A kind of server wrapping paper tray

A technology of industrial wrapping paper and server, which is applied in the field of server industrial wrapping paper trays, can solve the problems of increasing the packaging cost of a single server, damage to server products, large shock and vibration, etc., achieves outstanding environmental protection and economical efficiency, and reduces usage , Reduce the effect of shock and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

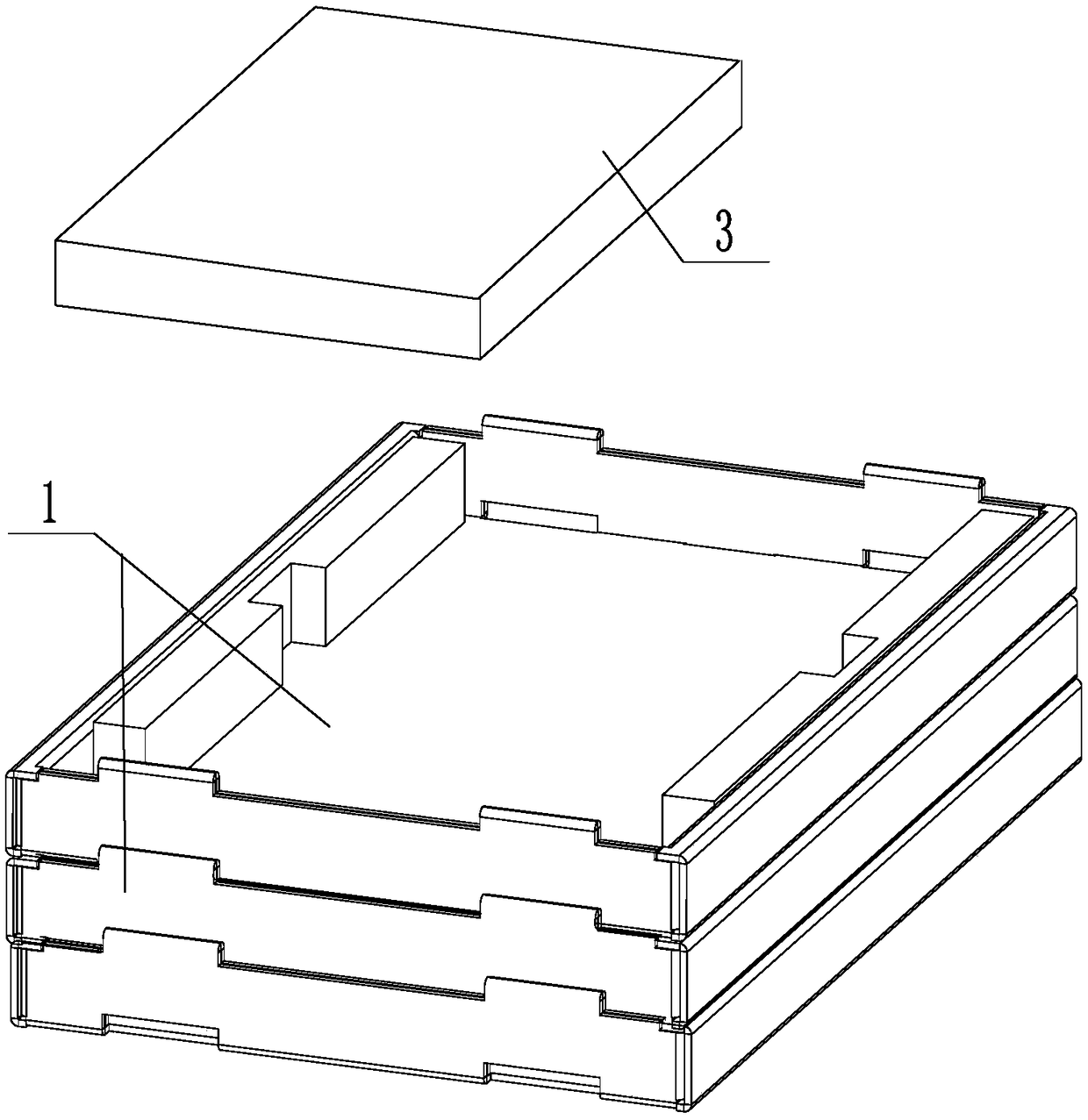

[0027] The server package paper tray is made of double corrugated cardboard. The double corrugated cardboard is die-cut with a die-cutting plate, and then the die-cut double corrugated cardboard is folded to form a shallow plate-shaped work package paper tray. The structure is molded by inserting and locking during the molding process, and does not need to be stapled or glued. It is suitable for mass and rapid production, and it is economical and environmentally friendly.

[0028] The present invention will be further analyzed below in conjunction with accompanying drawing.

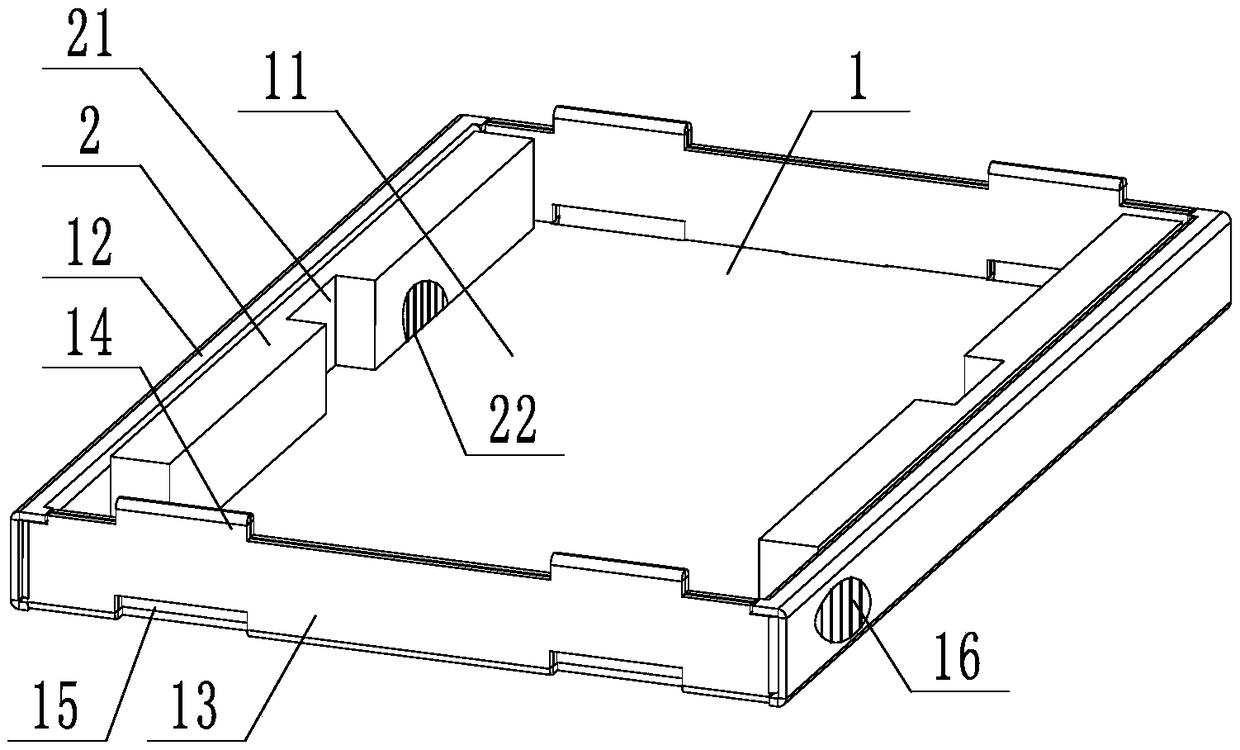

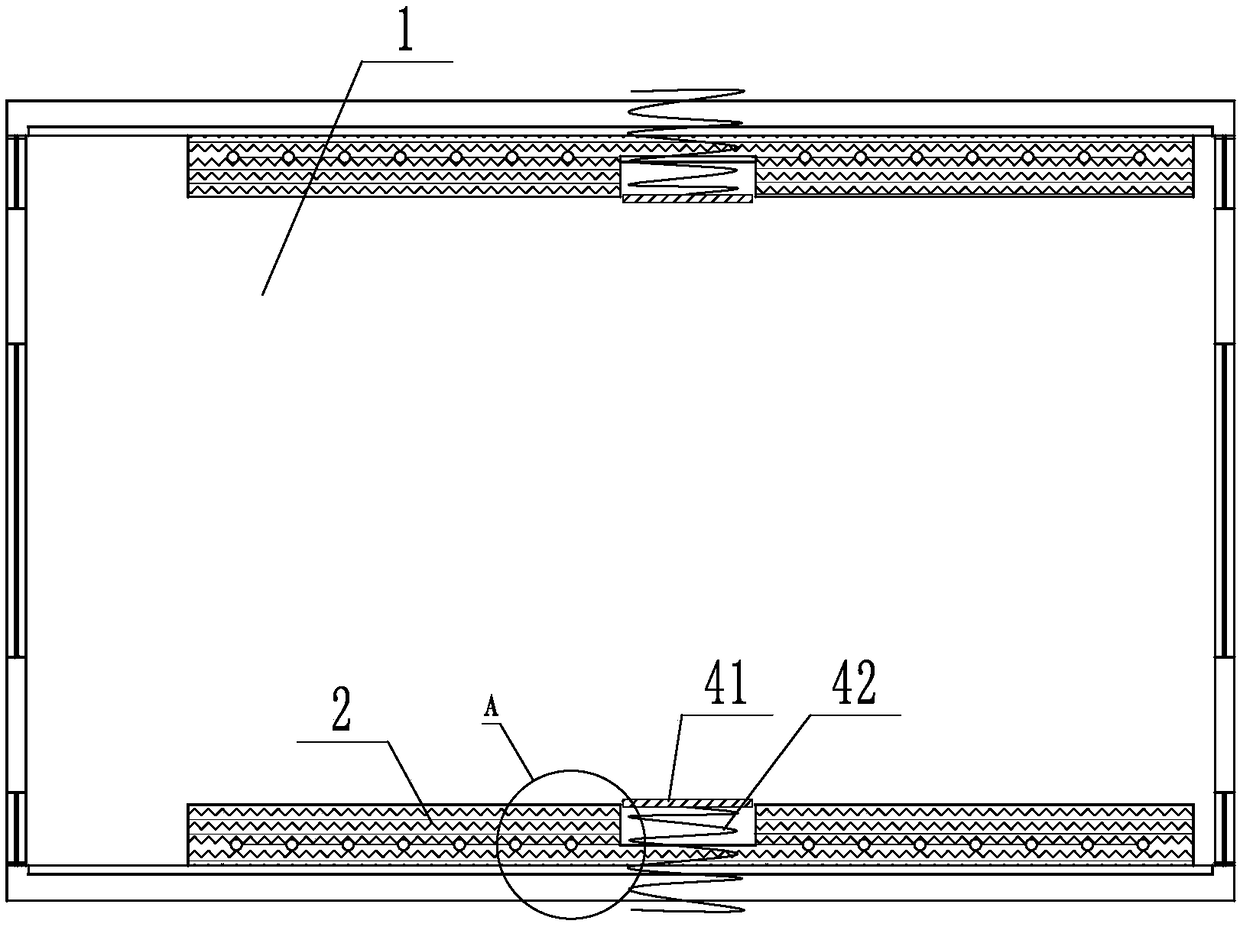

[0029] Such as Figure 1 to Figure 2 As shown, a server package paper tray includes a shell assembly 1 and a spacer 2. The shell assembly includes a bottom plate 11, a left side plate 12, a right side plate, a front side plate 13 and a rear side plate. The bottom plate 11 is connected with The left side panel 12, the right side panel, the front side panel 13 and the rear side panel, and the shell assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com