A diesel engine post-processing scr control device and control method

A diesel engine and control device technology, applied to the electronic control of exhaust treatment devices, engine components, combustion engines, etc., can solve the problems of CAN network data exchange security risks, no low power consumption design, no power management system, etc. Achieve the effect of improving the accuracy and stability of system signal acquisition, improving system reliability and security, and improving system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0073] The present invention will be described in detail below with reference to the accompanying drawings and examples.

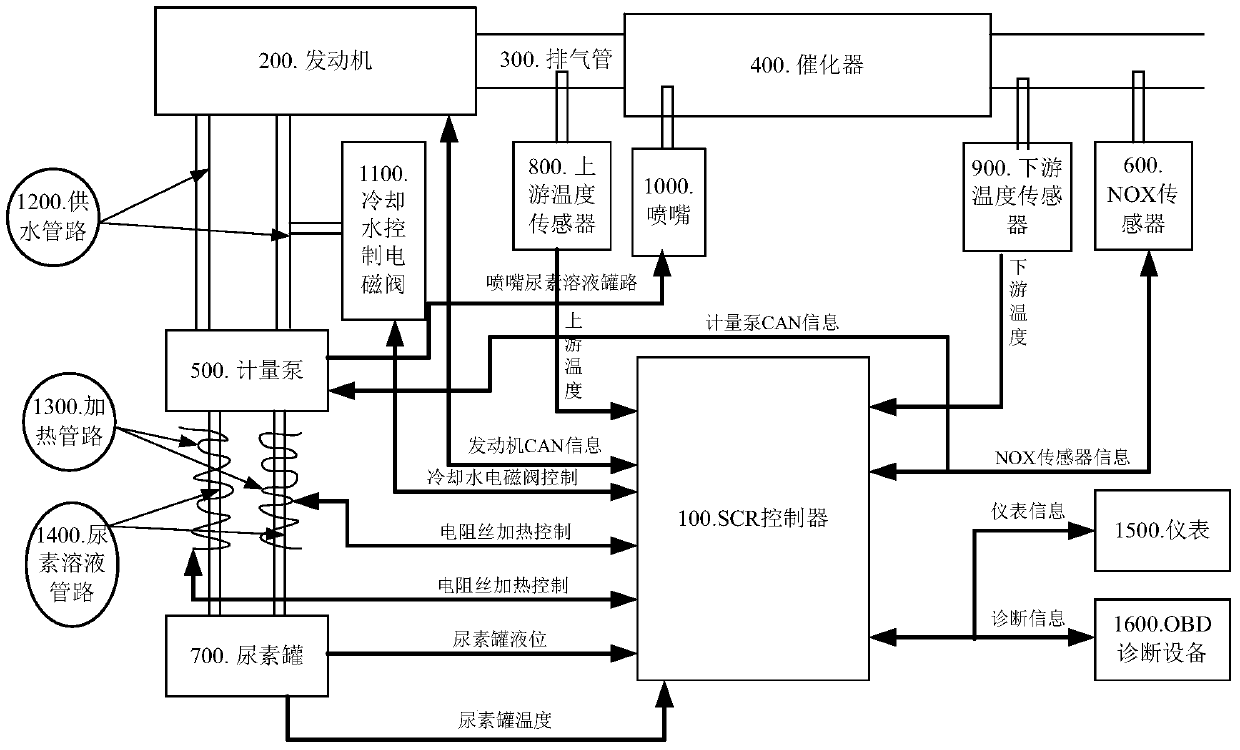

[0074] figure 1 It is the overall structural block diagram of the control system of the present invention, including SCR controller 100, engine 200, exhaust pipe 300, catalytic converter 400, metering pump 500, NO X Sensor 600, urea tank 700, upstream temperature sensor 800, downstream temperature sensor 900, nozzle 1000, cooling water control solenoid valve 1100, water supply pipeline 1200, heating pipeline 1300, urea solution pipeline 1400, instrument 1500, OBD diagnostic equipment 1600 .

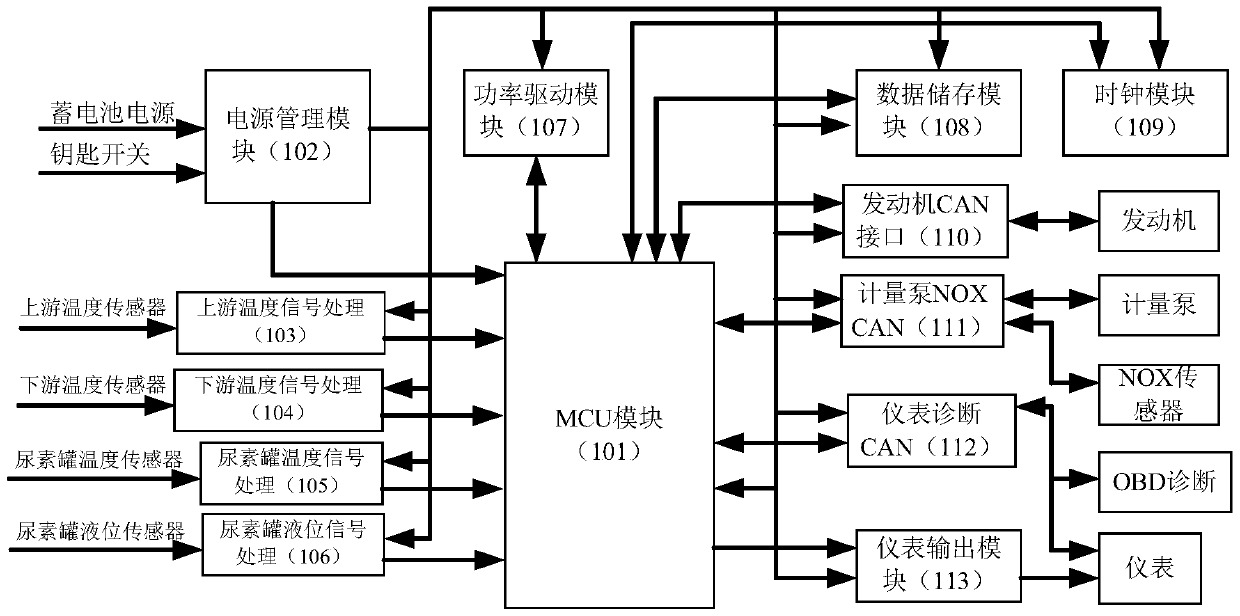

[0075] figure 2 It is a hardware block diagram of the SCR controller 100 of the control system of the present invention. The SCR controller 100 includes an MCU module 101, a power management mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com