A kind of 3D printer with multi-nozzle and printing method thereof

A 3D printer and multi-nozzle technology, applied in the field of 3D printing, can solve the problems of printing model gaps, nozzle printing interference, insufficient material extrusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

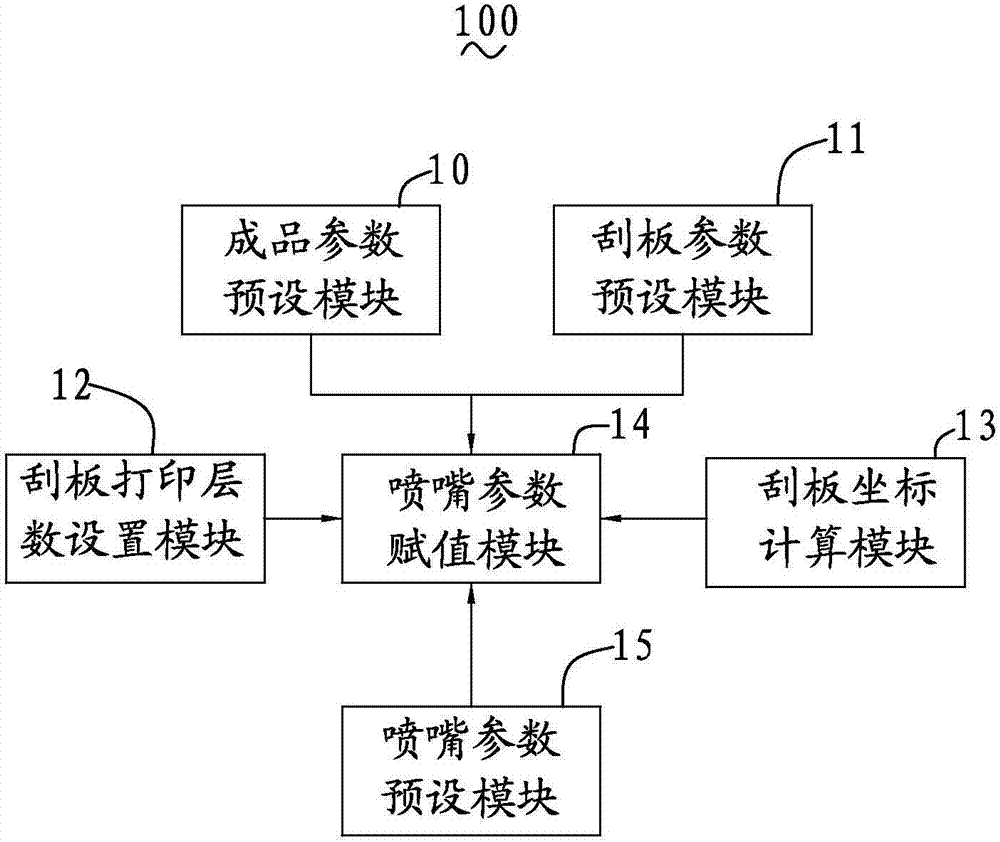

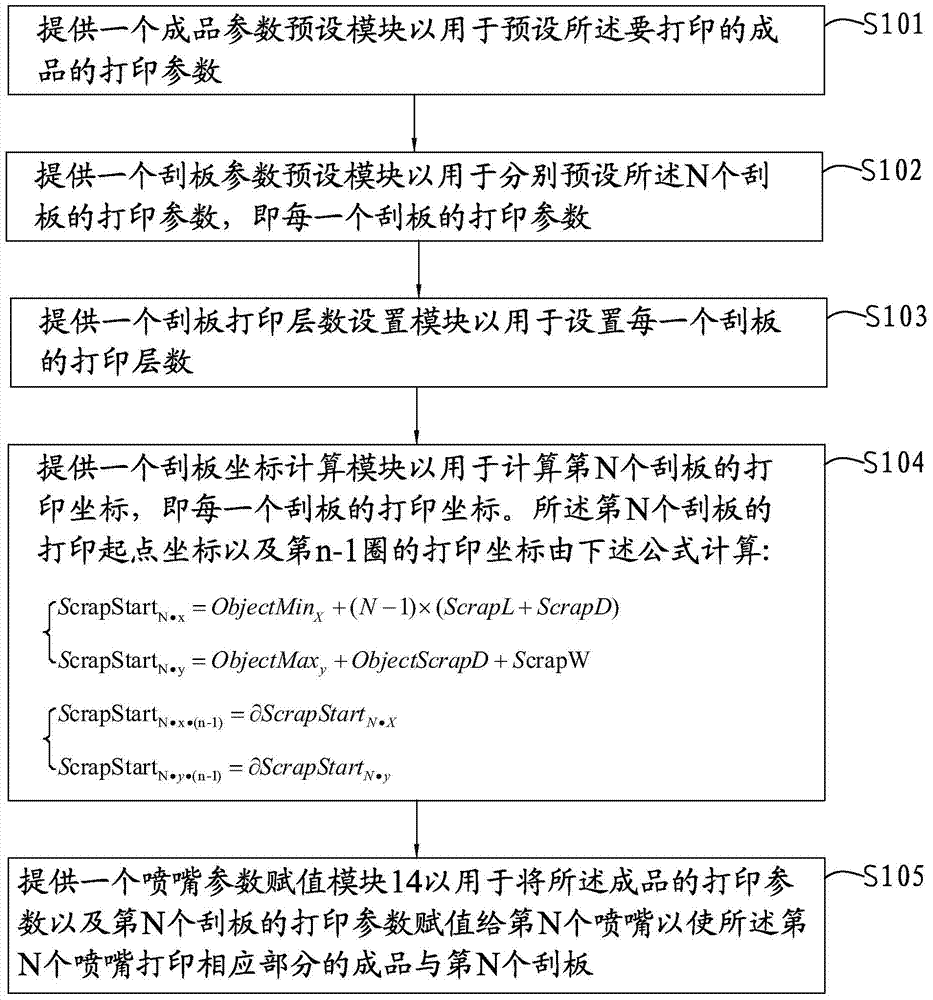

[0059] Such as figure 1 As shown, it is a functional block diagram of a 3D printer 100 with multiple nozzles provided by the present invention. The 3D printer with multiple nozzles 100 has N nozzles, where N≥2, for printing products made of multiple materials in the same manufacturing process. In this embodiment, the 3D printer as hardware and its multiple nozzles are not shown in the figure, which is a prior art known to those skilled in the art. At the same time, the computer hardware inside the 3D printer, such as the central processing unit, memory, input and output interfaces, instruction execution hardware or software, and program execution hardware or software, are all conventional equipment that any 3D printer has, and are all of this It is well known to those skilled in the art, and no special description is required in this embodiment.

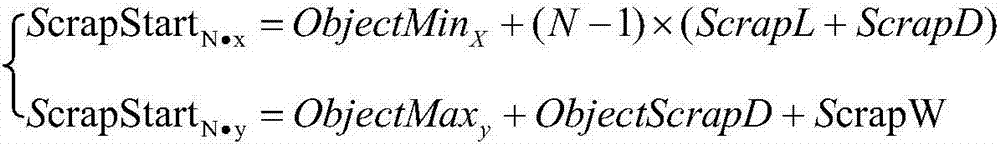

[0060] It should be noted that the product printed by the multi-nozzle 3D printer 100 includes a finished product and N scrapers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com