A Fairing Method for Asymmetric Ship Shape

An asymmetric and smoothing technology, which is applied in the field of ships, can solve the problems of disordered data arrangement, inability to directly smooth, not in the middle and vertical plane, etc., to achieve simple line type, shorten the smoothing period, and reduce the difficulty of smoothing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

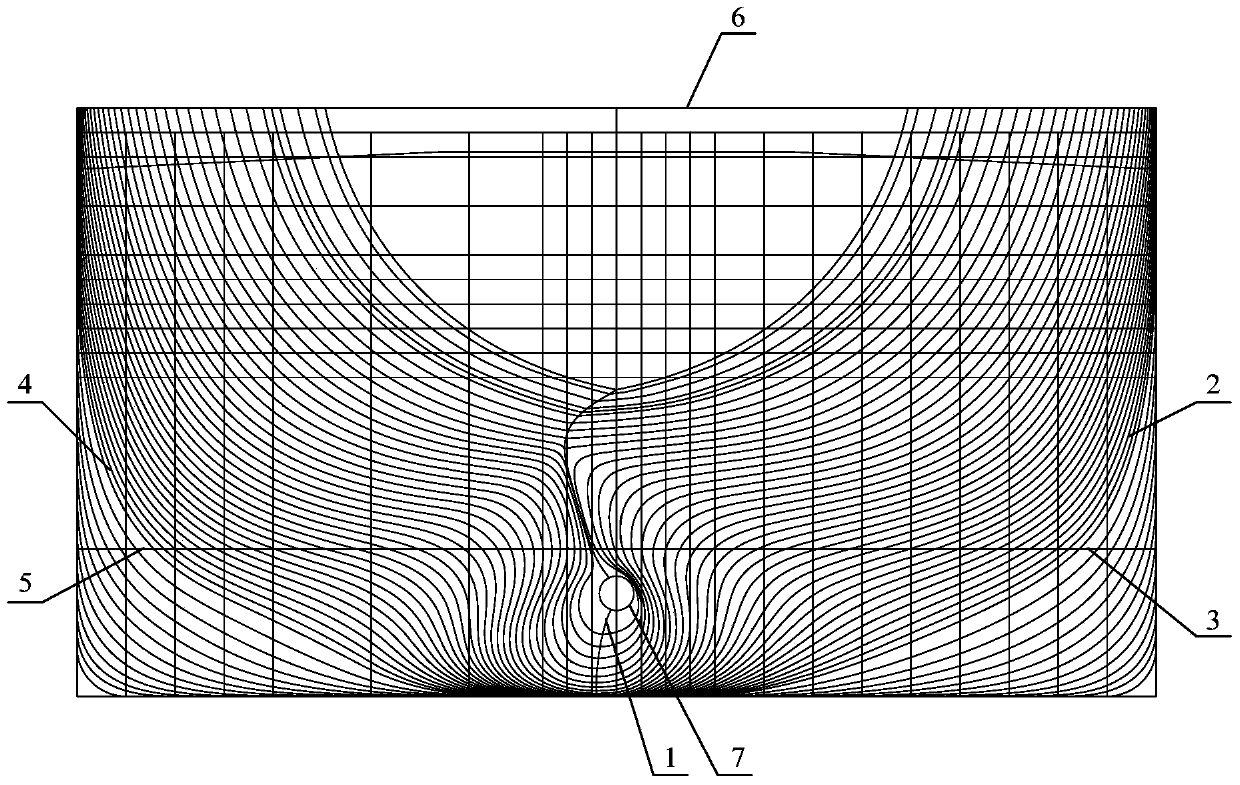

[0023] figure 1 It is the profile diagram of the asymmetric ship type provided by the specific embodiment of the present invention.

[0024] In the present invention, the Pline line is a three-dimensional curve used for smoothing the hull shape; the whole ship Patch is the grid unit forming the hull surface; Surface refers to the digitalized hull surface data package.

[0025] A smoothing method for an asymmetric ship shape, the asymmetric ship has an asymmetric stern, and the line shape of the stern outline is distorted, the steps are as follows,

[0026] Step 1, divide the hull of the asymmetric ship into a plurality of regions, preferably, divide the hull of the asymmetric ship into a bow and a stern at the midship, the bow is divided into a first bow and a second bow, the first bow a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com