A method and system for predicting lamellar tear resistance of steel used in high-rise buildings

A technology of anti-lamellar tearing and performance prediction, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of friendly interface, easy operation and excellent universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Taking Q420EZ35 steel for high-rise buildings with a plate thickness of 80mm as an example, the process flow is: hot metal pre-desulfurization→converter smelting→LF refining→RH vacuum degassing→continuous casting on the continuous casting machine (the thickness of the continuous casting slab is 320mm), mainly hot rolling The process parameters are as follows: starting rolling temperature 1050-1150°C, finishing rolling temperature 830-890°C, crimping temperature 510-590°C, continuous casting speed = 0.65m / min, light reduction rate = 1.13mm / m.

[0058] Using MATLAB software to map the relationship between the existing rolling process parameters and lamellar tear resistance ( i = 1, 2, 3, j = 0, 1, 2, ..., k) for PLS calculation, the algorithm steps are as follows.

[0059] Step 1: Relevant process data of rolled samples (≥9), as shown in Table 1.

[0060] Table 1 Sample process parameters and test results

[0061]

[0062] Step 2: Investigate the issue of multiple c...

Embodiment 2

[0084] In order to fully illustrate the universality of the prediction method and system, take Q420D with a plate thickness of 40mm as an example. The process flow is: hot metal pre-desulfurization→converter smelting→LF refining→RH vacuum degassing→continuous casting on No. 3 continuous casting machine (Thickness of continuous casting slab is 220mm), the main process parameters are: starting rolling temperature 980~1080℃, final rolling temperature 830~870℃, crimping temperature 470~550℃, continuous casting speed=1.1m / min, light reduction rate = 1.11 mm / m. The modeling and optimization process and steps are the same as in Example 1.

[0085] Step 1: Relevant process data of rolled samples (≥9), as shown in Table 5.

[0086] Table 5 Sample process parameters and test results

[0087]

[0088] After step 2~step 4 described in embodiment 1, obtain the PLS prediction model of anti-lamellar tearing performance, Q420D high-rise building steel anti-lamellar tearing performance Ψ ...

Embodiment 3

[0096] Taking Q420GJEZ35 with a plate thickness of 60mm as an example, the process flow is: pre-desulfurization of molten iron→converter smelting→LF refining→RH vacuum degassing→continuous casting on No. 3 continuous casting machine (the thickness of the continuous casting slab is 220mm), the main process parameters are : Start rolling temperature 1030-1080°C, finish rolling temperature 840-880°C, coiling temperature 500-550°C, continuous casting speed = 1.1m / min, light reduction rate = 1.11mm / m. The modeling and optimization process and steps are the same as in Example 1.

[0097] Step 1: Relevant process data of rolled samples (≥9), as shown in Table 7.

[0098] Table 7 Sample process parameters and test results

[0099]

[0100] After step 2~step 4 described in embodiment 1, obtain the PLS predictive model of anti-lamellar tearing performance, Q420GJEZ355 high-rise building steel anti-lamellar tearing performance Ψ Z for:

[0101] Ψ Z =0.0211x 1 +0.0901x 2 +0.0697x...

PUM

| Property | Measurement | Unit |

|---|---|---|

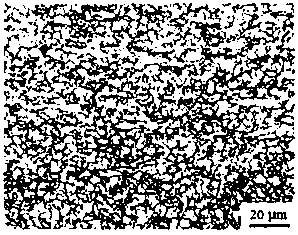

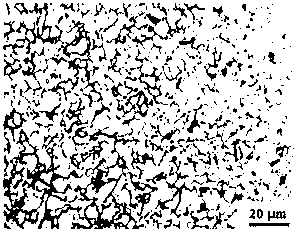

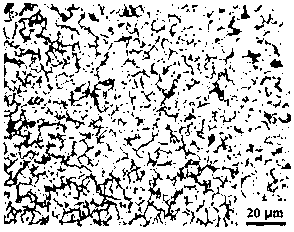

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com