Cable clamping assembly for binding beam type cable

A cable and bundle-shaped technology, which is applied in the field of clamping components for bundling bundle-shaped cables, can solve the problems of inconvenient use, tangling into a mess, and hindering the use of the next tying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

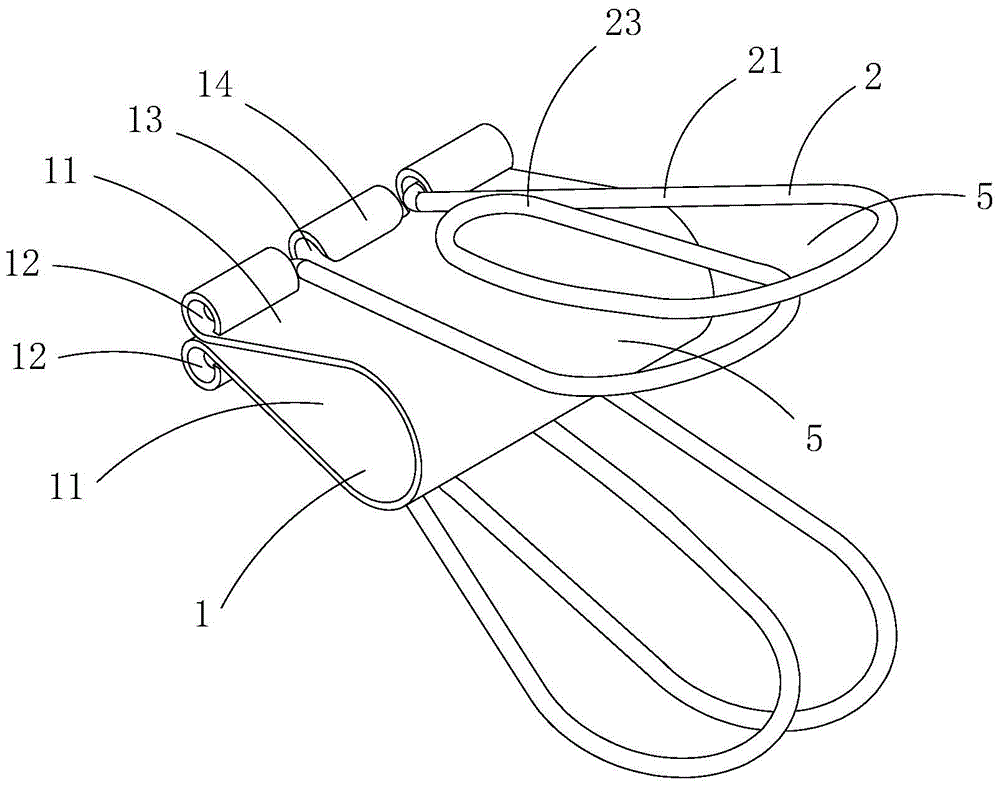

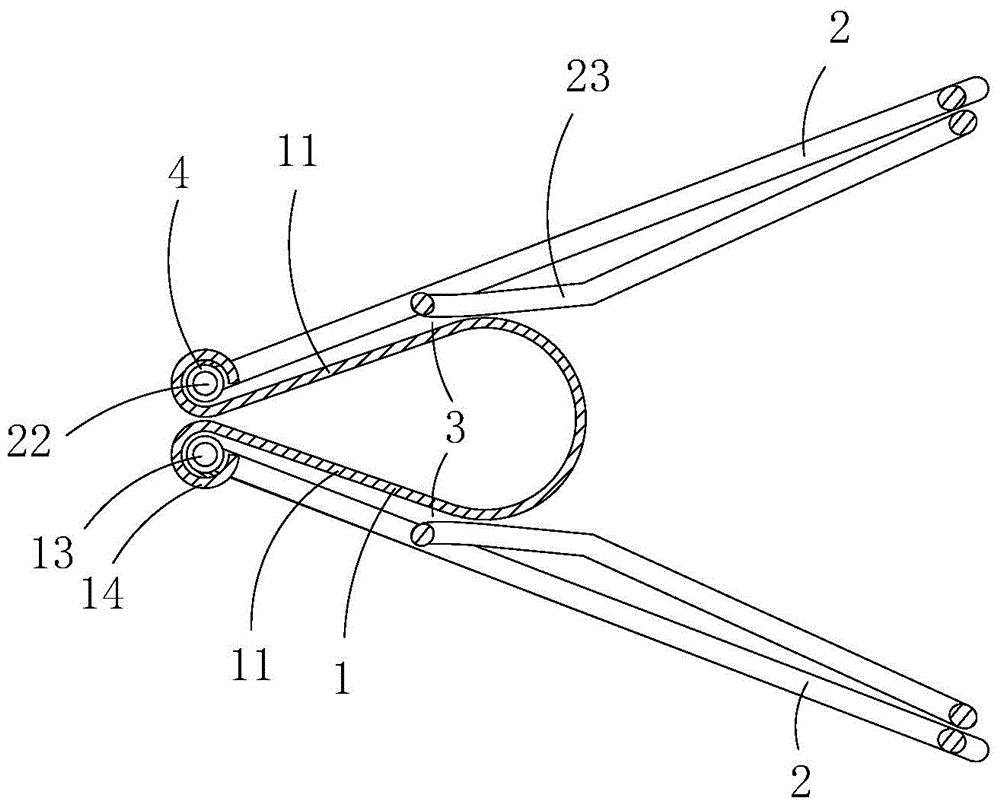

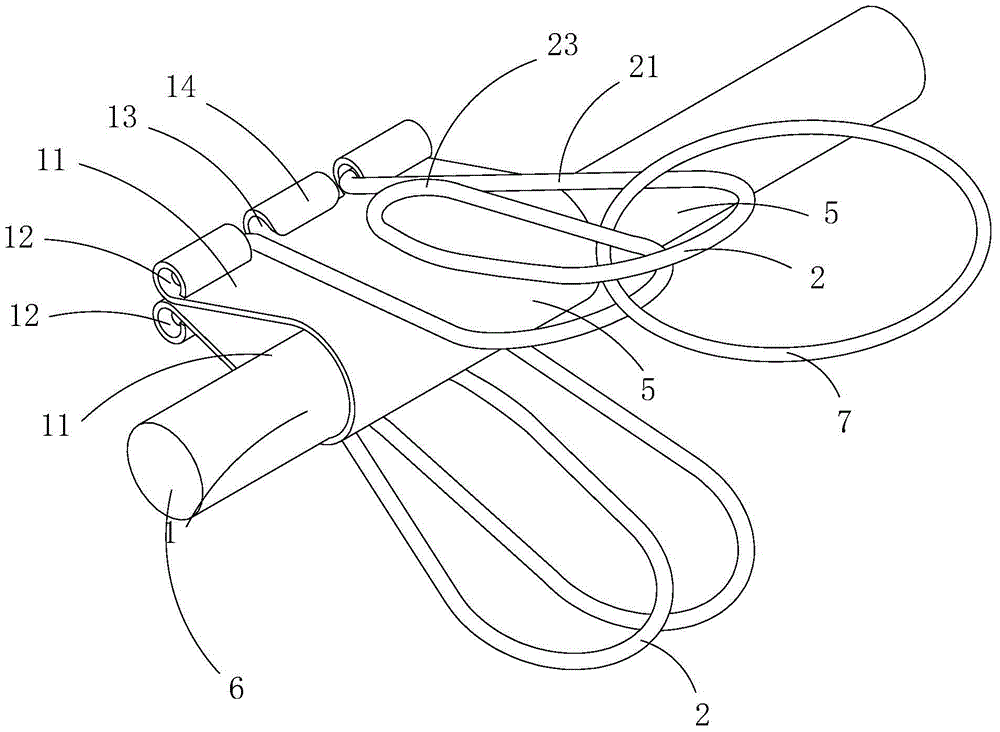

[0011] Figure 1 to Figure 3 A specific embodiment of the invention is shown in which, figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 yes figure 1 A cutaway view of the long tail clip shown; image 3 yes figure 1 A schematic diagram of the application of the long tail clip shown.

[0012] Present embodiment is a kind of long tail folder, see Figure 1 to Figure 2 , including a clamping piece 1 and two clamping handles 2; the clamping piece includes two splints 11 made in one piece, and the two sides of each splint end plate are bent and rolled back toward the outside of the splint to form two pin holes 12; each The clamping handle is made of steel wire, and each clamping handle includes two load-bearing parts 21. The two ends of the two load-bearing parts bundled cables are bent to form two pins 22, and each pin is inserted into a corresponding pin. In the hole; the middle part of each clamp handle is wound to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com