Computerized flat knitting machine tucking connecting needle pressing leg driving device

A computerized flat knitting machine and transmission device technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as low work efficiency, achieve the effects of increasing service life, improving work efficiency, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

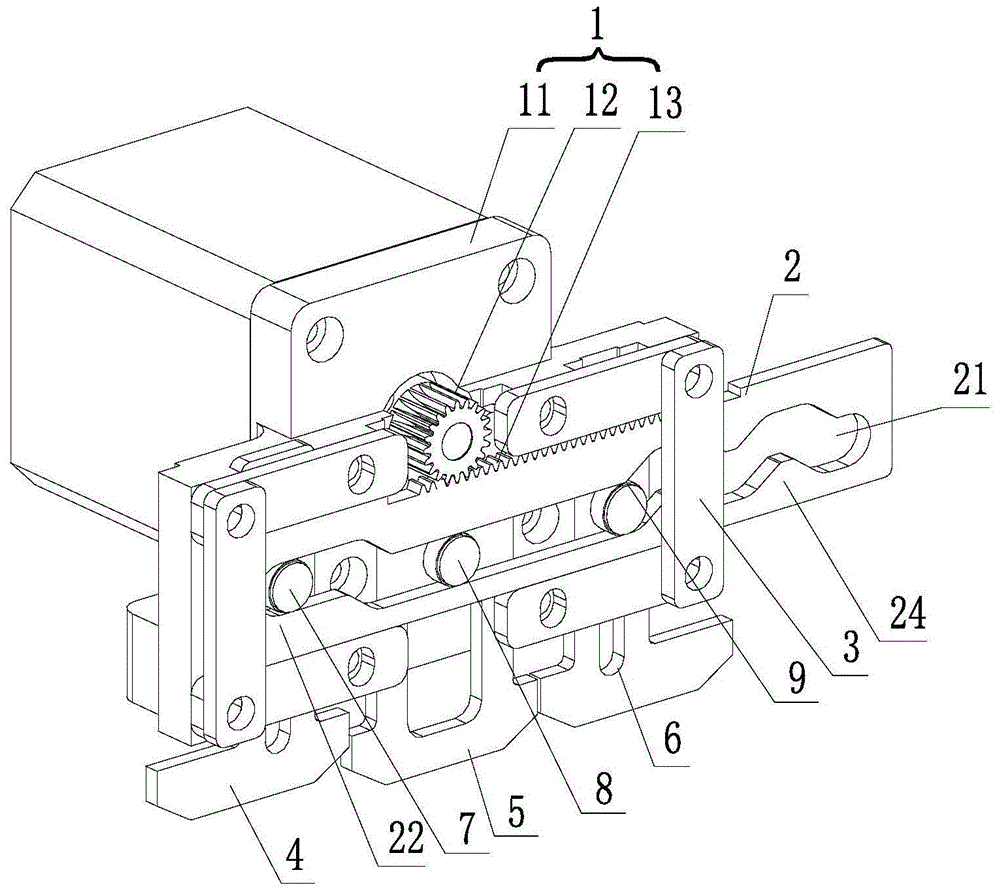

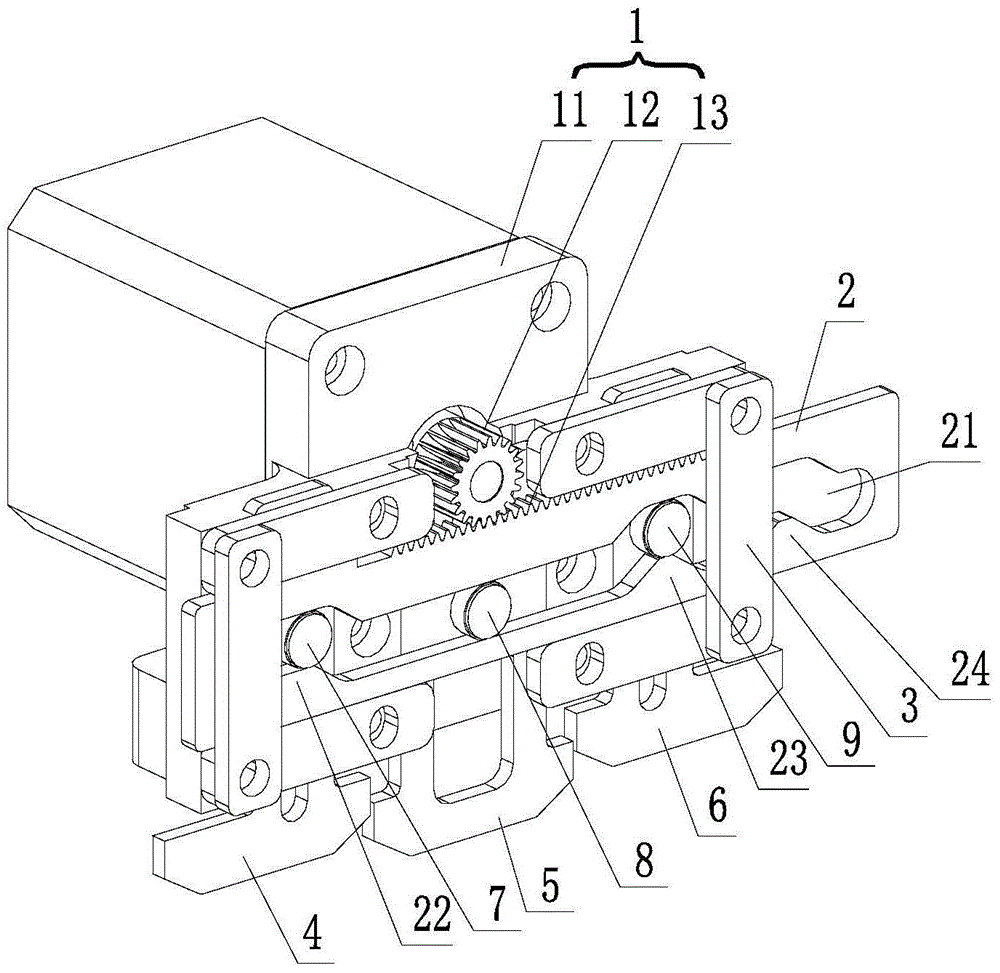

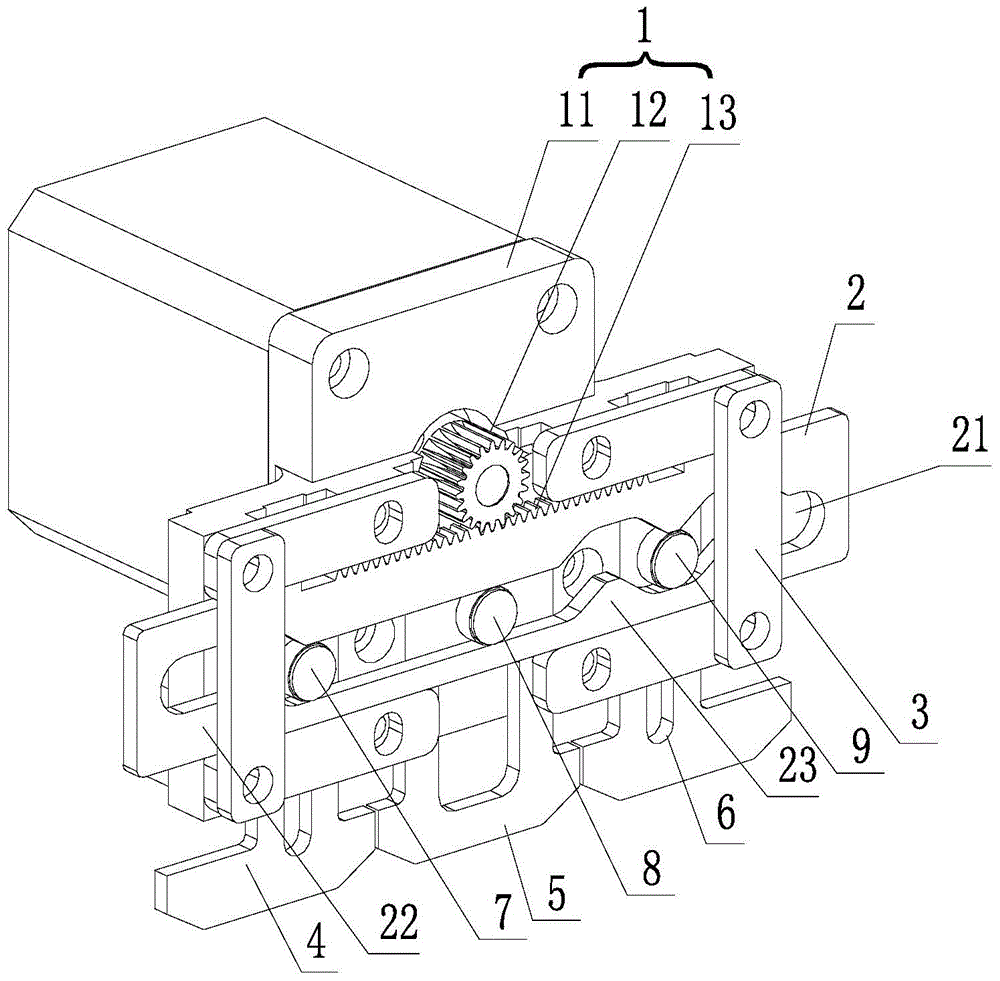

[0018] refer to Figure 1 to Figure 7 , a transmission device for computerized flat knitting machine tucking needle pressing legs, comprising a driving device 1, a movable plate 2, a fixed seat 3, a left needle pressing leg 4, a tucking pressing leg 5, a right needle pressing leg 6, a left The block 7, the middle block 8 and the right block 9; the movable plate 2 is connected with the driving device 1; the fixed seat 3 is provided with a transverse track 31 matching the movable plate 2; the fixed seat 3 is from left to Three longitudinal rails 32 are arranged on the right, and the left needle pressing leg 4, the tuck eye pressing leg 5, and the right needle pressing leg 6 are sequentially installed in the three longitudinal rails 32 from left to right; the left clamping block 7, the middle clamping block 8 and the right block 9 are fixedly connected to the upper end of the left needle presser leg 4, the upper end of the tuck presser leg 5 and the upper end of the right needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com