Integrated electromagnetic induction steam generation system

An electromagnetic induction and steam generation technology, applied in steam generation, steam generation method, climate sustainability, etc., can solve the problems of unrecyclable reuse, low steam generation efficiency, and small amount of steam generation, so as to improve the generation efficiency, The effect of flexible use and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

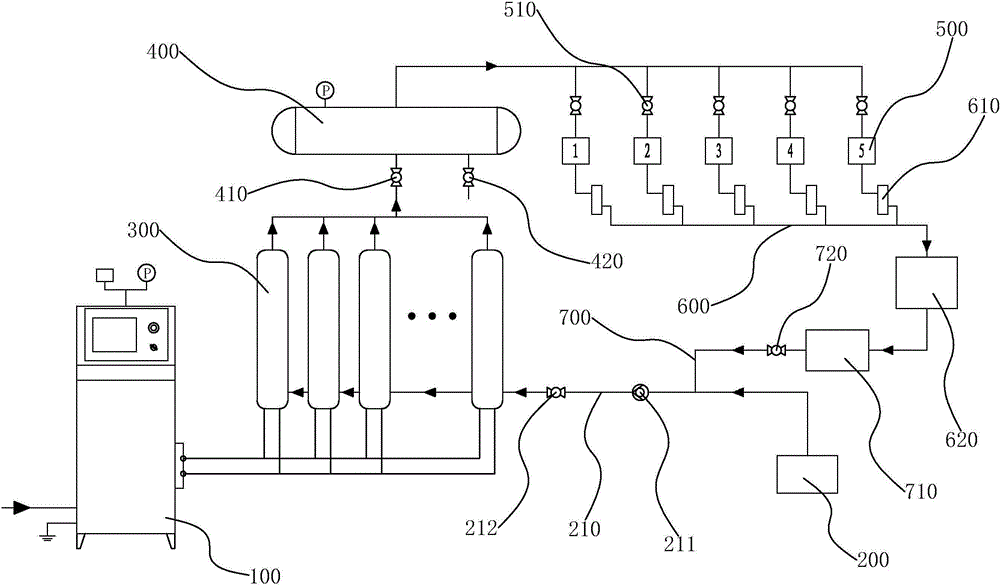

[0028] Such as figure 1 As shown, the integrated electromagnetic induction steam generation system includes a system controller 100, a water source tank 200, a steam generation unit, a gas collection unit, a gas consumption unit, and a recovery unit.

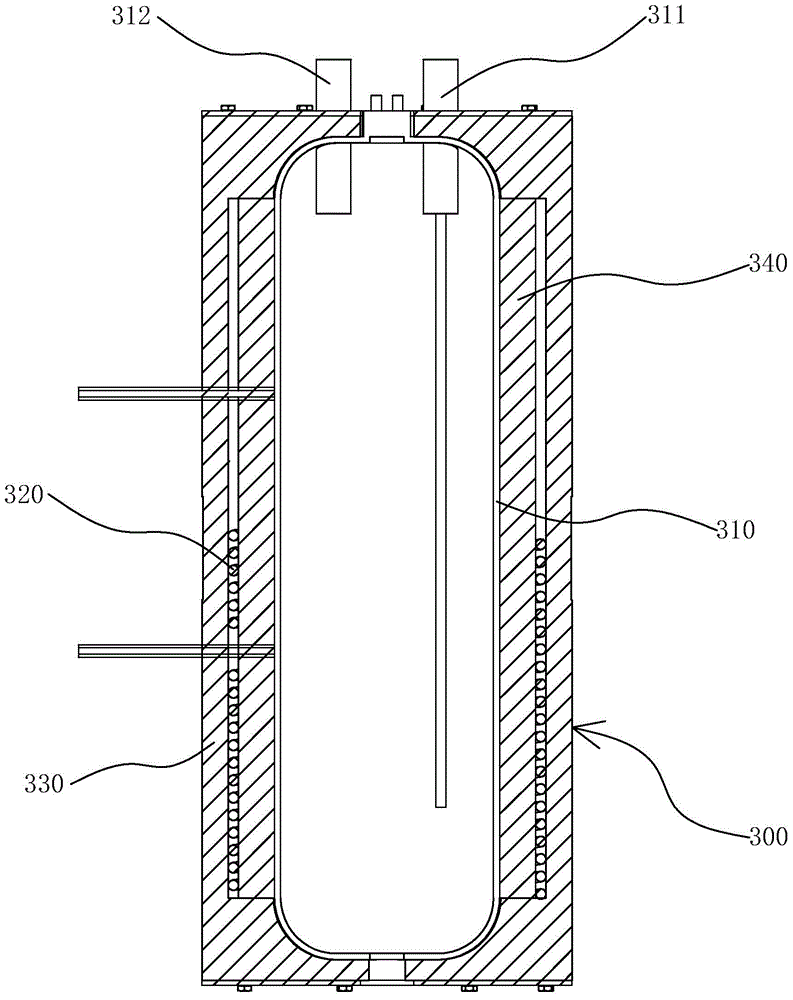

[0029] The steam generating unit includes a plurality of gas-making furnace bodies 300 connected in parallel and used to generate steam, such as figure 2 As shown, each gas-making furnace body 300 includes a gas-making furnace 310 and a conductive coil 320. The gas-making furnace 310 is empty and filled with water inside. The gas-making furnace 310 is provided with a water inlet 311 and an outlet. The gas pipe 312 and the conductive coil 320 are wound outside the gas-makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com