Spherical drum type stir-frying machine

A drum frying-drier, spherical technology, applied in the direction of tea processing before extraction, can solve the problems of dark color, unable to achieve the effect of throwing, and unable to discharge moisture in time, and achieve the effect of emerald green color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the present invention, the following describes the solutions in the embodiments of the present invention clearly and completely with reference to the accompanying drawings in the embodiments of the present invention.

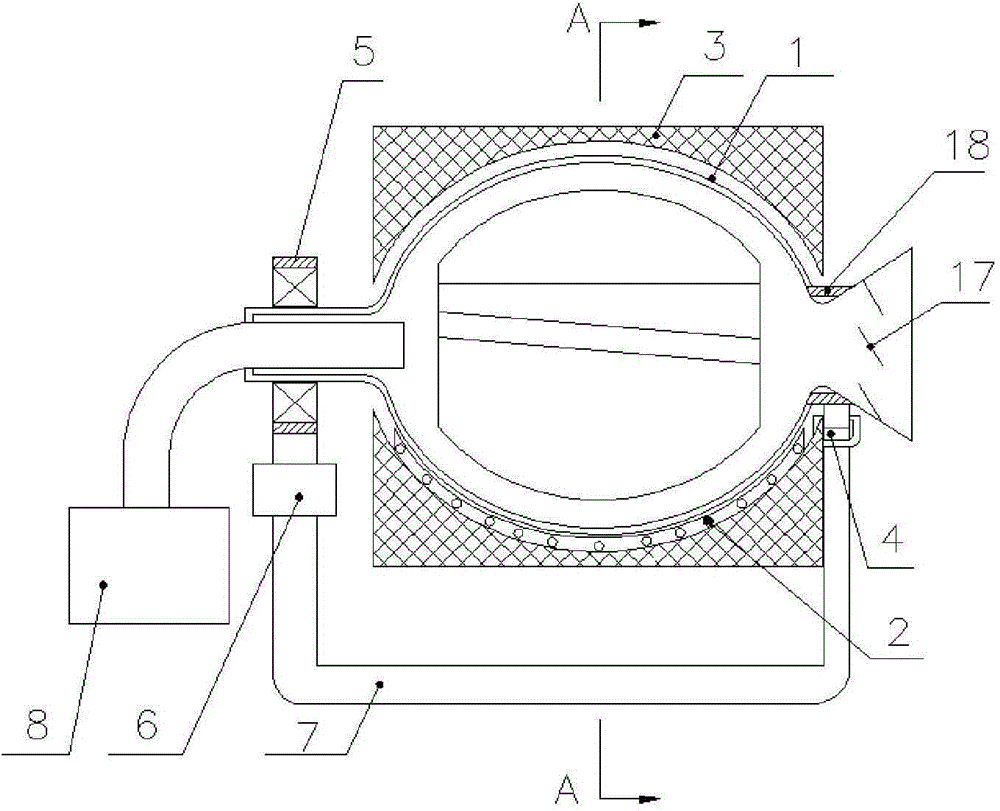

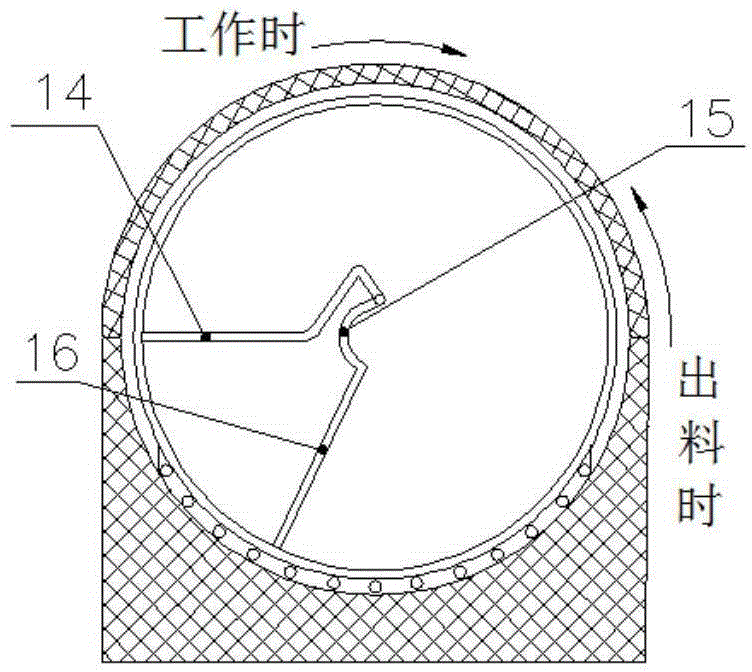

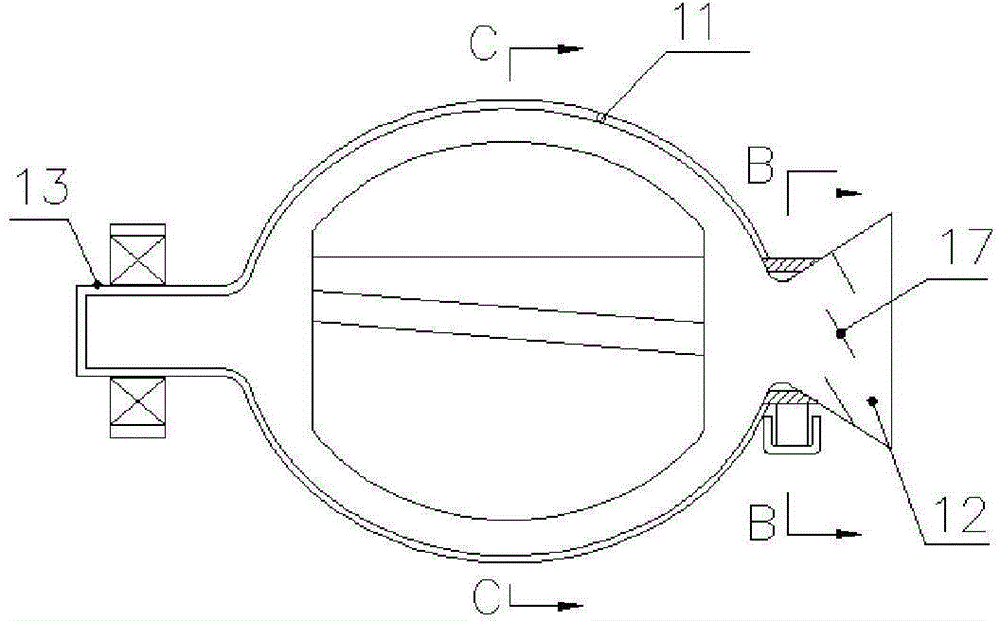

[0018] See Figure 1 to Figure 5 .

[0019] The spherical drum roasting and drying machine according to the embodiment of the present invention includes a spherical drum 1, a heating device 2, a heat preservation cover 3, a supporting wheel device 4, a bearing seat 5, a transmission reduction device 6, and a bracket 7. The left and right ends of the spherical drum 1 are respectively provided with bearings The seat 5 and the supporting wheel device 4 are supported and placed on the bracket 7, the transmission reduction device 6 is located on the side of the bracket 7 close to the bearing seat 5, and the transmission reduction device 6 drives the spherical roller 1 to rotate on the bracket 7 for alignment The heating device 2 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com