Electromagnetic chuck lifting mechanism for section steel stacker crane and control method thereof

A technology of electromagnetic chuck and lifting mechanism, which is applied in the field of palletizing, can solve the problems of high manufacturing cost, poor synchronization performance, cumbersome installation and maintenance, etc., and achieve the effect of low manufacturing cost, high synchronization and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

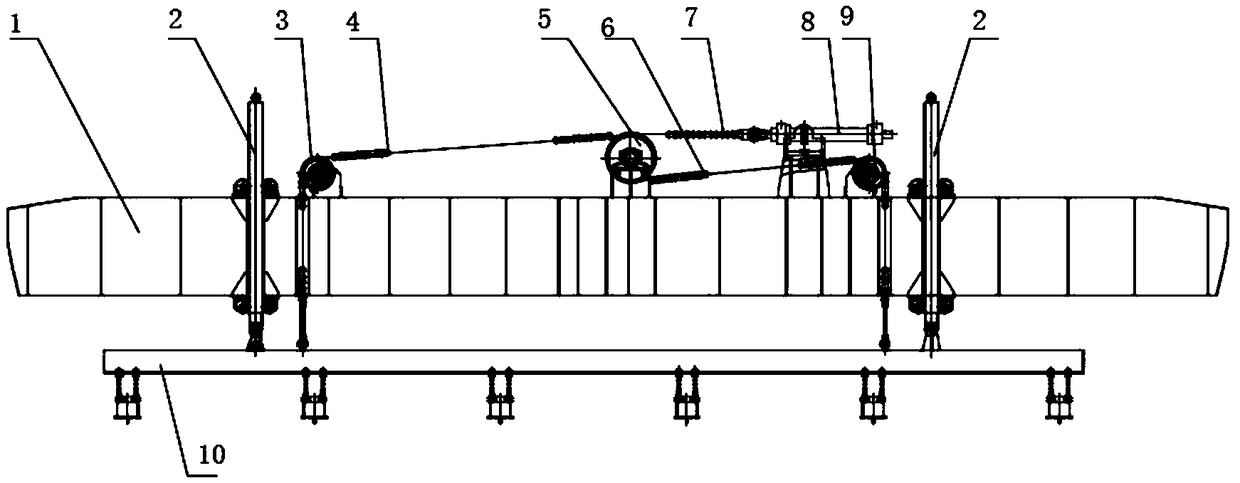

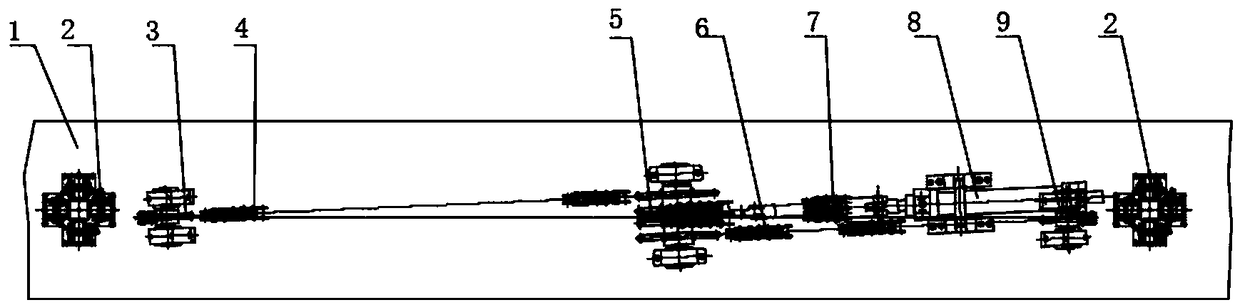

[0045] Such as figure 1 and figure 2 As shown, an electromagnetic sucker lifting mechanism for a section steel palletizer includes a beam 1, the beam 1 is a welded workpiece, the welding process is simple and the joint strength is high, so that the beam 1 has high strength; the upper and lower ends of the beam 1 There are several supports between them, including the left steering sprocket 3, the left chain 4, the synchronous sprocket 5, the right chain 6, the drive chain 7, the oil cylinder 8, the right steering sprocket 9 and the electromagnetic chuck device 10 , the left steering sprocket 3, the synchronous sprocket 5, the oil cylinder 8 and the right steering sprocket 9 are sequentially fixed on the support between the upper and lower end faces of the beam 1 through a fastening device. Preferably, the fastening device For fastening bolts or fastening screws, the structure is simple, the stability is good, and the cost is low; other fastening devices known to the public ca...

Embodiment 2

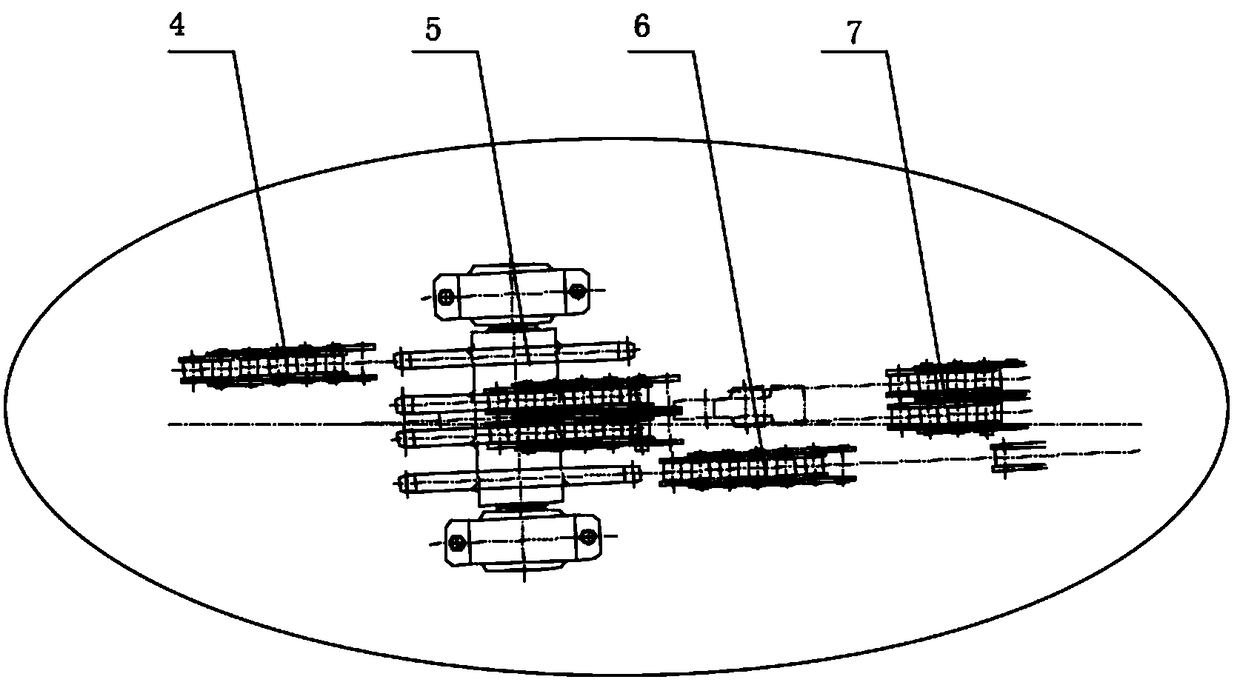

[0050] Basically the same as embodiment 1, such as Figure 5 and Figure 6 As shown, this embodiment also includes a guide device 2, the installation position of the guide device 2 on both sides of the beam 1 is provided with a through guide hole, the guide device 2 passes through the guide hole and is arranged symmetrically along the center of the beam 1, and the setting of two guide devices 2 is effective It avoids the shaking of the electromagnetic chuck device 10 during the lifting process, and ensures that the section steel has good stability during the lifting process; the guide device 2 includes a guide rod 21 and several guide wheels 22; preferably, the guide wheels 22 are Eight, eight guide wheels 22 are divided into two groups, and each group of four guide wheels 22 is symmetrically distributed in a "ten" shape, and each group of guide wheels 22 is connected with the support on the beam 1 through a fastening device. The device is a fastening bolt or a fastening scre...

Embodiment 3

[0052] Basically the same as embodiment 1, preferably, one end of the left chain 4 and one end of the right chain 6 are provided with a fork with a stud adjustment device, and the fork and the connecting beam 101 in the electromagnetic chuck device 10 pass through the pin Connection, the other end of the left chain 4 and the other end of the right chain 6 are connected to the synchronous sprocket 5 through the corresponding pin hole in the synchronous sprocket 5; during the initial assembly or later use, due to the length error or wear of the chain, The connecting beam 101 is tilted and the lifting of the whole device is hindered. At this time, by adjusting the stud adjustment device at the fork of the left chain 4 and the right chain 6, the connecting beam 101 is adjusted to a horizontal posture, and the connecting beam 101 is monitored in real time. The state and timely adjustment, the whole process is easy and timely to operate, so that the safety performance and synchroniza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com