LED light source drive board

A technology of LED light source and driver board, which is applied in the field of lighting, can solve the problems of rising labor costs, low pass rate, cumbersome process, etc., and achieve the effects of facilitating automated production, improving production efficiency, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below through specific embodiments:

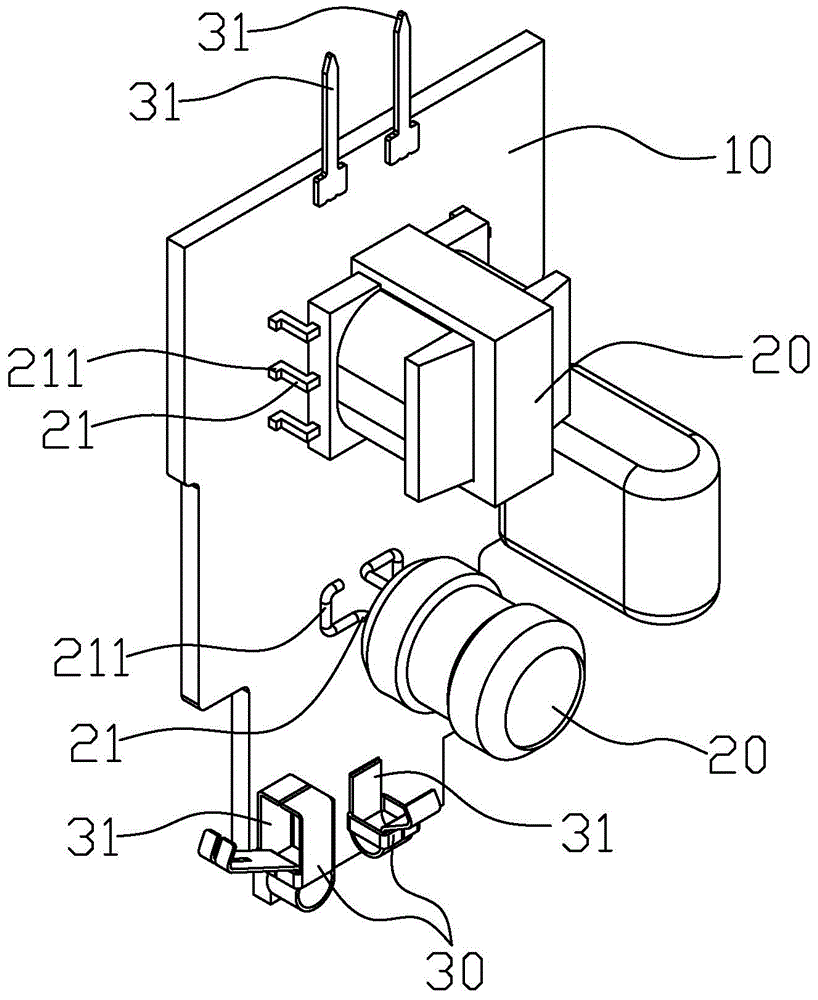

[0011] figure 1 It is a perspective view of the LED light source driving board of the first embodiment of the present invention. The LED light source driving board 10 is used to supply power to the LED light source board. At least one electronic component 20 is provided on one side of the LED light source driving board 10. At least one electrical connection terminal 30 is also provided on the board 10. Preferably, the electronic components 20 and the electrical connection terminals 30 are all arranged on one side of the LED light source driving board 10.

[0012] Please refer to figure 1 At least two electrode pins 21 are provided on these electronic components 20, and the ends of these electrode pins 21 are all bent to form a supporting section 211. All the supporting sections 211 of all the electrode pins 21 are located on a plane so that these The electronic components 20 can be pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com