A method for protecting Lactobacillus by cross-linking soybean protein isolate with transglutaminase

A soybean protein isolate, transglutaminase technology, applied in microorganism-based methods, biochemical equipment and methods, immobilized on/in organic carriers, etc., can solve problems such as limiting the application of microcapsule products, toxicity, etc., To achieve the effect of good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of concentrated bacterial suspension:

[0031] Add the Lactobacillus rhamnosus LGG culture solution into the centrifuge tube, centrifuge at 6000r / min for 15min at 4°C, and discard the supernatant. The bacteria slime was washed twice under the same centrifugation conditions with equal volume of physiological saline (0.9% NaCl solution), and the bacteria sludge was resuspended with 1 / 10 volume of the original bacteria solution in normal saline to obtain a ten-fold concentrated bacterial suspension.

Embodiment 2

[0033] Optimization of Preparation Conditions of LGG Microcapsules

[0034] The optimal enzyme addition amount, cross-linking time, cross-linking temperature, and cross-linking pH were determined by single factor and response surface experiments.

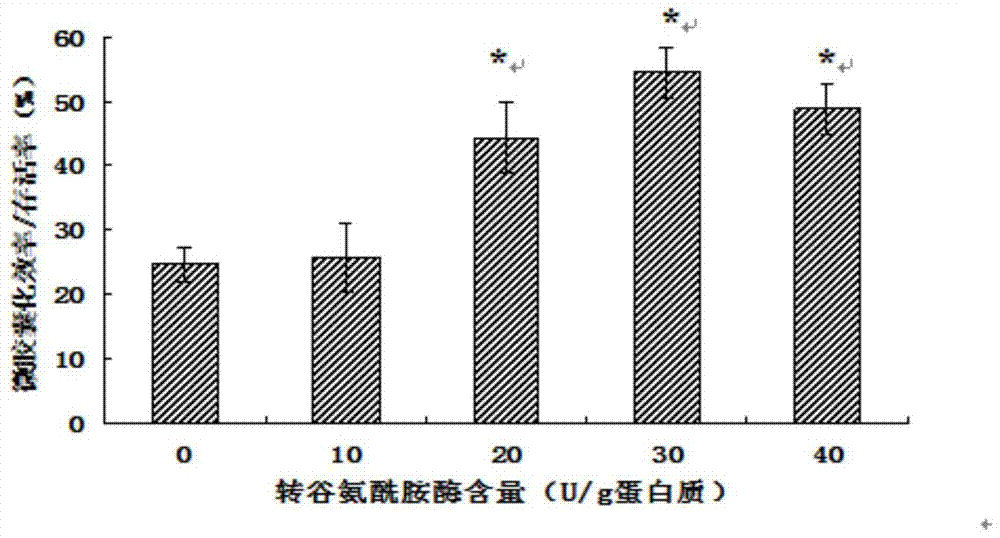

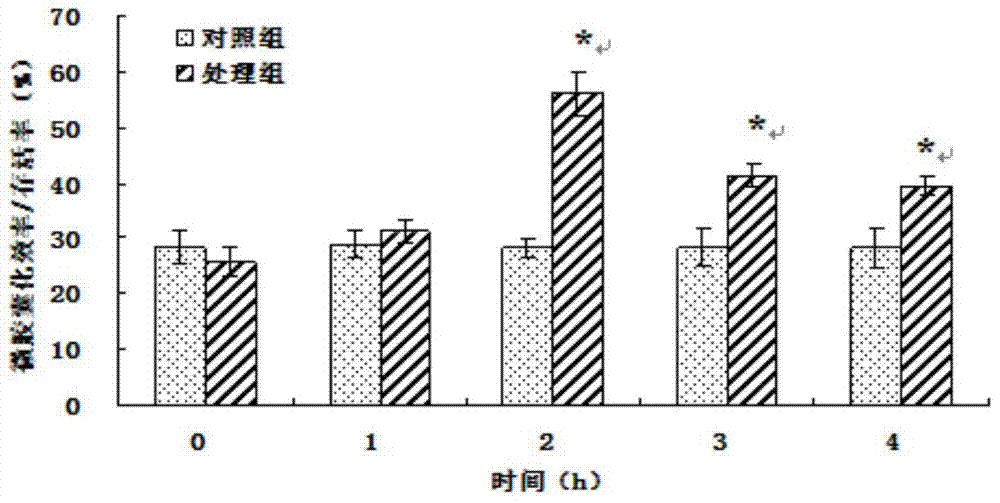

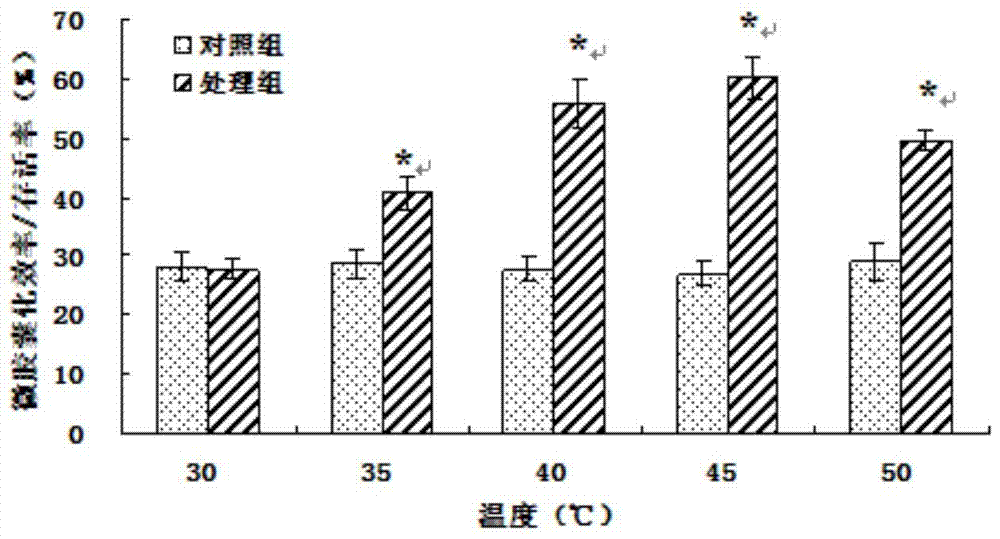

[0035] For the results of the single factor test, see Figure 1-4 , the response surface test design and results are shown in Table 1, and the variance and significance test analysis of the regression model are shown in Table 2.

[0036] Table 1

[0037]

[0038] Table 2

[0039]

[0040] Conclusion: Using Design-Expert 7.0 software to obtain the optimal microcapsule preparation conditions: the amount of TGase added is 30.8U / g protein, the cross-linking time is 2.2h, the cross-linking temperature is 42°C, and the cross-linking pH is 7.4, the predicted microencapsulation The efficiency is 68.3%. The verification test was carried out under this condition, and the actual measured microencapsulation efficiency was 67.4±2.7%, a...

Embodiment 3

[0042] Preparation of Lactobacillus rhamnosus LGG microcapsules

[0043] Prepare a 7% (w / w) soybean protein isolate solution with sterilized distilled water, adjust the protein pH to 7.4 with 1mol / L HCl (HCl is sterilized with a 0.22 μm filter membrane), and add transgenic protein at a concentration of 30.8 U / g. Glutaminase (TGase), stirred evenly with a magnetic stirrer, cross-linked at 42°C for 2.2h, immediately cooled in an ice-water bath, and then stored in a 4°C refrigerator for later use. Take 2 mL of the concentrated bacterial suspension and add it to 18 g of transglutaminase-crosslinked soybean protein isolate solution, stir evenly, pre-freeze at -20°C for 10 h, and vacuum freeze-dry for 12 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com