A lens upper and lower cartoning machine

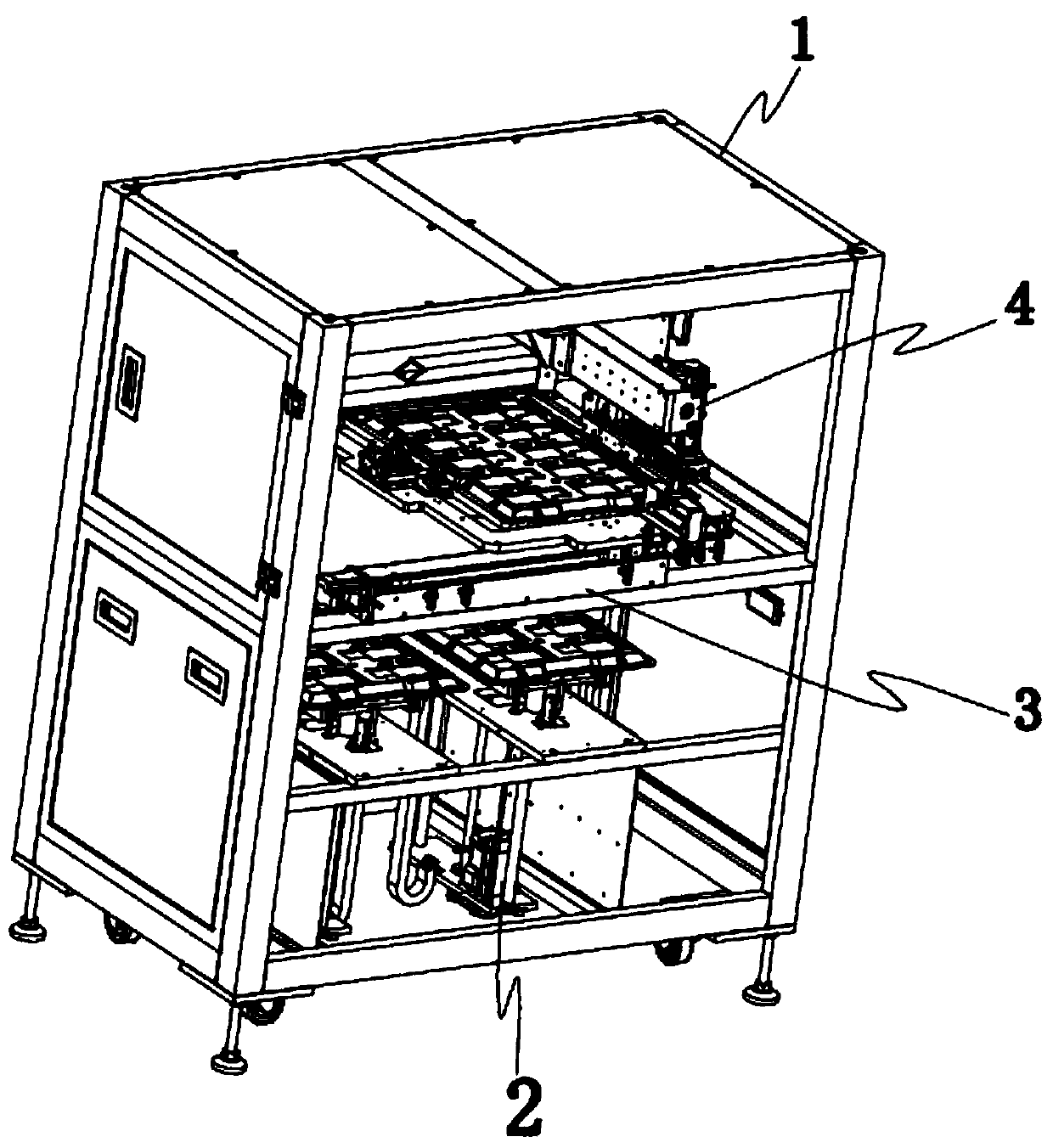

A cartoning machine and lens technology, applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems that the microscope lens affects the quality of the factory, dust and debris are easy to stick to the surface of the lens, and the observation effect of the microscope lens is poor. Prevent the mirror surface from being polluted by the operator, reduce labor cost input, and have good packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

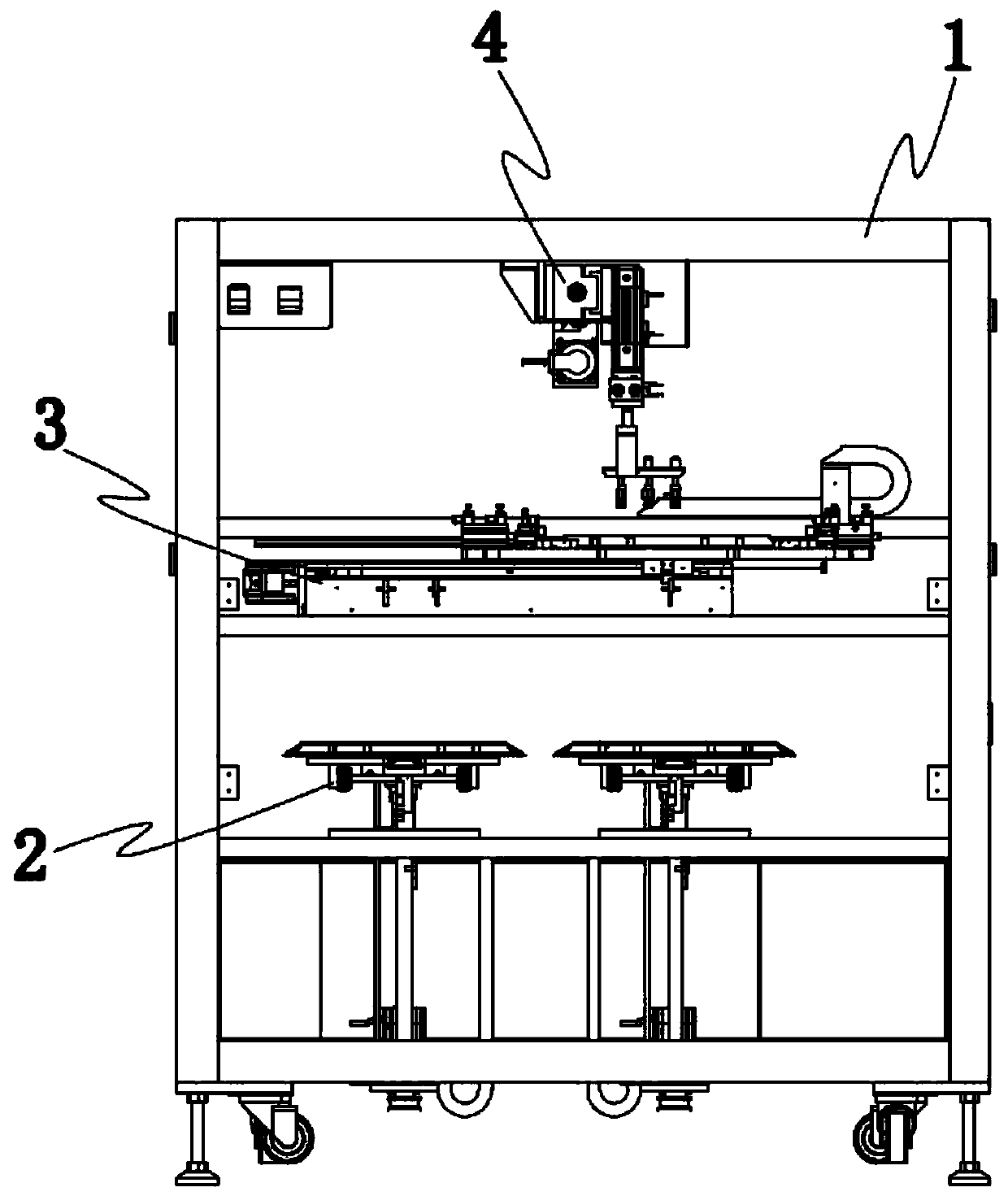

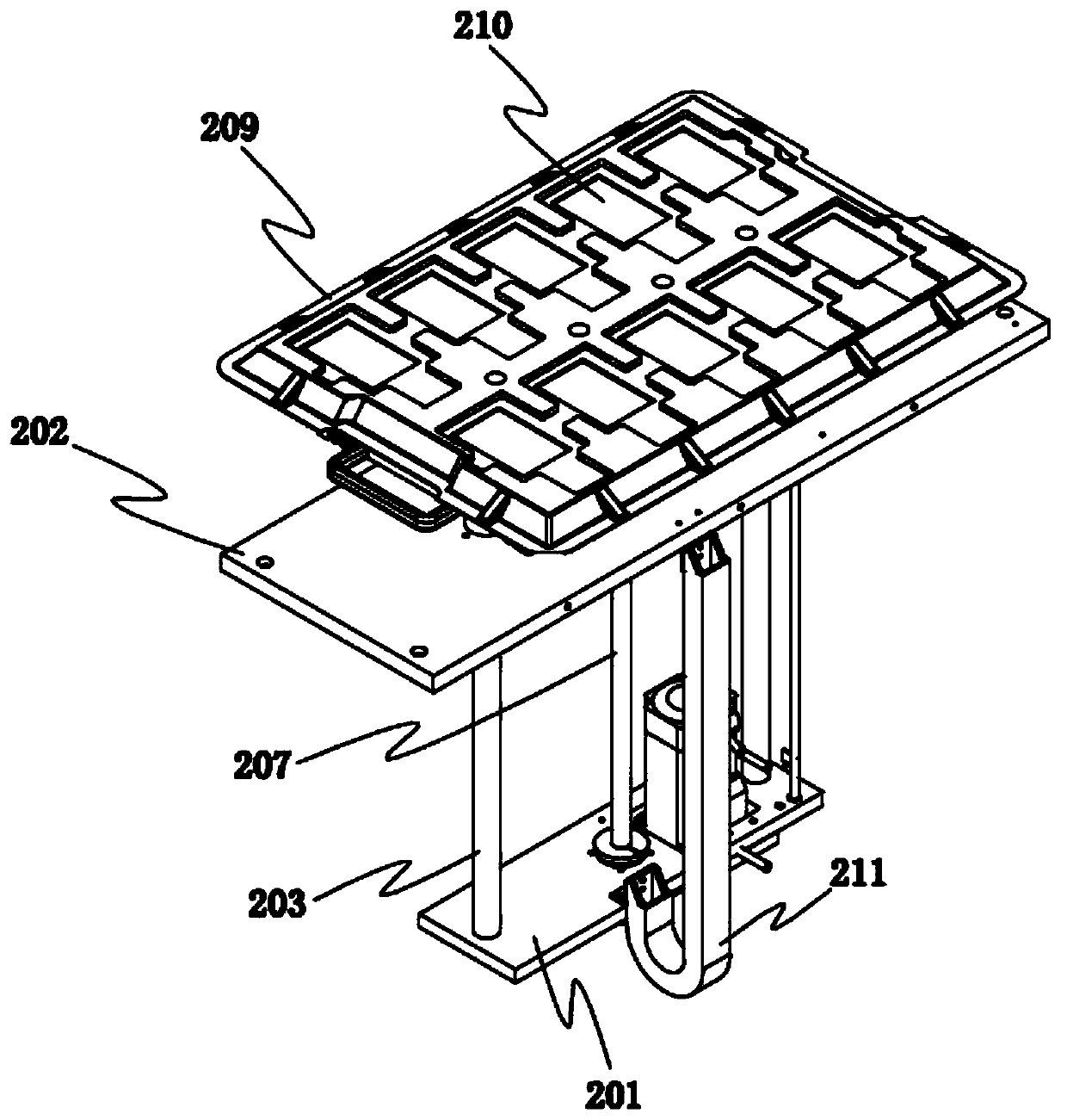

[0035] When the box body lifting mechanism 2 of this cartoning machine lifts the input packaging box 209, the packaging box 209 is placed on the fixed table 208 earlier, and the vertical drive motor 204 is started, and the vertical drive motor 204 drives the vertical drive through the belt transmission mechanism. The direct drive screw 207 rotates, and the rotating vertical drive screw 207 gradually lifts the fixed table 208 and the packaging box 209, and finally lifts the packaging box 209 to the center of the clamping frame 301 of the box clamping translation mechanism 3. In the frame fixing groove 302, when lifting the packaging box 209, only the vertical drive motor 204 of the box lifting mechanism 2 needs to be manually controlled, and the operation is simple and convenient.

Embodiment 2

[0037] When the box body clamping translation mechanism 3 of this cartoning machine clamps and translates the packaging box 209, by starting the clamping cylinder 303, the piston rod of the clamping cylinder 303 stretches out, so that the clamping bar 305 of the rod portion is in contact with the packaging box 209. Side clamping realizes the clamping of the packaging box 209, and at the same time when the lens is boxed, by starting the translation drive motor 307, the translation drive screw 310 is driven to rotate, so that the translation block 311 pulls and clamps the frame body 301 to translate along the Drive the screw rod 310 to translate in the length direction, thereby realizing clamping and translation of the packaging box 209 .

Embodiment 3

[0039] When the lens grabbing mechanism 4 of this cartoning machine grabs the lens, the front and rear drive motor 403 on the grab mounting frame 401 drives the up and down drive cylinder 407 and the front and rear moving block 406 drives the screw rod 408 to the lens on the outside of the cabinet body 1 along the front and rear. When the position moves, when reaching the designated position of the lens, then start the up and down drive cylinder 407, the piston rod of the up and down drive cylinder 407 drives the suction nozzle 409 to move down the suction lens, and the up and down drive cylinder 407 piston rod drives the suction nozzle 409 of the suction lens to move up, then back and forth The driving motor 403 drives the upper and lower driving cylinder 407 together with the lens to move to the top of the packaging box 209 along the front and rear driving screw rod 408, and then the upper and lower driving cylinder 407 moves down the suction nozzle 409, and the suction nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com