Automatic welding device for shoemaking

An automatic welding and shoe-use technology, which is applied in auxiliary devices, welding equipment, shoe-making machinery, etc., can solve the problems of increasing labor intensity and labor cost, and achieve the goal of reducing labor cost, good welding effect and fast efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

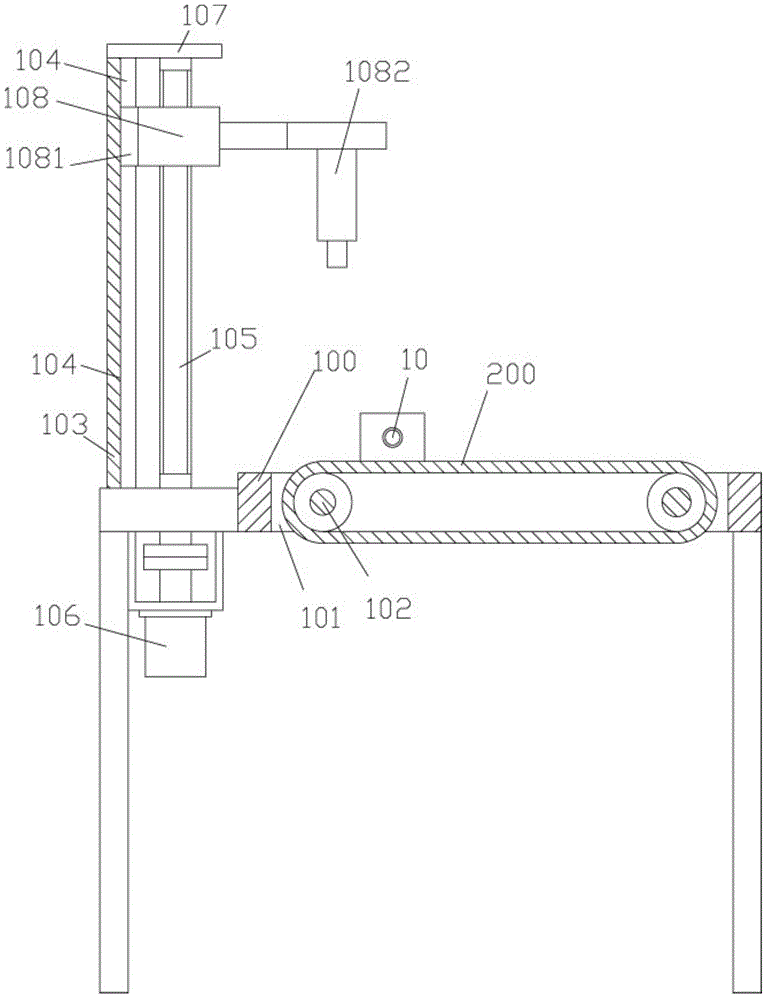

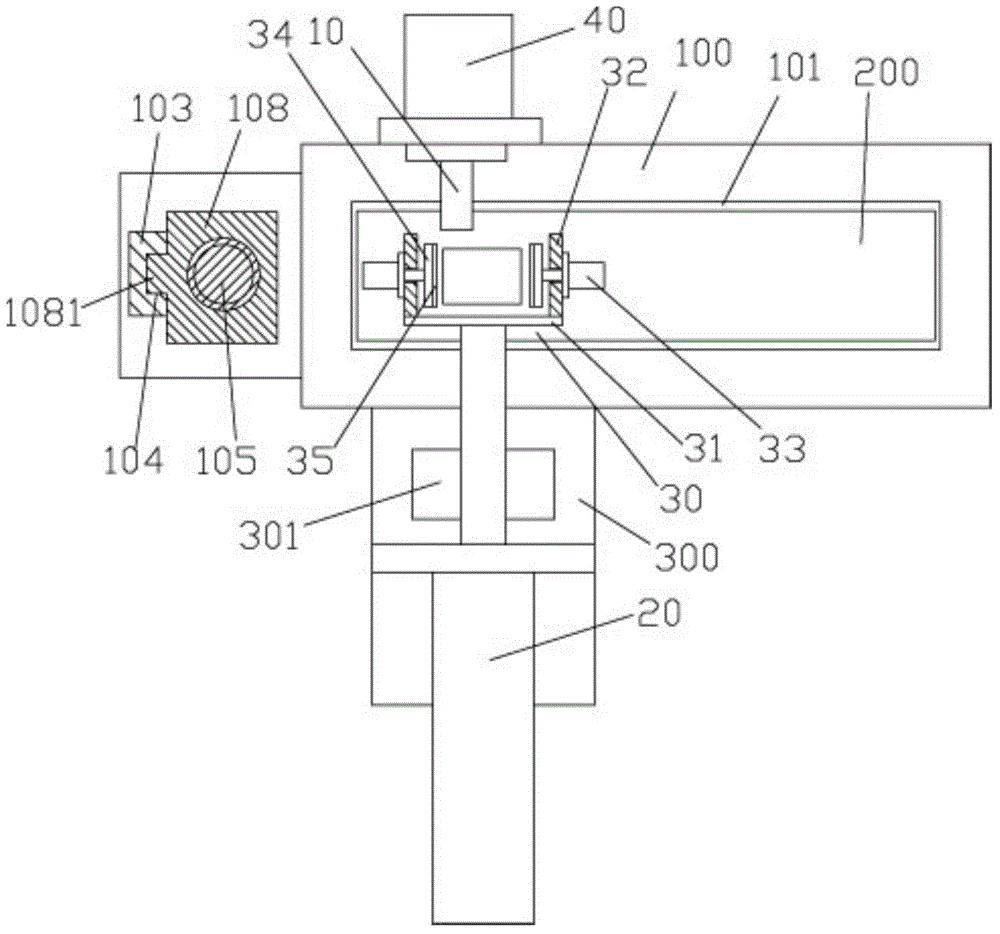

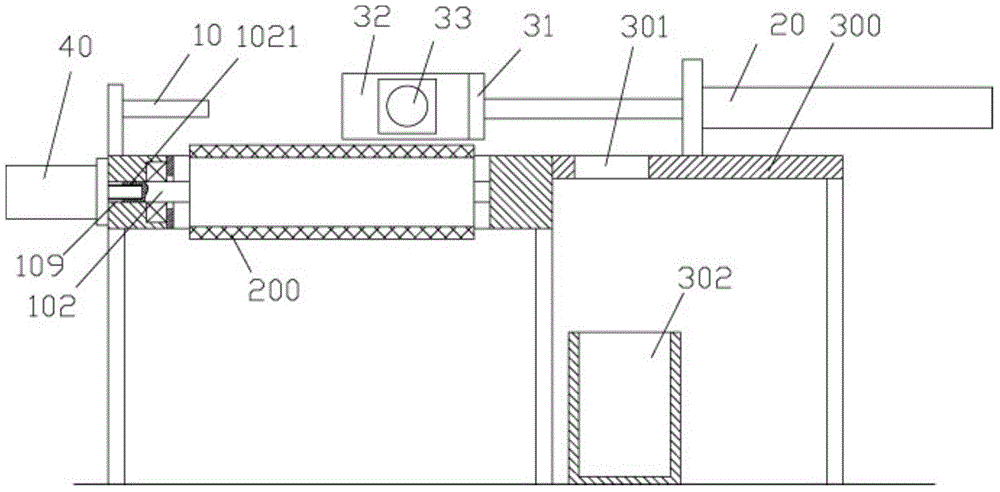

[0012] Examples, see e.g. Figures 1 to 3 As shown, an automatic welding device for shoemaking includes a frame 100, the middle part of the frame 100 has a conveyor belt through groove 101, two rotating rollers 102 are in the conveyor belt through groove 101, and the two ends of the rotating roller 102 Hinged on the front and rear side walls of the conveyor belt channel 101, the conveyor belt 200 is tensioned in the two rotating rollers 102, and the left side of the top plate of the frame 100 is fixed with a limit rod 103, and the limit rod 103 has a vertical groove 104, the lower part of the rotating screw 105 is hinged on the left side of the top plate of the frame 100, the left bottom of the frame 100 is fixed with a servo motor 106, and the lower end of the rotating screw 105 extends out of the left side of the top plate of the frame 100 and passes through the coupling Connected with the output shaft of the servo motor 106, the upper end of the rotating screw rod 105 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com