Concrete pouring method for pile foundation

A technology for concrete and pile foundations, applied in the field of concrete pouring for pile foundations, can solve problems such as concrete segregation, achieve the effect of ensuring quality and avoiding broken piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

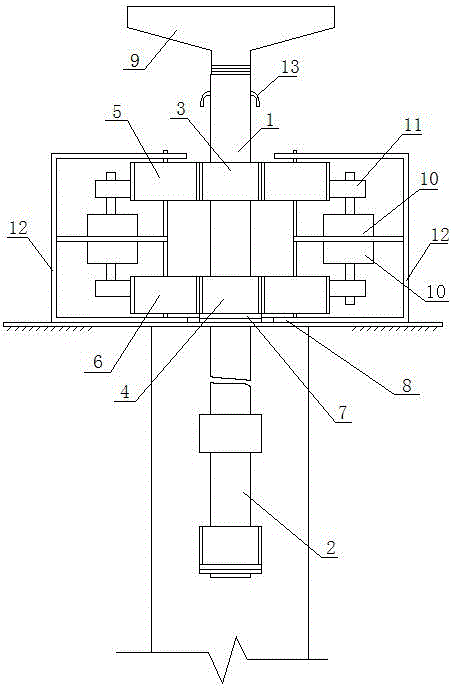

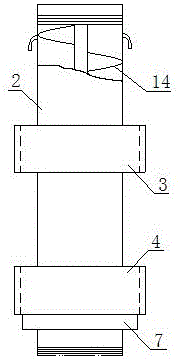

[0017] (1) The conduit for conveying concrete is formed by connecting multiple conduit units in sequence. The upper end of each conduit unit is provided with internal threads, and the lower end of each conduit unit is provided with external threads. The lower end of the first conduit unit 1 is connected to the second conduit unit. The upper end of the unit is threaded, so that multiple conduit units are connected in turn to form a conduit. An upper ring gear 3 is installed on the upper end of each conduit unit, and a lower ring gear 4 is installed on the lower end of each conduit unit. An axial bearing is arranged under the ring 4;

[0018] (2) A supporting platform 8 is set above the pile foundation. The supporting platform 8 is exactly a working surface for supporting. A circular hole suitable for the conduit is set on the supporting platform 8. Axial bearings are supported on the support platform 8, the so-called first section of conduit unit 1 is the uppermost section, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com