High Thrust Servo Electric Cylinder

A servo electric cylinder and high thrust technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of easy free rotation of screw or screw nut, small thrust, high cost of use, etc., to improve stability and Practicality, improved output thrust, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

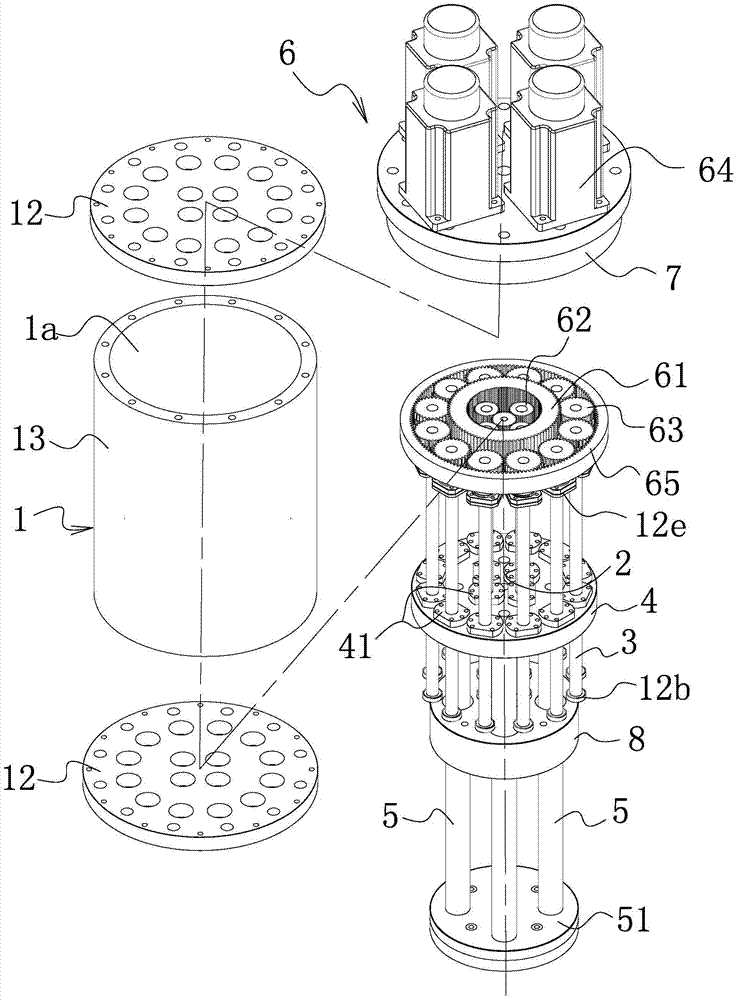

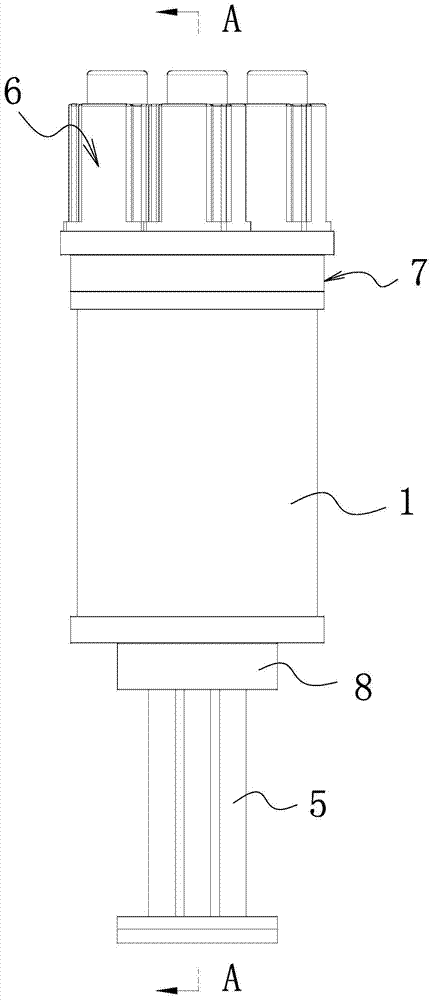

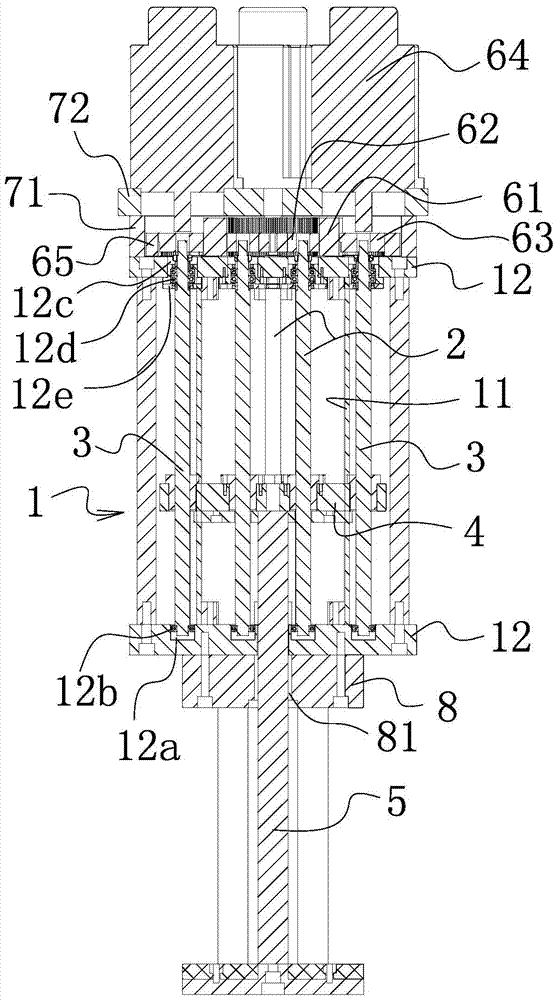

[0031] Such as Figure 1-6 As shown, the high-thrust servo electric cylinder includes a cylinder body 1 with a chamber 1a. The cylinder body 1 is provided with a number of inner screw rods 2 that are respectively pierced in the chamber 1a and are evenly distributed on the circumference so as to form a circle. The inner screw mandrel 2 enclosed in a circle is provided with an outer screw mandrel 3 which is evenly distributed in a number of circles so as to form at least one circle. on the push plate 4, and the inner screw rod 2 is threadedly connected with the push plate 4, and the outer screw rod 3 is threaded with the push plate 4, and a plurality of inner screw rods 2 and outer screw rods 3 are provided on the push plate to penetrate one by one. The screw guide sleeve 41 is provided with an internal thread on the inner wall of the screw guide sleeve, and the inner screw rod 2 and the outer screw rod 3 are connected with the internal thread threads of the corresponding screw ...

Embodiment 2

[0041] Such as Figure 7 As shown, the structure and principle of the present embodiment are basically the same as those of the first embodiment, which will not be repeated here. The difference is that the driving structure is a multi-point meshing flexible transmission device 66 . The multi-point meshing flexible transmission device is arranged at one end of the cylinder body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com