Light emitting diodes and producing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of time-consuming work process, increased production cost expenditure, and limited light-gathering effect, achieving low manufacturing cost and simple manufacturing process , good light-gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

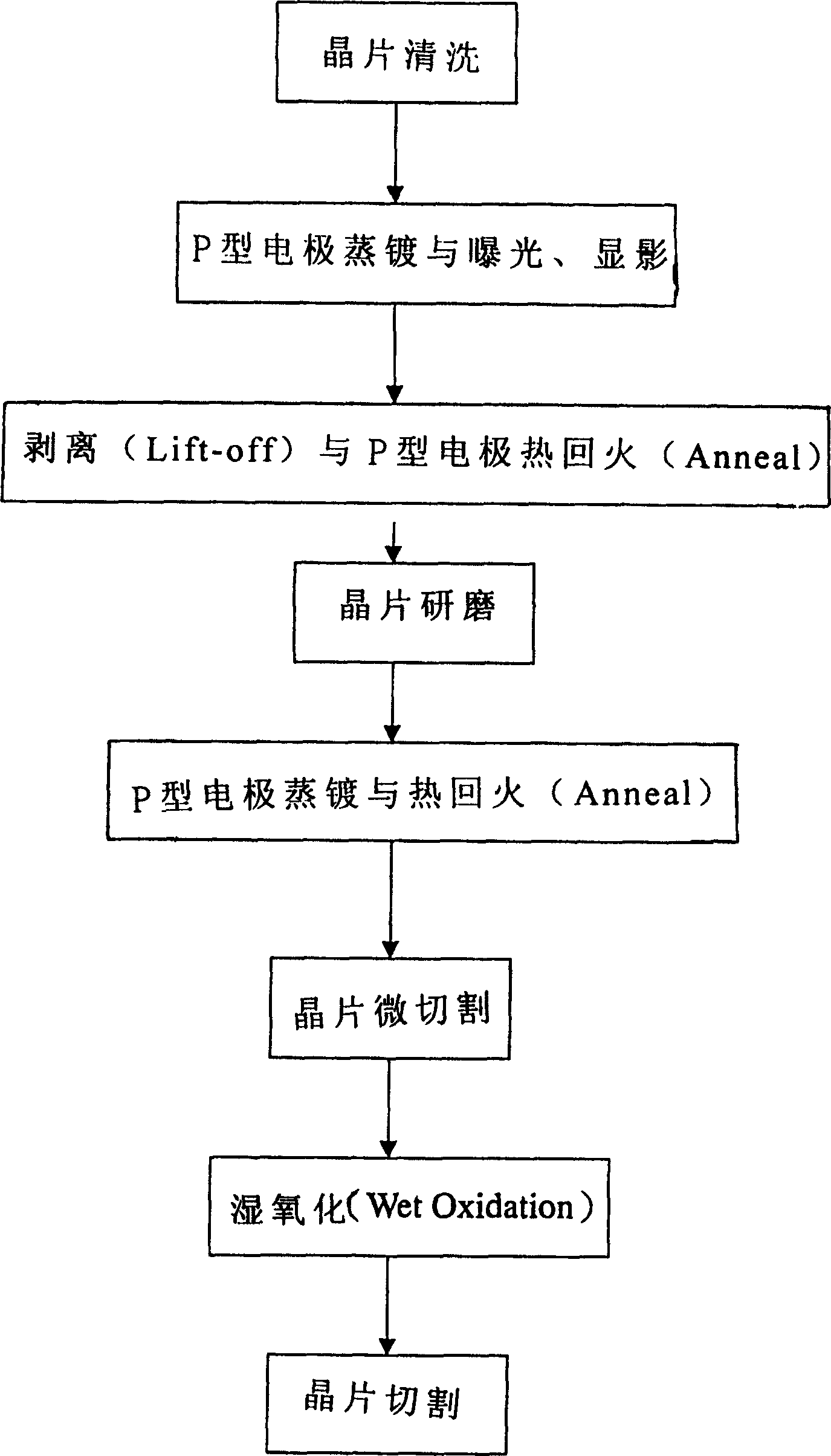

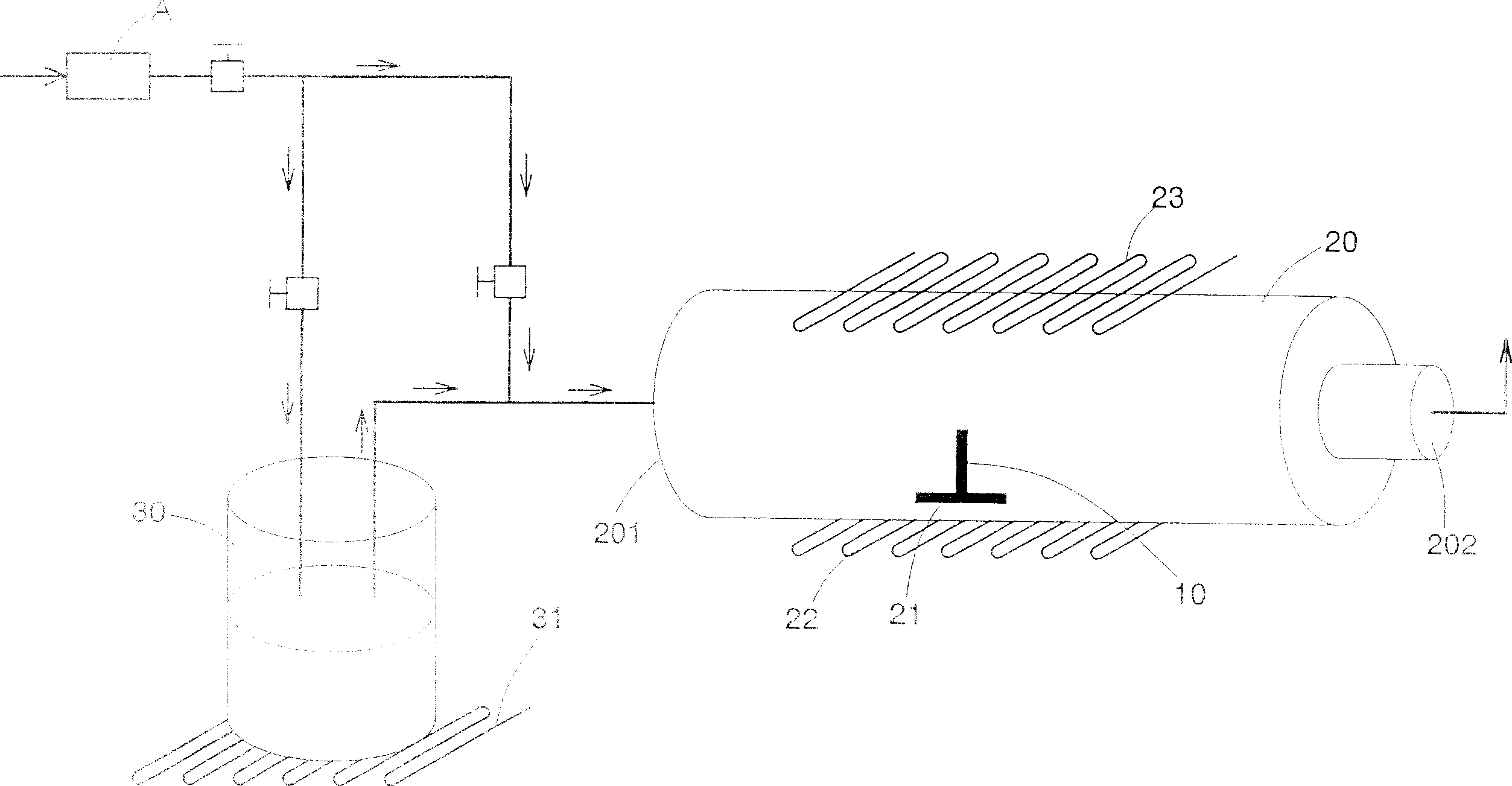

[0039] First, see figure 1 The block diagram of the wet oxidation process is shown, which firstly cleans the wafer subjected to wet oxidation treatment, then vapor-deposits the wafer with a P-type electrode (hereinafter referred to as the front electrode), and causes the front electrode to be exposed, developed, and peeled off from the front electrode. Thermal tempering, the wafer is ground, and the front electrode is evaporated and thermally tempered, and then the wafer is micro-cut. After the wet oxidation operation is applied to form an insulating layer that prevents the flow of current, the wafer is finally cut. .

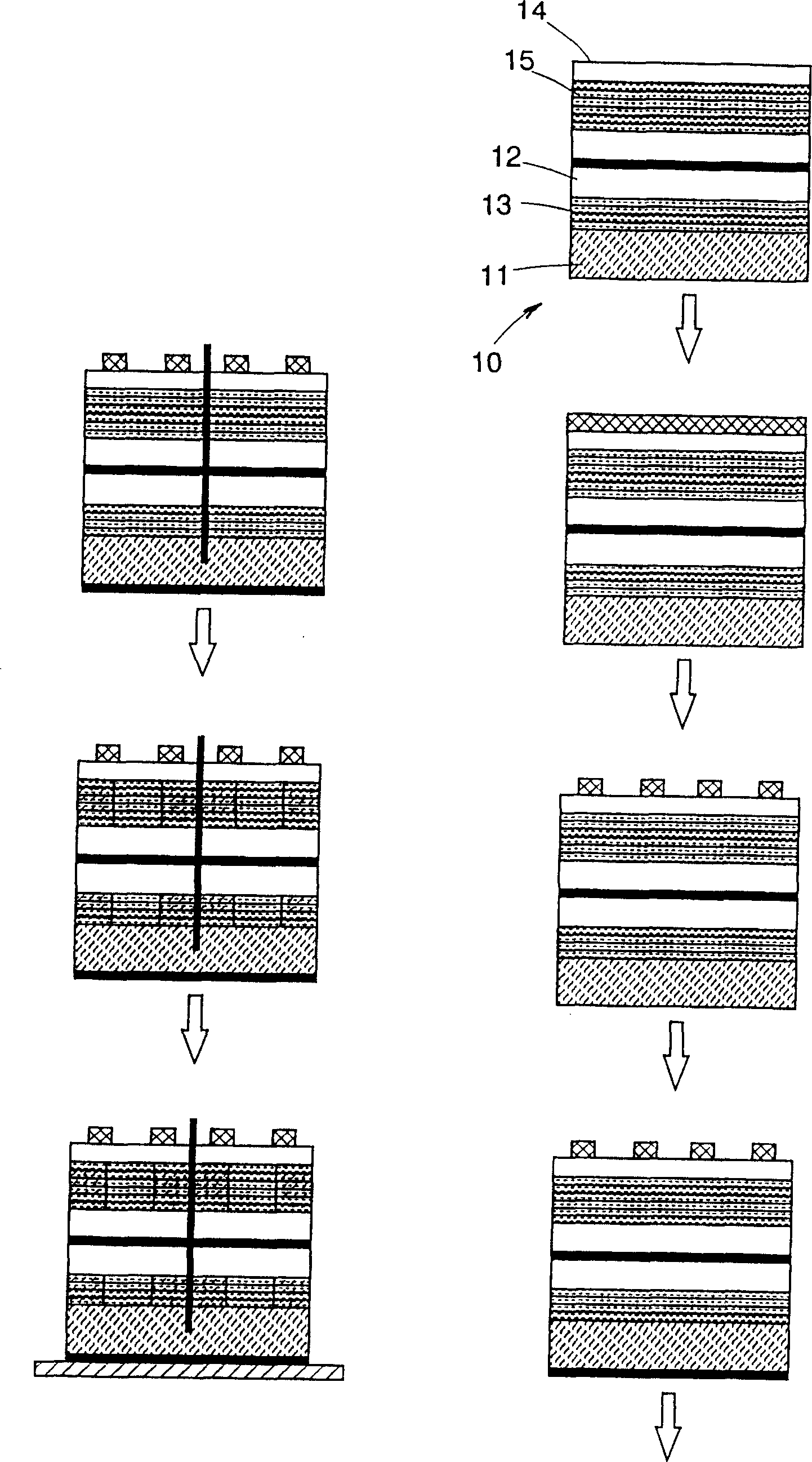

[0040] For the detailed wet oxidation process method, please refer to figure 2 Flow chart of the wet oxidation process shown. The manufacturing method of the light-emitting diode of the present invention mainly includes an active layer 12 on the base layer 11 of the epitaxial structure 10, a first Bragg reflection layer 13 between the active layer 12 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com