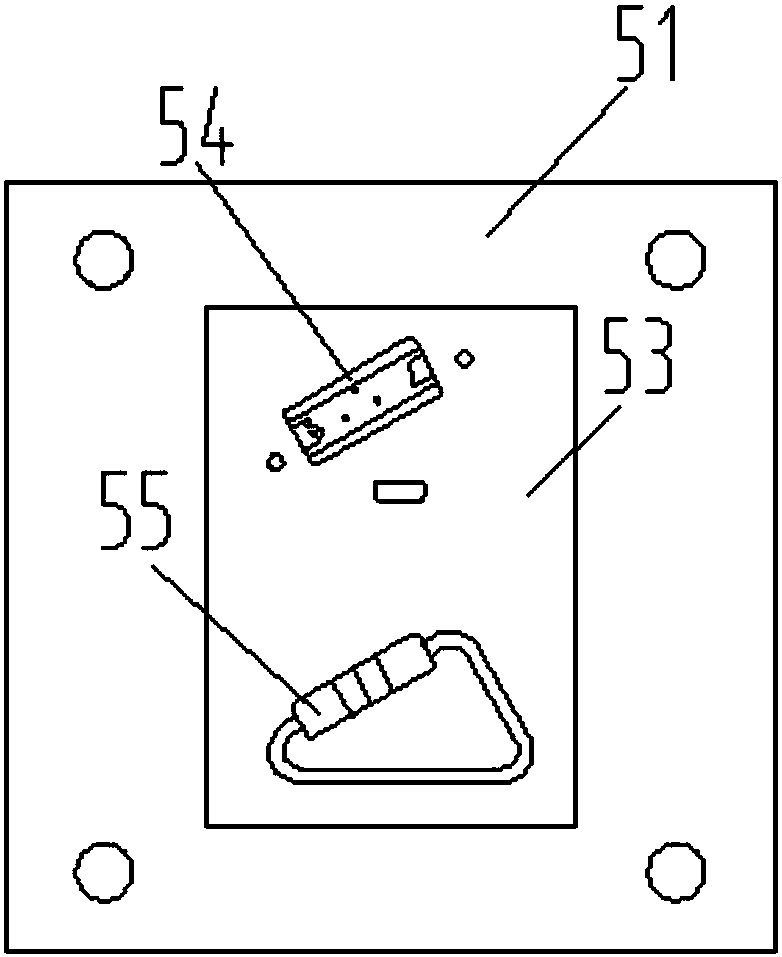

[0027] see figure 1 As shown, the present invention provides a kind of numerical control bending integrated molding machine, comprises frame, PLC control device and the straightening device 20 that is installed on the frame sequentially, guiding feeding device 30, bending device and stamping device, frame Comprise the base plate 11 that installs bending device and stamping device, wherein, bending device includes the bending die that is used to make the workpiece bending shape that is made of fixed die 41 and several movable dies 42, and is used for driving The driving device for the movement of the mold 42 relative to the fixed mold 41, the movable mold 42 and the fixed mold 41 are arranged on the same plane of the substrate 11 and oppositely arranged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com