Laser machine

A laser machine and laser technology, applied in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve problems such as low efficiency, achieve the effects of improving efficiency, shortening waiting time, and realizing cycle automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

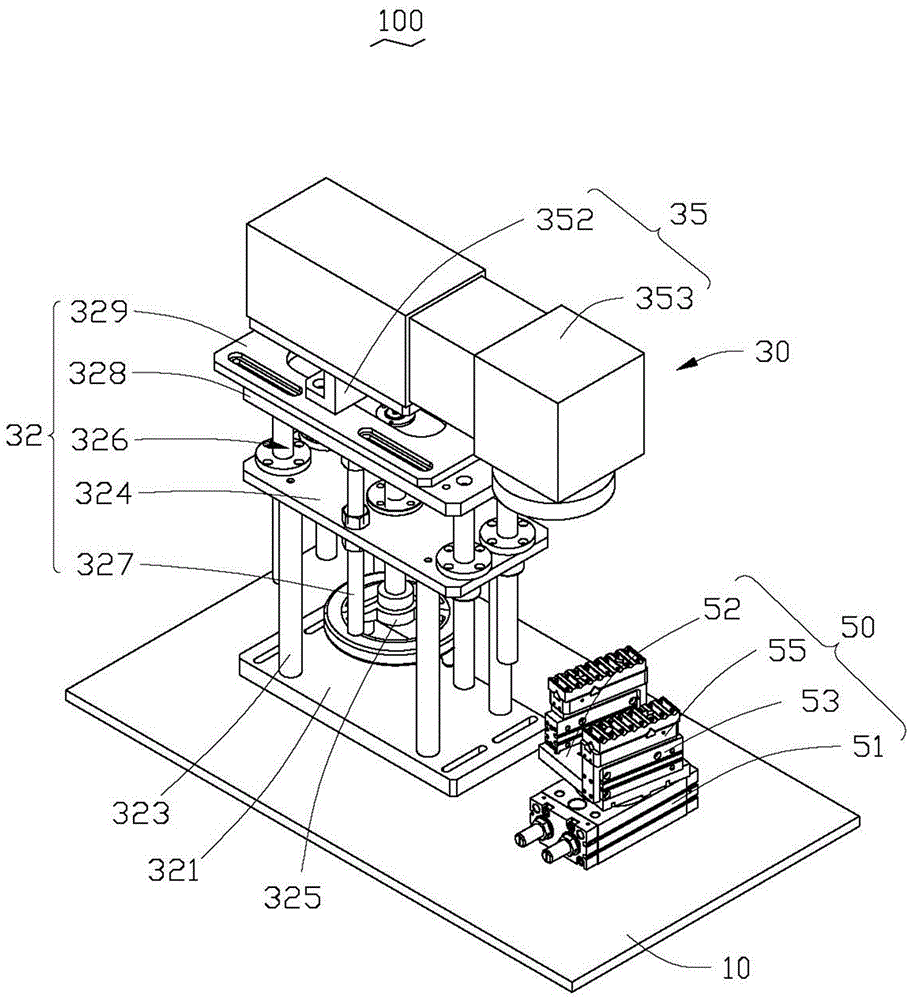

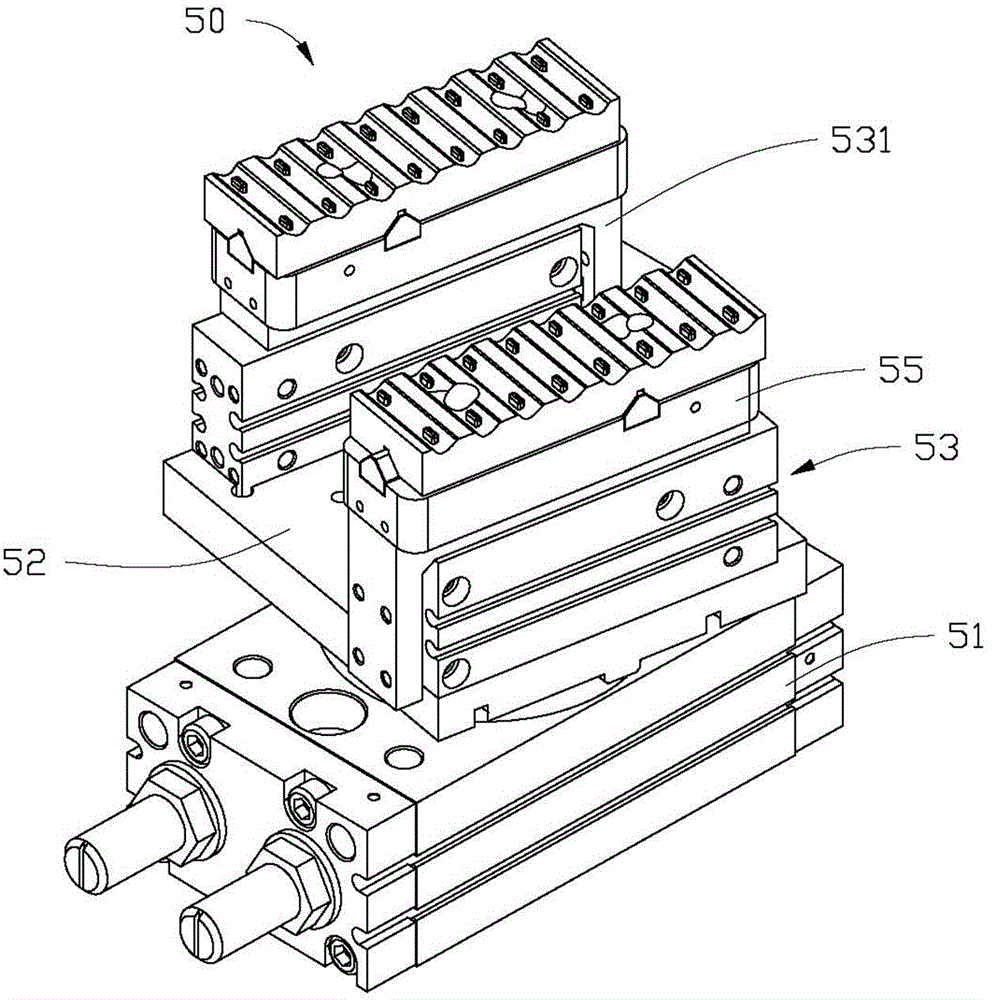

[0012] See figure 1 The preferred embodiment of the present invention provides a laser machine 100, which is used for laser marking or welding processes. In this embodiment, the laser machine 100 is applied to a marking process for description. The laser machine 100 includes a worktable 10, a laser device 30 and an object carrying device 50. The laser device 30 and the object carrying device 50 are installed on the workbench 10 opposite to each other. The workbench 10 can install at least one set of the laser device 30 and the object carrier 50. Both the laser device 30 and the object carrying device 50 are connected to an electric control box (not shown).

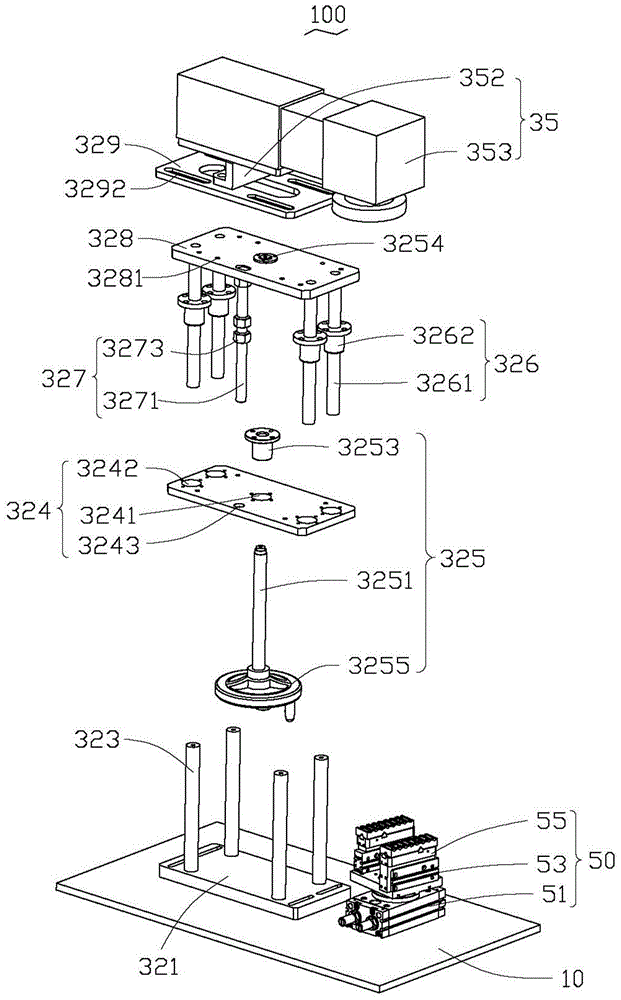

[0013] Please refer to figure 2 , The laser device 30 is used to generate laser light. The laser device 30 includes an adjusting component 32 and a laser component 35. The adjusting component 32 is used to adjust the position of the laser component 35. The adjusting assembly 32 includes a base 321, a plurality of support...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap