Novel serially-connected blowdown valve

A sewage valve, a new type of technology, applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of easy damage of sewage valve, easy damage of valve, and scouring of internal parts, so as to avoid damage, improve safety and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

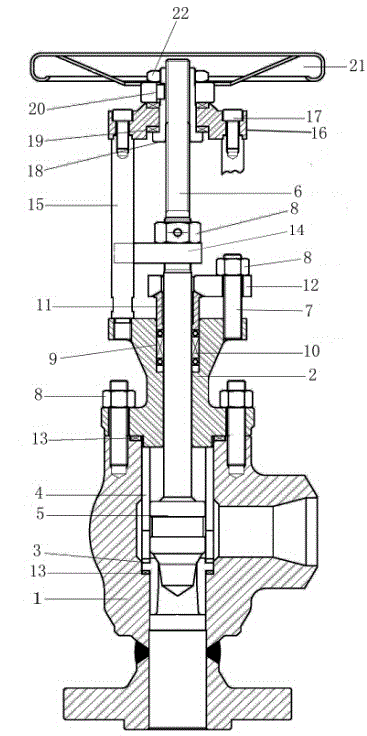

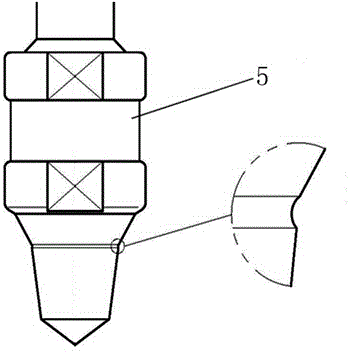

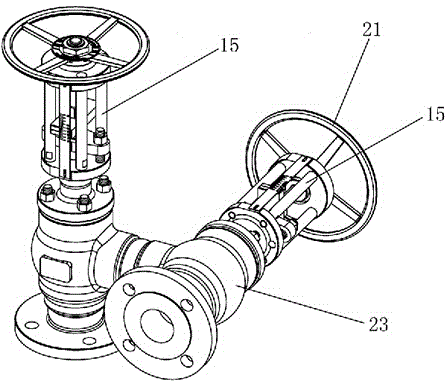

[0021] Such as Figure 1-3 As shown, a new series blowdown valve includes two blowdown valve units 23 connected in series by welding. The blowdown valve unit mainly includes valve body 1, upper cover 2, valve core assembly, valve seat 3, packing Letter 9, support vertical rod 15, screw seat 18, limit anti-rotation block 14 and hand wheel 21, the valve body 1 and the lower part of the upper cover 2 are connected by bolts 7 and nuts 8 to form a fluid pressure-bearing cavity, and It is sealed by a metal wound gasket 13 ; the upper part of the upper cover 2 is sealed by a stuffing box 9 . A valve core assembly is installed inside the pressure-bearing cavity, and the valve core assembly includes a sleeve 4, a valve core 5 and a valve stem 6. The sleeve 4 is directly pressed on the valve seat 3, and its upper end passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com