Weight loading device for lift security element detection

A technology of safety components and loading devices, applied in the directions of transportation, packaging, cranes, etc., can solve the problems of low loading efficiency, affecting the test results, difficult to fix, etc., to achieve safety guarantee, reduce manual operations, and improve the effect of loading and unloading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

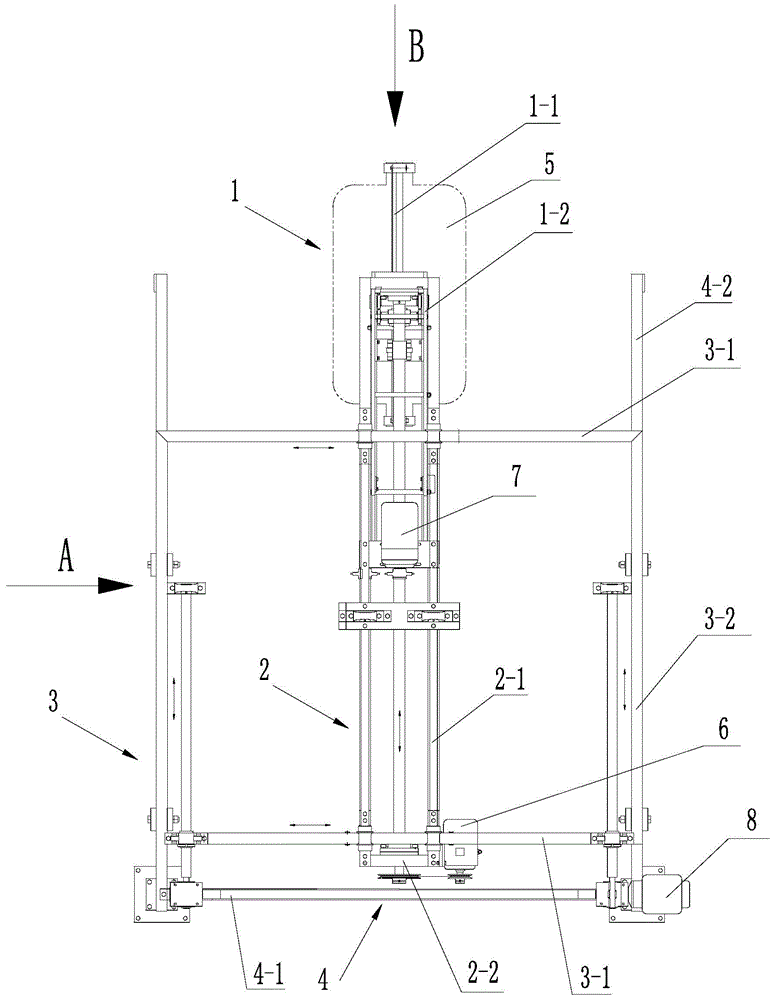

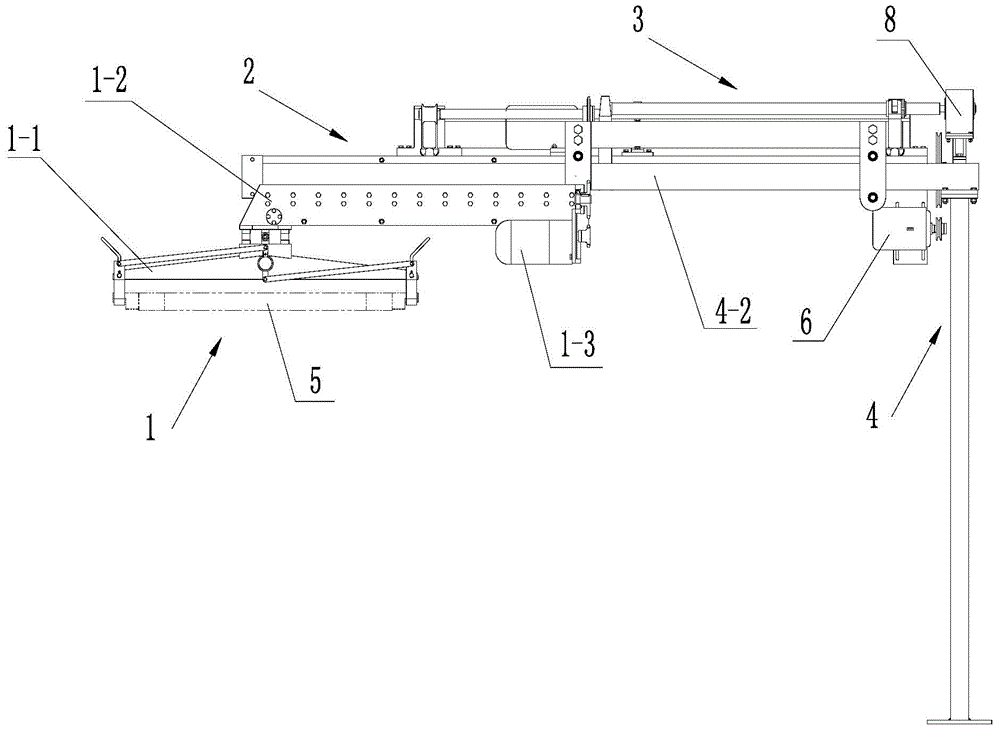

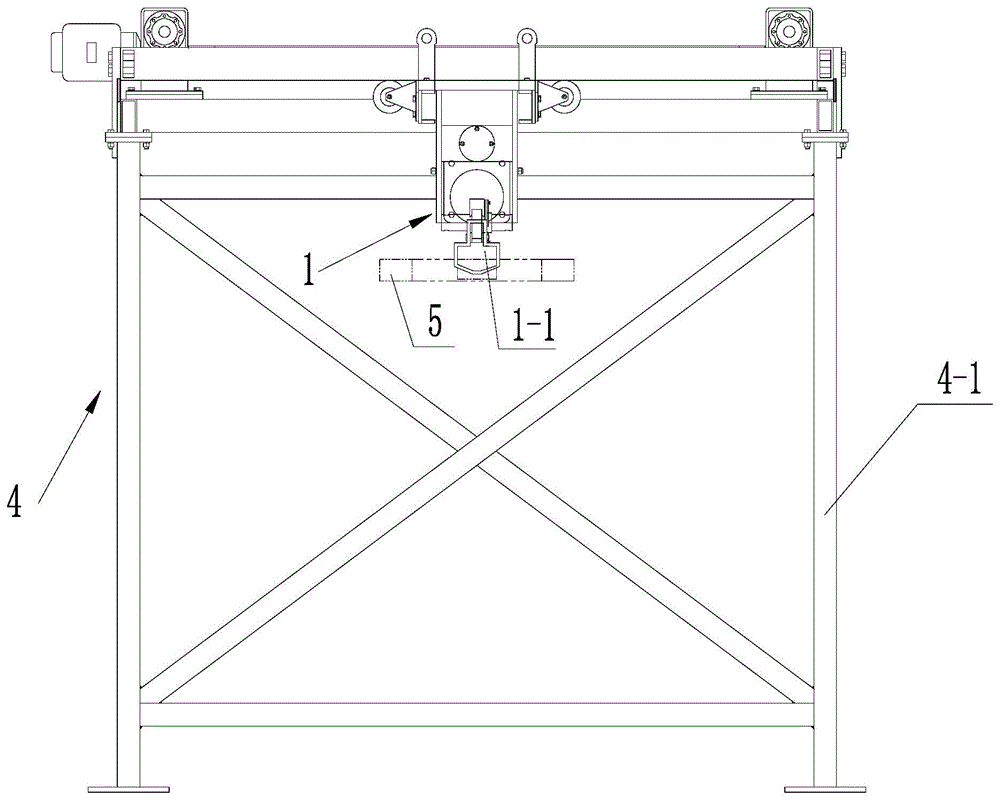

[0026] In this embodiment, a kind of weight loading device used for elevator safety component detection, such as Figure 1~3 As shown, it includes hook lifting mechanism 1, lateral moving frame 2, longitudinal moving frame 3 and bottom frame 4, the hook lifting mechanism is slidingly connected with the bottom of the horizontal moving frame, the top of the horizontal moving frame is slidingly connected with the longitudinal moving frame, and the vertical moving frame The bottom is slidingly connected with the bottom frame; the hook lifting mechanism moves longitudinally along the horizontal moving frame, the horizontal moving frame moves horizontally along the longitudinal moving frame, and the vertical moving frame moves longitudinally along the bottom frame. Among them, the hook lifting mechanism is used to extract and load weights, and the bottom frame is mainly used to fix other components of the weight loading device. The hook lifting mechanism itself can move forward and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com