Rack guide for rack and pinion steering, method for manufacturing rack and pinion steering, and rack guide for rack and pinion steering

The technology of a rack guide and a steering device is applied in the manufacturing field of a rack guide for a rack-and-pinion steering device, a rack-and-pinion steering device, and a rack guide for a rack-and-pinion steering device. It is difficult to simplify the manufacturing process of the rack guide, etc., to achieve the effect of simplifying the shape, realizing the tightness, and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

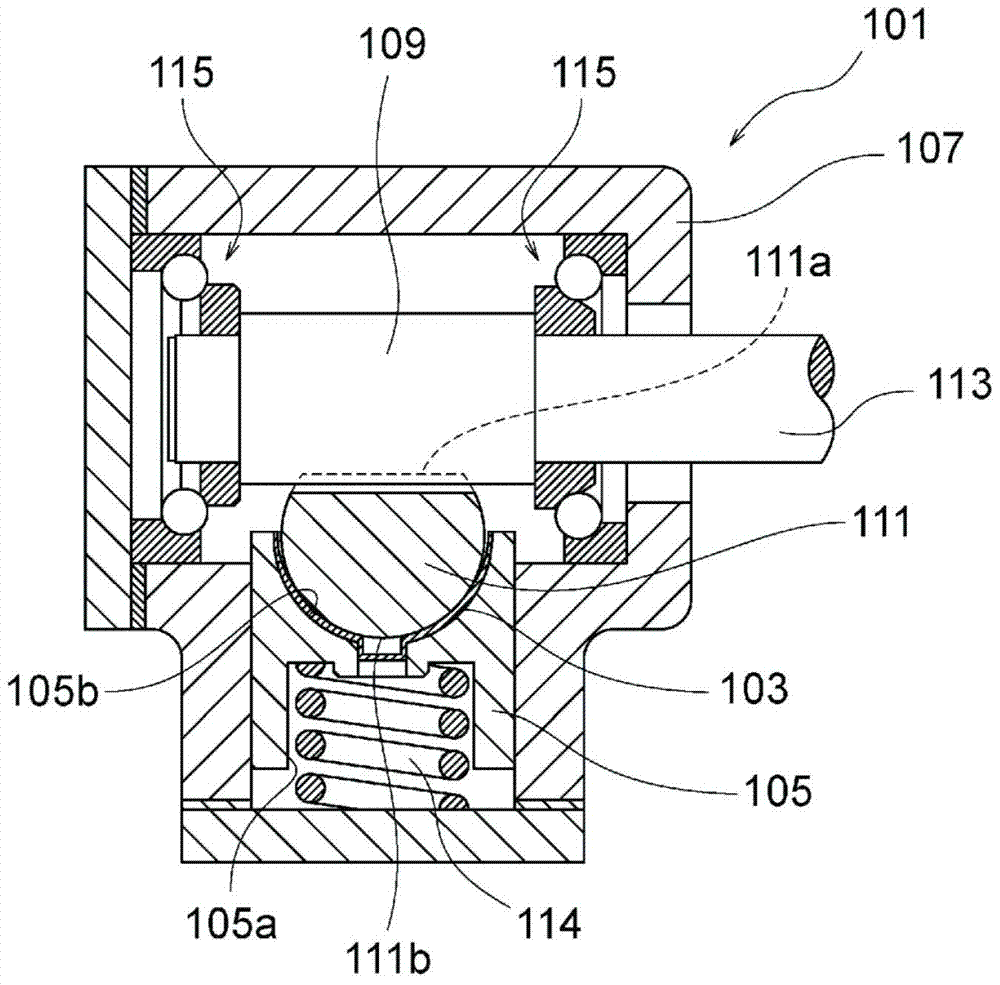

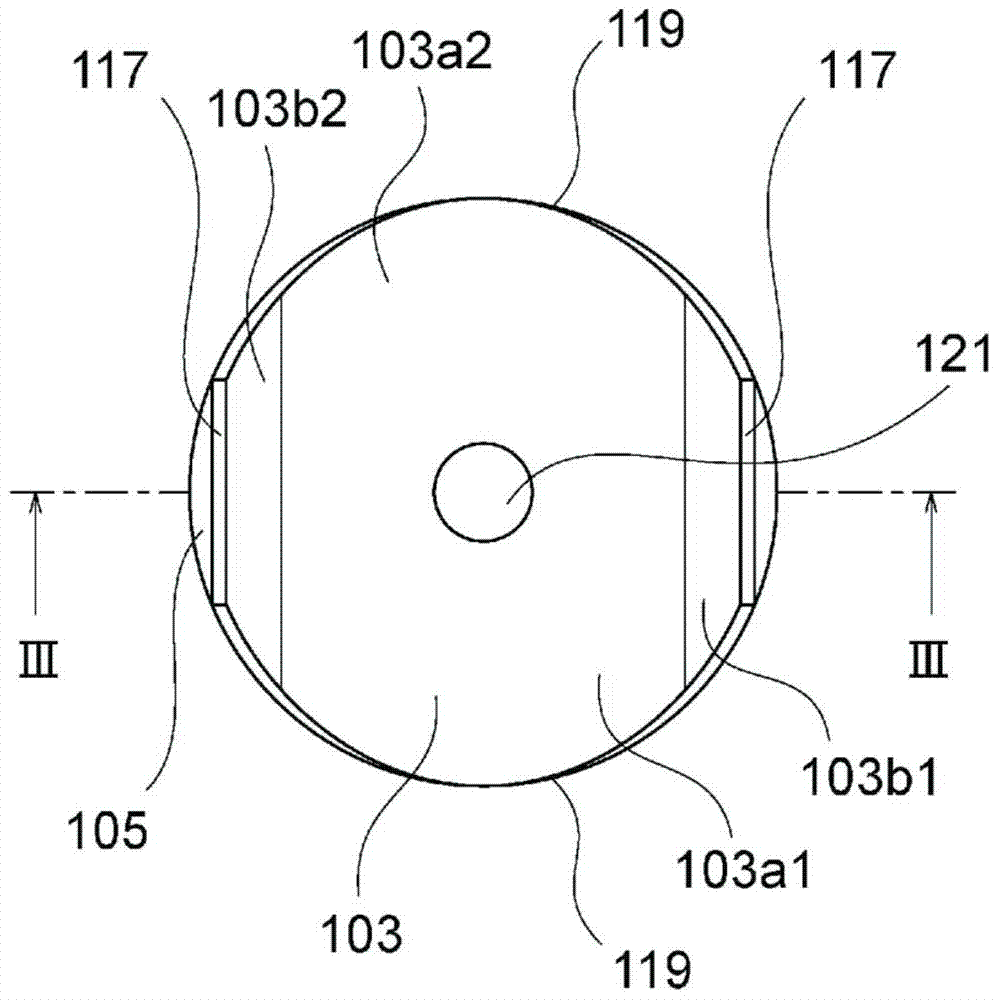

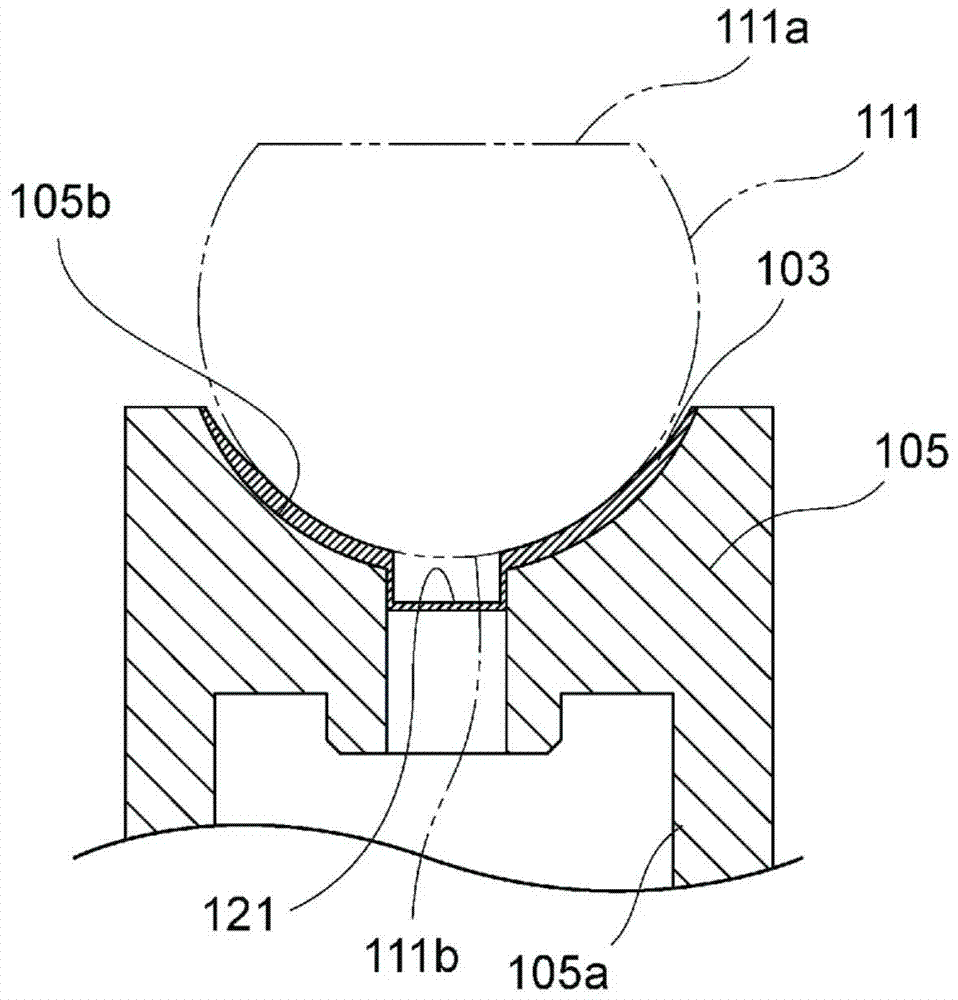

[0033] figure 1 is a longitudinal sectional view schematically showing a part of the rack and pinion steering device 101 of the first embodiment, figure 2 yes figure 1 A top view of the rack guide 103 and the rack guide base 105 is shown, image 3 is along figure 2 The sectional view of the line III-III (the diameter of the rack guide base 105), Figure 4 will be figure 1 An enlarged cross-sectional view showing an enlarged representation of the rack guide 103, Figure 5 yes Figure 4 An enlarged cross-sectional view of the V portion of . in addition, figure 1 , Figure 4 , Figure 6 and image 3 Similarly, it is a sectional view of a virtual plane bisecting a linear edge portion 117 described later along a center line x passing through the rack guide 103 , the rack guide base 105 , and the fixing portion 121 concentric with each other in plan view.

[0034] Such as figure 1As shown, the rack and pinion steering device 101 mainly includes: a casing 107 as a box; ...

no. 2 approach

[0056] Figure 7 adopt and image 3 The same section shows a sectional view of the rack guide 303 and the rack guide base 305 constituting the rack and pinion steering device of the second embodiment. Unlike the rack guide 103 of the first embodiment, the rack guide 303 of the second embodiment has a so-called Y shape, and the outer surface Q2 of the rack tie rod 311 abutting on the rack guide 303 is formed of an inclined surface. Note that, except for the rack guide 303 and the rack guide base 305 , the elements constituting the rack and pinion steering device are all conventionally known structures, and thus detailed description thereof will be omitted.

[0057] Such as Figure 7 As shown, the rack rod 311 is equipped with a gear (refer to figure 1 The reference numeral 109) engages the rack teeth 311a. The rack guide 303 has abutment portions 303a1, 303a2 that slidably abut against the rack rod 311, and exit portions 303b1, 303b2 connected to one ends of the abutment po...

no. 3 approach

[0069] refer to Figure 8 The rack guide 403 of the third embodiment will be described. Figure 8 It is a cross-sectional view of the rack guide 403 of the third embodiment. In addition, the cross-sectional view and image 3 Similarly, the rack guide 103 of the first embodiment shown is a cross-sectional view of an imaginary plane along the center line x passing through the fixed portion 421 and bisecting the linear edge portion 417 . In addition, the rack guide 403 is a modified example in which the positions of the abutting portion and the retreating portion of the rack guide 103 of the first embodiment are changed, and may be assembled in place of the rack guide 103 . figure 1 On the rack and pinion steering device 101 shown. Therefore, appropriate reference Figure 1 to Figure 4 . In addition, the structure, effect, etc. which are not specifically described in the rack guide 403 are the same as those of the rack guide 103 of 1st Embodiment.

[0070] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com