Production method of anti-counterfeiting nylon mesh bag

An anti-counterfeiting nylon mesh bag and production method technology, applied in the field of seed cotton packaging, can solve the problems of weight reduction and damage to consumers' legitimate rights and interests, and achieve the effects of easy unpacking, protection of legal rights and interests, and prevention of leakage and adulteration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

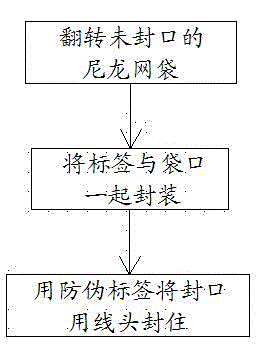

[0011] see figure 1 , a production method of anti-counterfeiting nylon net bag, it may further comprise the steps:

[0012] Turn the unsealed nylon mesh bag over so that the bottom and side edges of the bag are turned over to the inside of the mesh bag;

[0013] After the seed cotton or woolseed is weighed and packed into the mesh bag, the label is sealed together with the mouth of the bag;

[0014] Finally, fold the anti-counterfeit label in half and seal the seal with a thread.

[0015] The present invention turns over the unsealed ordinary nylon mesh belt, so that the bottom and side edges are located inside the bag body, so that the mesh bag cannot be disassembled from the bottom and sides unless it is not forced. Or wool seeds are weighed and packed into mesh bags, and then the labels printed with the company's trademark pattern, origin, producer name, weight, batch, date, and signature are sealed on the edge of the top of the bag, and finally the The anti-counterfeit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com