Improved anchoring part device

An anchor and improved technology, which is applied in covering/lining, building, building structure, etc., can solve the problems of damaged decorative panels, small installation stress area, and insufficient pulling force, so as to ensure the effect of heat preservation and heat insulation , Guarantee the anchoring strength and block the effect of hot and cold bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

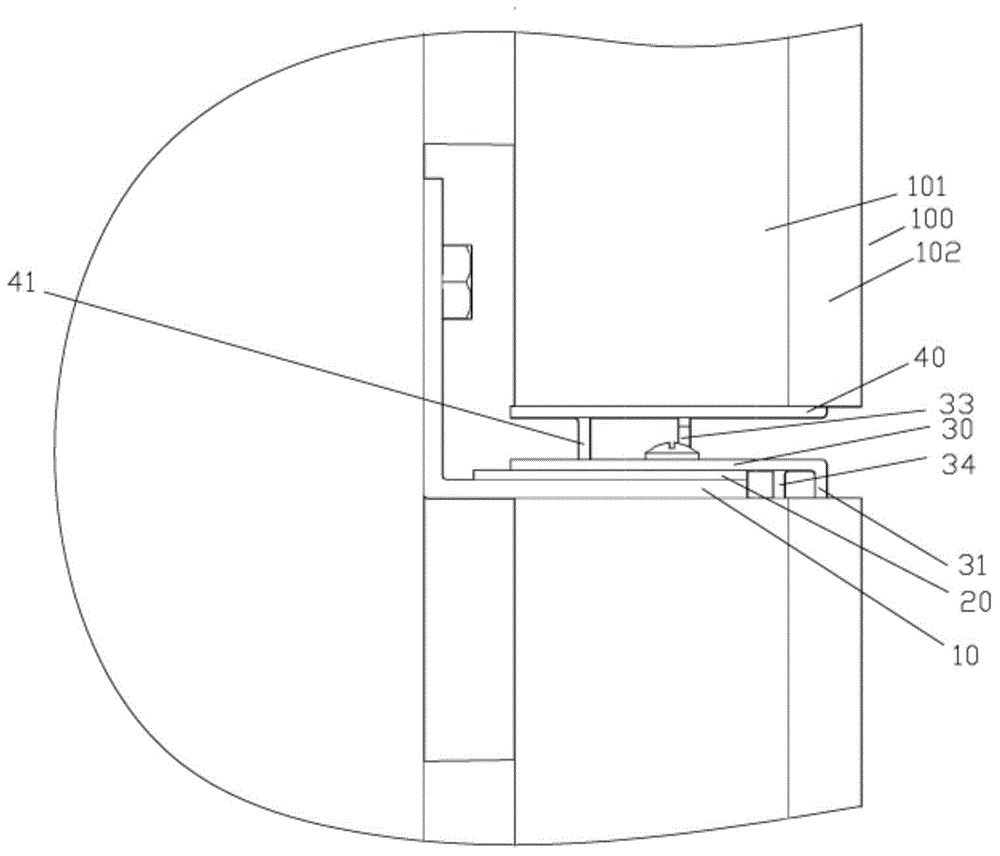

[0020] The technology of the present invention will be described in detail below in conjunction with the accompanying drawings and specific preferred embodiments, so that the advantages and characteristics of the technology of the present invention can be more easily understood by those skilled in the art. These embodiments are for illustrative purposes only and are not intended to The scope of the present invention is defined.

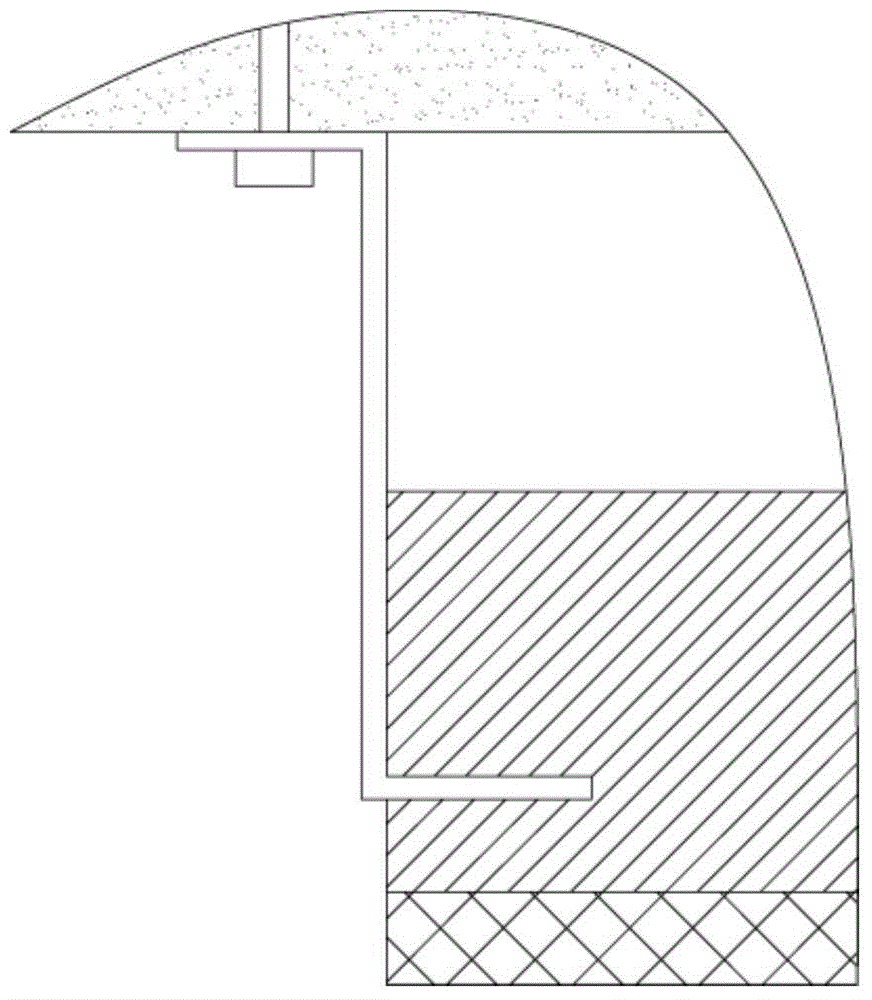

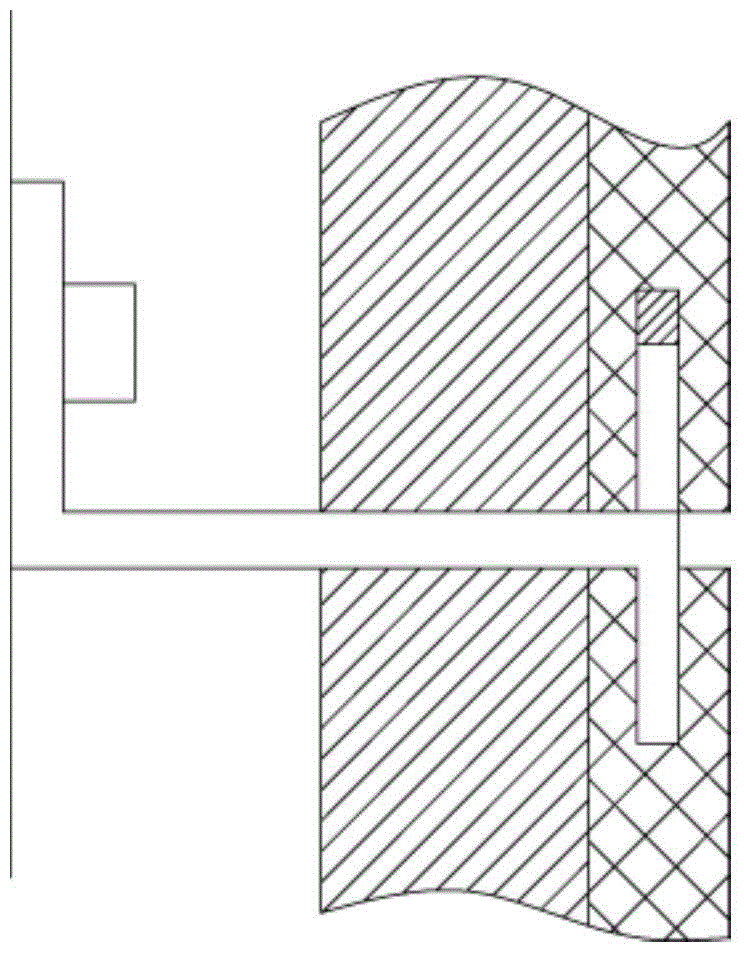

[0021] Examples, see e.g. Figures 3 to 5 As shown, an improved anchor device includes a fixed bracket 10, a thermal break 20 is placed on the top surface of the fixed bracket 10, and the lower fixed piece 30 is fixedly connected to the fixed bracket 10 by bolts, and the heat insulation The piece 20 is clamped between the lower fixing piece 30 and the fixing bracket 10, and the fixing bracket 10 is fixedly connected to the wall surface through fixing bolts, and the front end of the lower fixing piece 30 protrudes from the fixing bracket 10 and is bent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com