Under-pressure self-moving excavation and support unit and under-pressure self-moving method

A self-moving technology for excavation unit, applied in the direction of cutting machinery, earthwork drilling, cutting machinery, etc., can solve the problems of low efficiency, safety, and hidden dangers, so as to save equipment costs, increase the speed of roadway formation, reduce the The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. This embodiment is only used to further illustrate the present invention, and does not limit the protection scope of the present invention.

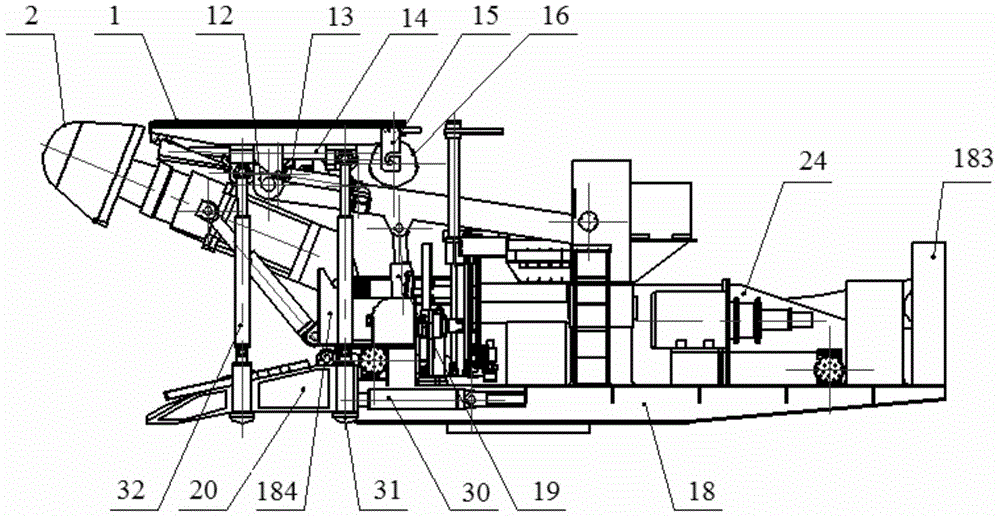

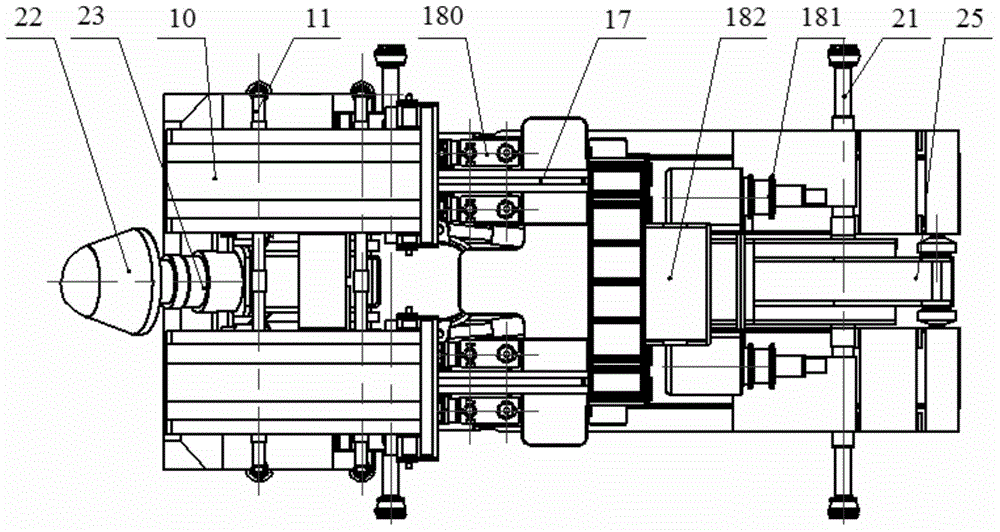

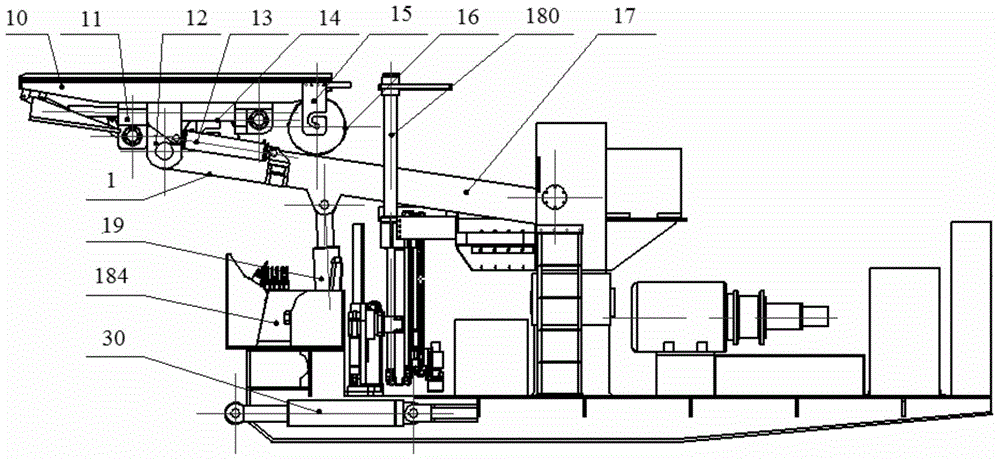

[0042] The embodiment of the present invention relates to a pressurized self-moving excavation unit for coal mine roadway, its structure is as follows Figure 1-10 As shown, it includes: support part 1, excavation part 2 and connecting part. The support part 1 and the excavation part 2 are connected by a connecting part.

[0043]The support part 1 includes a top beam 10, a front support cylinder fixing frame 11, a cross slider 12, a pressurized push cylinder 13, a guide column 14, a metal mesh fixing frame 15, a net roll 16, a support beam 17, a base 18, and a column 19 .

[0044] The excavation part 2 includes a shovel 20 , a cutting and stabilizing oil cylinder 21 , a nozzle 22 , a cutting part 23 , front and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com