Heat bending and shaping glass and preparation process thereof

A preparation process and glass technology, applied in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve the problems of surface distortion, contact damage, reduce the mirror reflection ability of high-energy band solar radiation, achieve good shape, improve the concentration Good light effect and concentrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

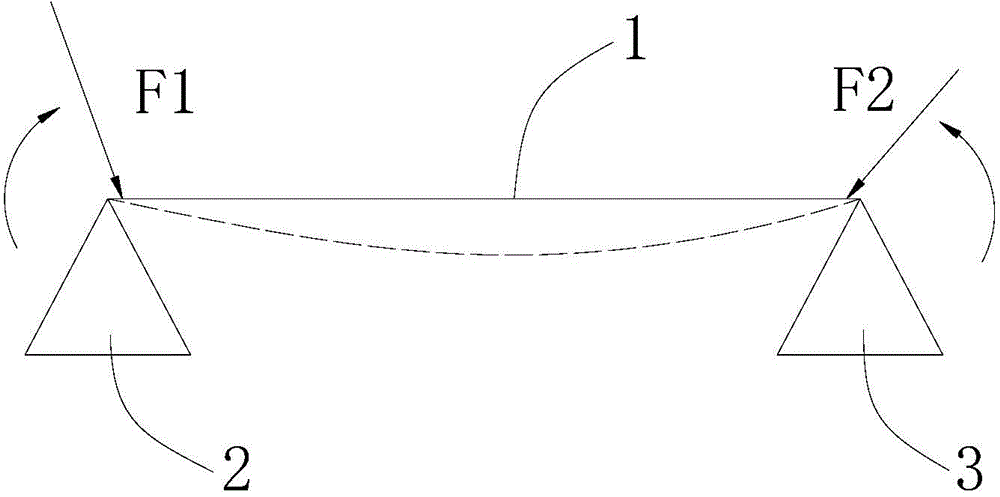

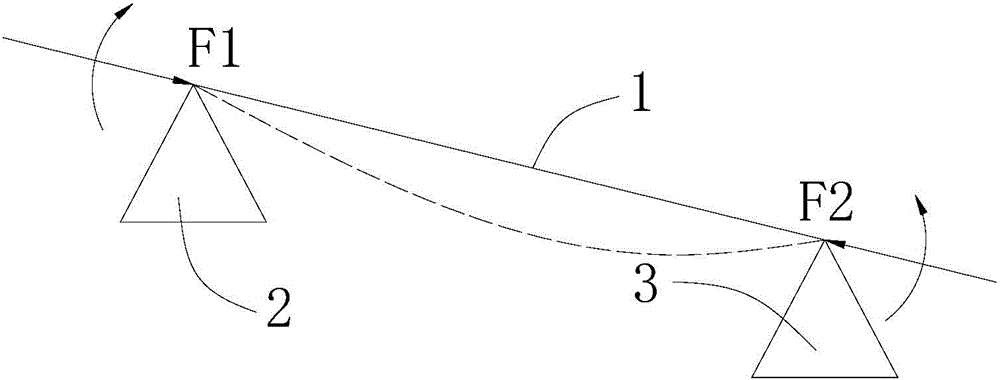

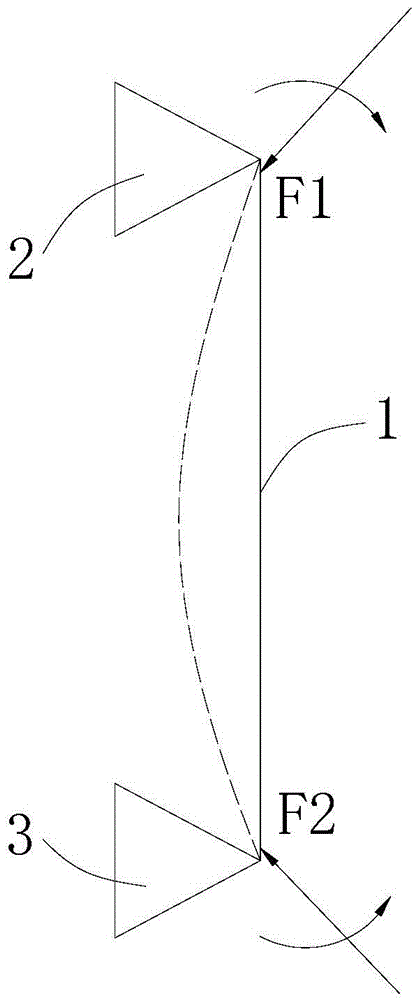

[0037] The above-mentioned preparation process of hot-bending shaped glass is used for hot-bending flat glass 1 to make a concentrating mirror for thermoelectric power generation. In this embodiment, the glass 1 is rectangular glass, and the preparation process includes the following steps:

[0038] (1) Place the opposite long sides of the rectangular glass on the first support 2 and the second support 3 respectively, the lengths of the first support 2 and the second support 3 are slightly longer than the long sides of the glass 1 The length of which is fixed on the base at its lower end. Between the first support 2 and the second support 3 there is a gap space for the glass 1 to be bent, softened and collapsed, the first support 2 and the second support 3 are adjusted so that they are distributed along the horizontal direction and Parallel and equal height settings.

[0039] (2) Apply a first force F1 to the first side of the glass 1 placed on the first support 2 to form a ...

Embodiment 4

[0052] Embodiment 4 is the hot-bending shaped glass prepared by the preparation process in Embodiment 1. The direction and magnitude of the first acting force F1 and the second acting force F2 make the height of the hot bending arch height formed by the first bending moment and the second bending moment on the glass 1 thermally bent and shaped to be related to the uniform load of the glass 1 itself. The height of the hot-bending arch formed by hot-bending forming is the same; at the same time, the heating temperature decreases evenly along the center line of the first side and the second side to both sides and is distributed symmetrically. The concentrating effect of the concentrating lens made of hot-bent glass is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com