Rotating siphon type closestool

A toilet and siphon technology, applied in the field of sanitary ware, to achieve the effect of increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below through examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given are not intended to limit the content of the present invention.

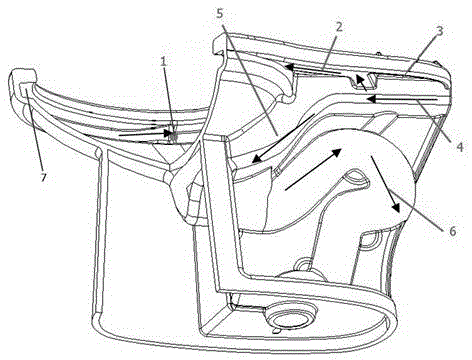

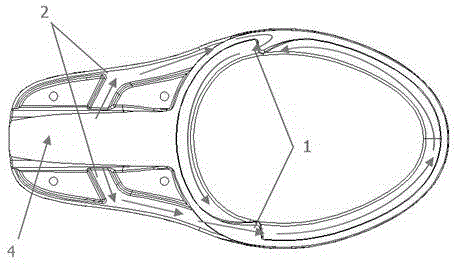

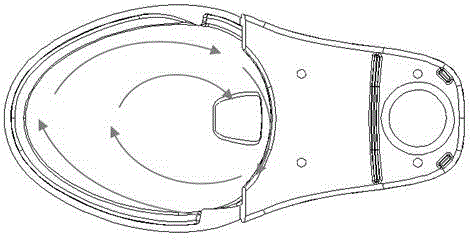

[0017] see figure 1 , figure 2 , the connection between the water tank and the toilet body is provided with a water inlet 3, the main waterway 4 connected to it is arranged below the water inlet 3, and the loop waterway 2 connected with it is respectively arranged on both sides of the main waterway 4, two loop waterways 2 Respectively extend to the annular concave water guide groove 7 provided on the inner edge of the upper mouth of the pot body. The terminal of one circle waterway 2 is provided with the circle surface spray hole 1 facing the front water guide groove 7, and the other end of the circle waterway 2 is provided with The spray holes 1 on the circle surface of the water guiding groove 7 at the rear, and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com