Universal mold and pressing method for wooden and bamboo curved panels with multi-plunger oil cylinder

A general-purpose mold and multi-plunger technology, which is applied to household appliances, other household appliances, wood processing appliances, etc., can solve the problems of difficult mold making technology, high cost of opening molds, and occupying a lot of indoor space. The effect of less delay in working hours and small stacking space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

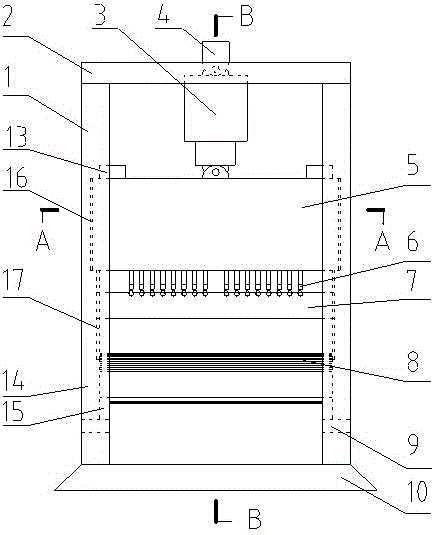

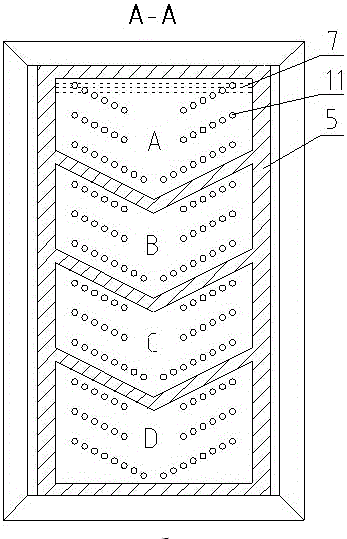

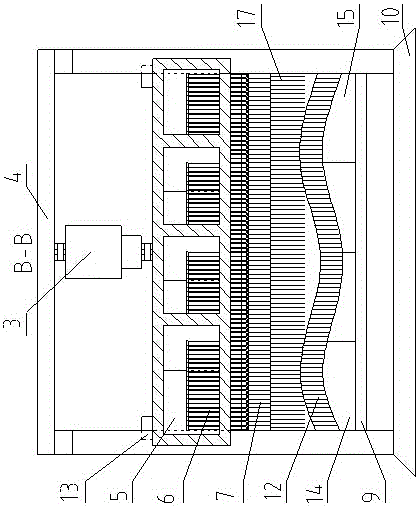

[0022] The present invention is described in detail below in conjunction with embodiment and with reference to accompanying drawing: See Fig. 1-7 , the general mold for wood and bamboo curved panels with multi-plunger oil cylinders, including frame, upper mold, lower mold and hydraulic mechanism, with hanging beams from top to bottom 4 ,Upper beam 2 ,lift 3 , Bearing block 13 , multi-plunger cylinder 5 , on the template 7 , the next template 8 , base 10 , with a side plate on each side 14 , the inner wall of the two side plates is opposite to the slideway of the multi-plunger cylinder 16 , upper formwork slide 17 , rung 9 , the lifter is respectively connected to the suspension beam and the multi-plunger oil cylinder up and down, and each plunger rod of the multi-plunger oil cylinder is covered with a return spring, and the plunger rod 6 The upper section of the cylinder is cylindrical, the lower section is narrow and flat, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com