Hydraulic five-arm anchor drill for coal mine

A bolt drilling rig and hydraulic technology, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve problems such as low support efficiency, achieve high support efficiency, reduce wind resistance, and be widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

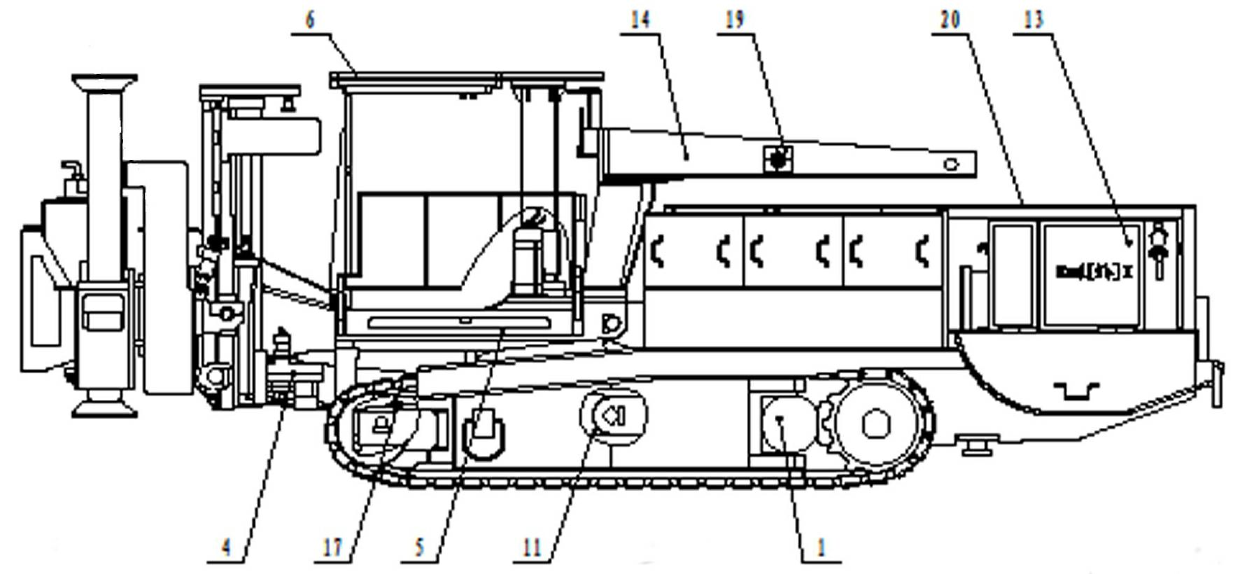

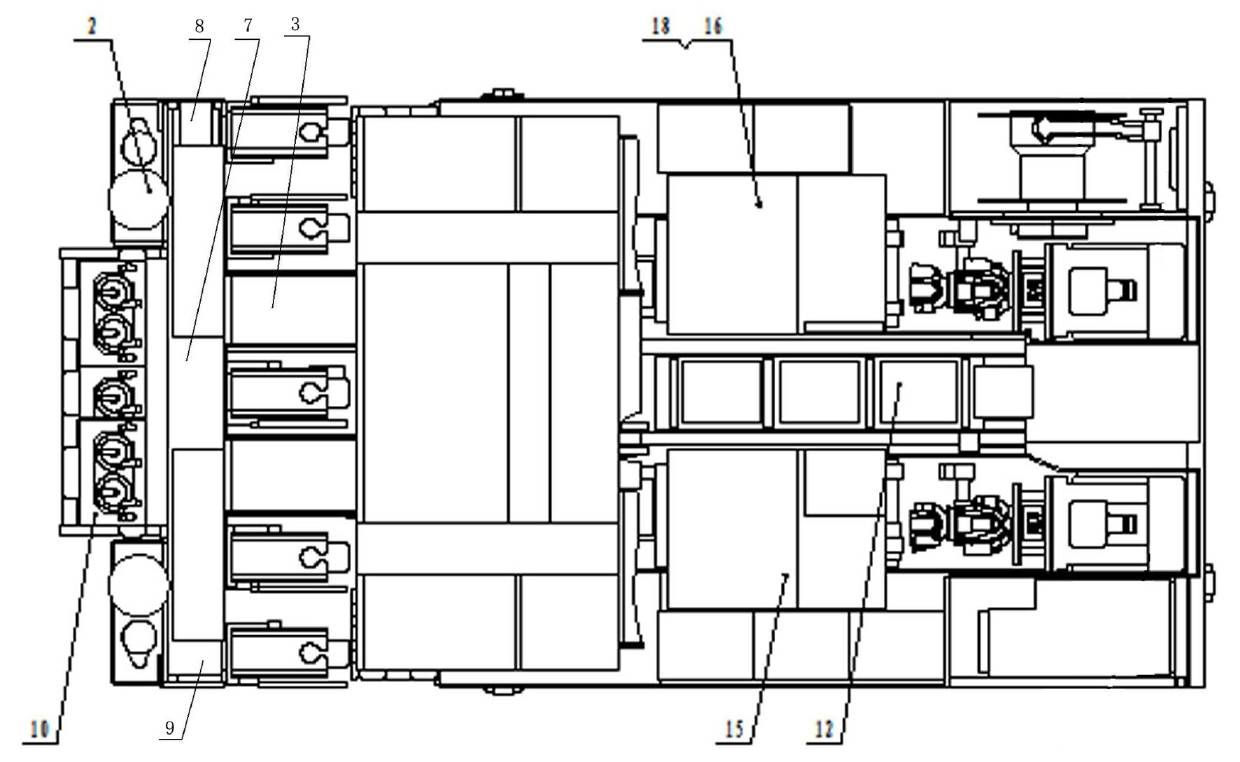

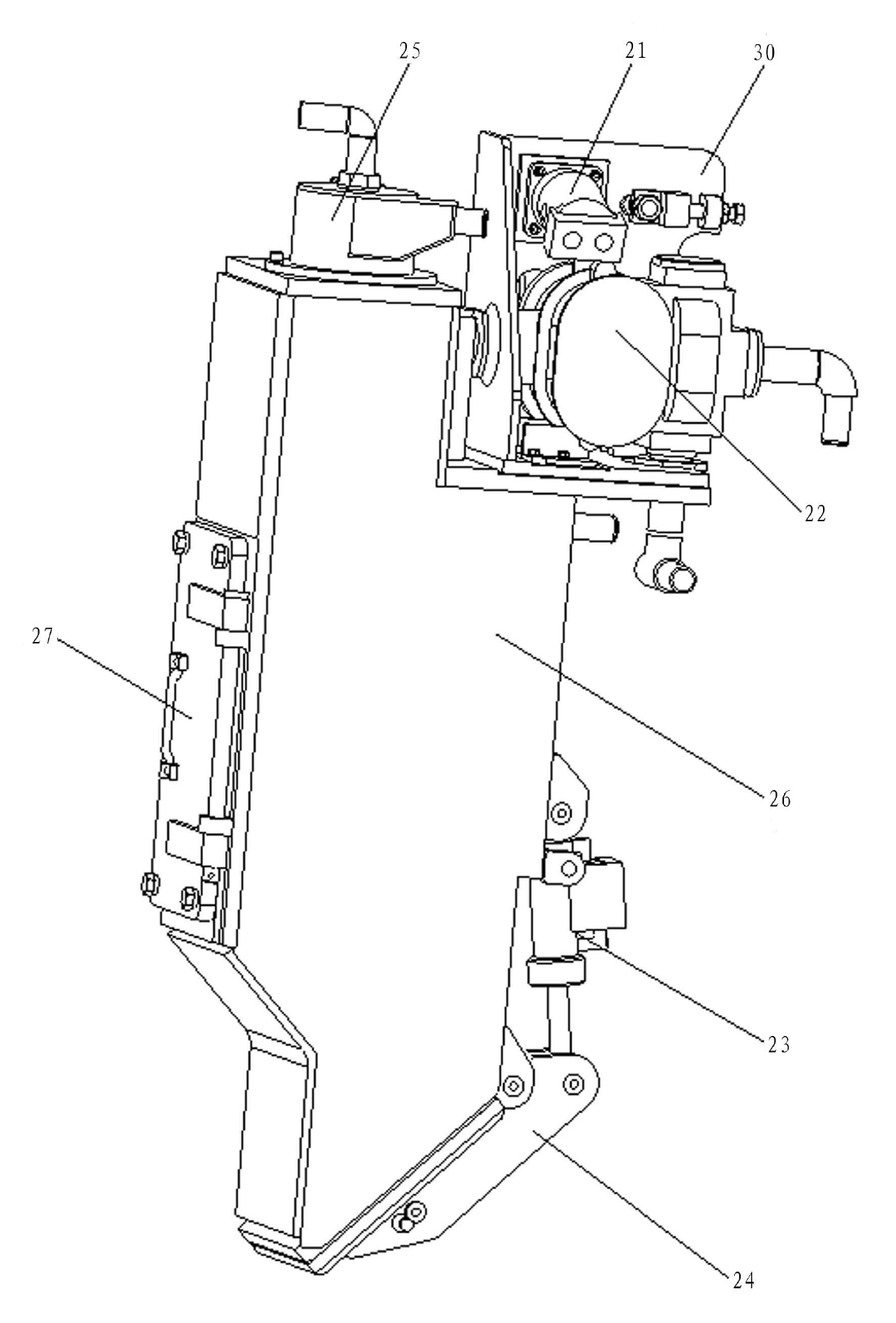

[0021] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0022] Hydraulic rock bolter for coal mine is mainly composed of frame, workbench, temporary support, ceiling, connecting rod mechanism, slide rail, coiled cable, hydraulic system, electrical system, anchor drilling system, dust removal system, etc. Its main technical parameters are as follows:

[0023] Adapt to roadway height (mm): 3200~5100;

[0024] Adapt to roadway width (mm): 5000~5500;

[0025] Maximum mobilization speed (m / min): 25;

[0026] Rock hardness: f≤7 comprehensive rock formation;

[0027] Adapt to the inclination angle of the roadway (°): ≤16°;

[0028] Minimum ground clearance (mm): 300mm;

[0029] Installed power (kW): 2×55;

[0030] Number of drill arms: 5;

[0031] Maximum drilling depth (mm): 2600;

[0032] Grid voltage level (V): 1140 / 660.

[0033] 1. Arrangement of five drill arms.

[0034] Five drilling arms are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com