Printing slotting die-cutting machine with a spiral lifting adjustment apparatus in the printing portion

A technology of screw lifting and adjusting device, applied in packaging, transportation and packaging, container manufacturing machinery and other directions, can solve problems such as affecting the quality of carton prints, deviation of the height of suction and feeding cartons, and inability to meet market requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

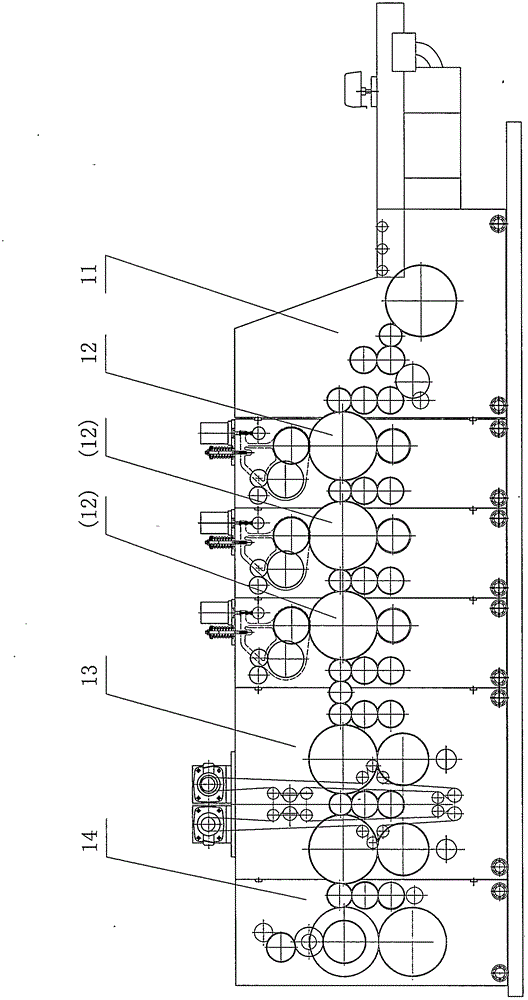

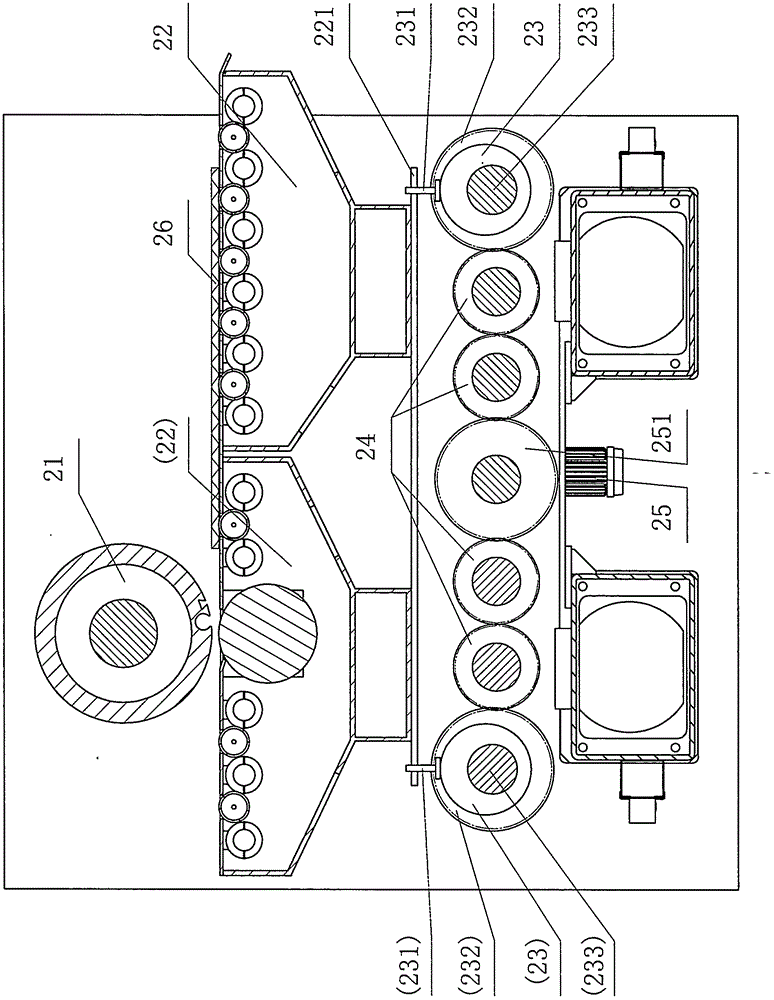

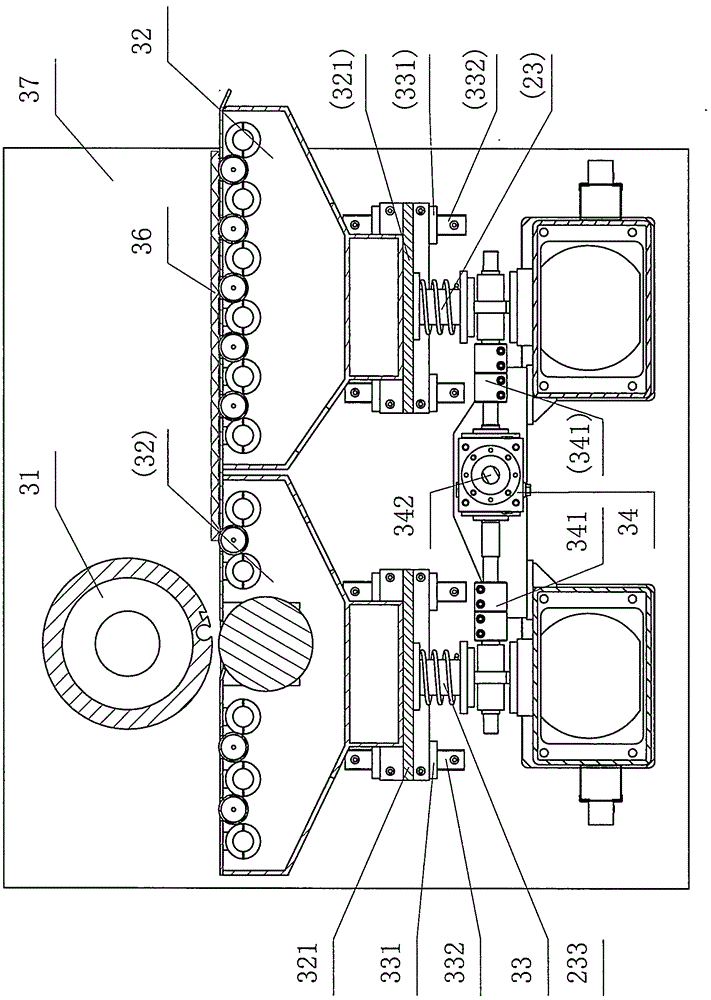

[0010] The main structure of the printing slotting die-cutting machine with the spiral lifting adjustment device in the printing part of the present invention is as follows: figure 1 As shown, it mainly includes paper feeding unit, multiple printing units, slotting unit and die-cutting unit. The printing part is equipped with a spiral lifting adjustment device, the main structure is as follows: image 3 , Figure 4 As shown, between the two wallboards 37 and 38 of the printing section of the printing slotting die-cutting machine, two groups of air-suction cartons 32 are installed, and a liner 321 is respectively fixed at both ends of the bottom of each group of air-suction cartons. The liner is fixedly connected with the sliders 321 mounted on the two movable slides inside the wallboard. Under each liner 321, there is a screw lifter 33 on the top. The two screw lifters 33 in the horizontal direction pass through the coupling. 341 is connected with a T-type coupling 34, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com