Condition monitoring of vertical transport equipment

A technology of vertical transmission and equipment, applied in the field of working conditions of mechanical brakes, it can solve problems such as complex and erroneous operation of the system, and achieve the effect of simplifying diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

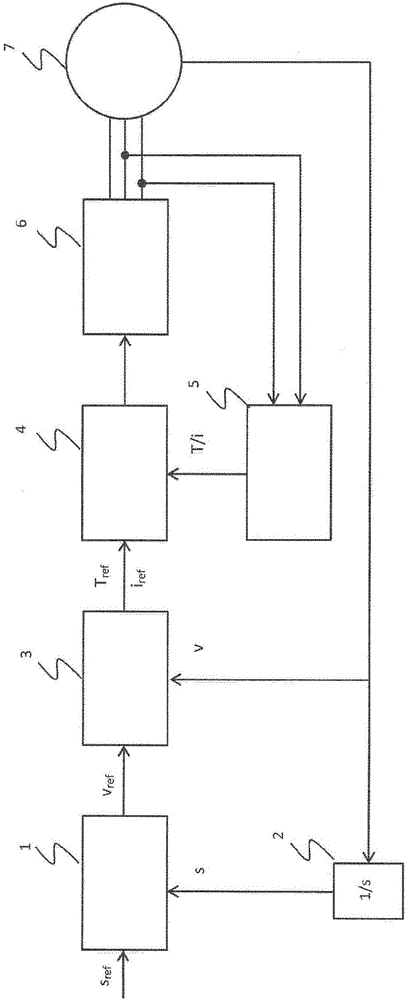

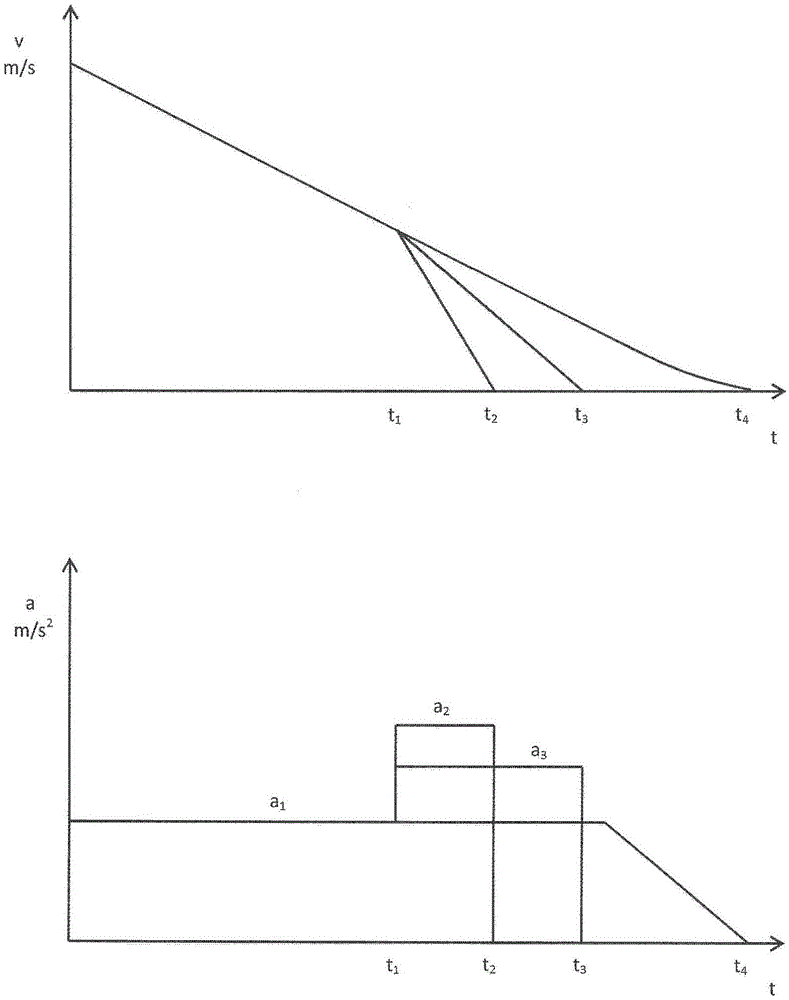

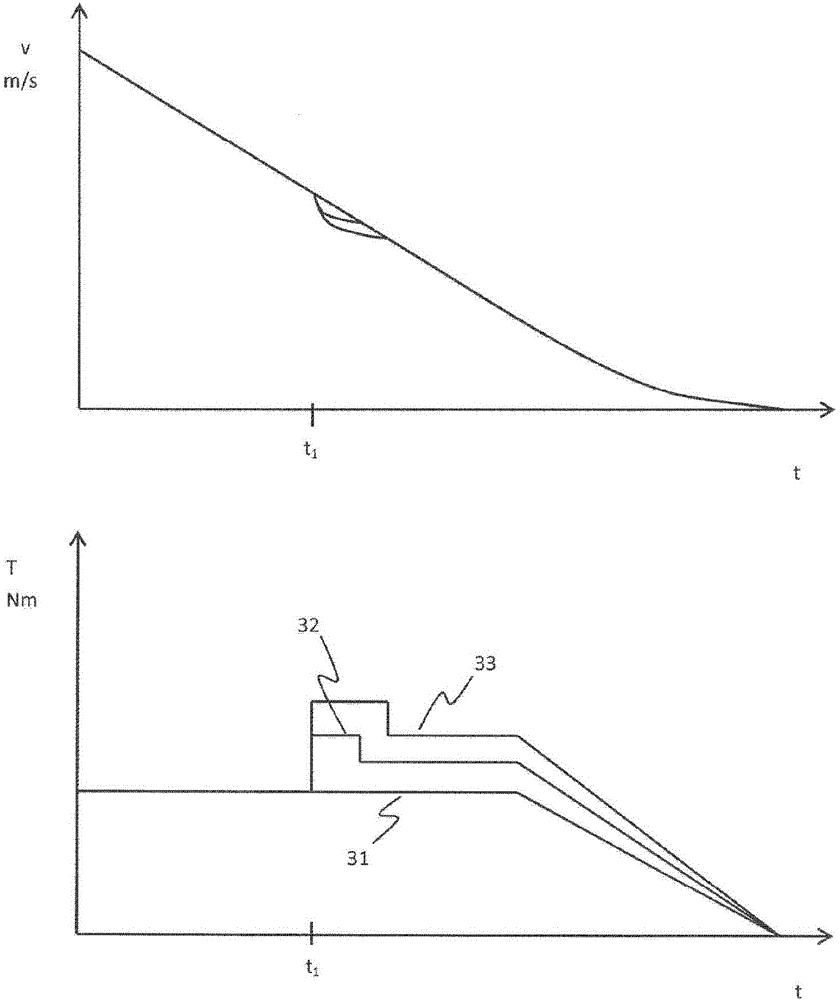

[0018] Many frequency converters enable mechanical brakes that can be used to brake the mechanical motion associated with the load of the frequency converter to be controlled. Frequency converters are used in elevators or other vertical transport equipment, and the frequency converter controls the movement of the load, ie the elevator car in the hoistway or the load of the crane. The drive is also able to control a mechanical brake to hold the load safely in place after the load has come to a standstill. Under normal operation, the frequency converter first controls the elevator car to the desired position based on the position information, and after reaching the desired position and after the elevator car stops moving, the frequency converter sends a command to the mechanical brake so that the brake is firmly fixed shaft of the rotor. With respect to a crane or lifting appliance, the stop position does not need to be predetermined so that when the crane user decides to stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com