Support positioner

A locator and support technology, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve problems such as tight fit, scratches on the product surface, and difficult control of the tolerance of the lug locator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

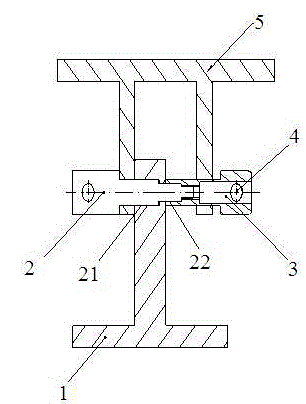

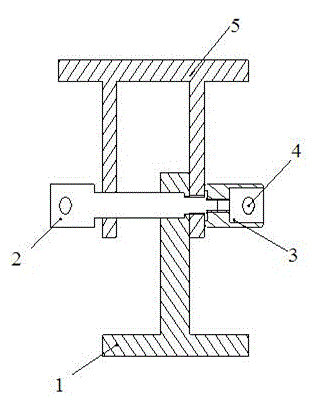

[0011] Such as figure 1 As shown, the support locator is composed of a support 1, a threaded pin 2, a nut 3 and a handle 4; the threaded pin 2 is provided with a first step 21 and a second step 22 whose diameter decreases step by step, and the end is a threaded section ; The support 1 involves a stepped hole, the first-level hole cooperates with the first-level step 21 of the threaded pin 2, the second-level hole cooperates with the second-level step 22 of the threaded pin 2, and the first-level step 21 is matched with the positioning hole of the workpiece 5 to be positioned Cooperate, the nut 3 is provided with an extension section, the outer diameter of the extension section cooperates with the positioning hole of the workpiece 5 to be positioned, the inner hole at the outer end of the extension section cooperates with the secondary step 22 of the threaded pin 2, and the internal thread at the outer end of the extension section matches the threaded pin 2, and the nut 3 is al...

Embodiment 2

[0014] Such as figure 1 As shown, the support locator is composed of a support 1, a threaded pin 2, a nut 3 and a handle 4; the threaded pin 2 is provided with a first step 21 and a second step 22 whose diameter decreases step by step, and the end is a threaded section ; Relate to the stepped hole on the support 1, the first-level hole cooperates with the first-level step 21 of the threaded pin 2, the second-level hole cooperates with the second-level step 22 of the threaded pin 2, and the large positioning of the first-level step 21 and the workpiece 5 to be positioned Hole fits, the secondary step 22 of threaded pin 2 cooperates with the small positioning hole of positioning workpiece 5, the internal thread of nut 3 cooperates with the threaded section of threaded pin 2, and nut 3 is also provided with handle 4, easy to use.

[0015] For the workpiece 5 to be positioned with unequal holes, the first-level step 21 of the threaded pin 2 passes through the large positioning hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com