Silicon magnesium aluminum sol and doped core-shell silica microsphere coating solution and its preparation and application

A technology of hydroxy-silicon-magnesium-aluminum sol and magnesium-aluminum sol, which is applied in coating and other directions, can solve problems such as unsatisfactory performance, and achieve the effects of obvious power generation gain, high light transmittance, and reliable combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

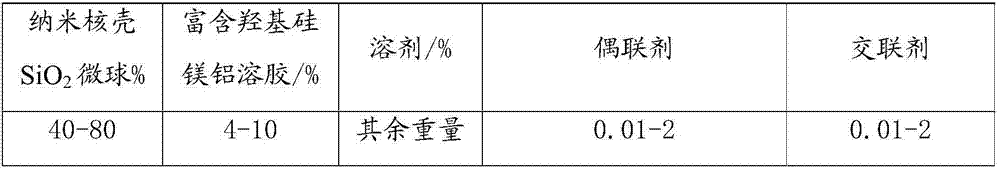

Method used

Image

Examples

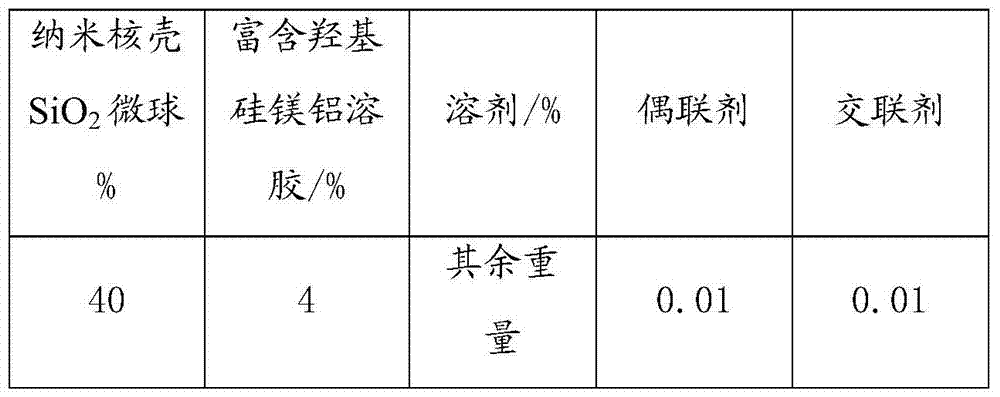

Embodiment 1

[0061] (1) Preparation of nano-core-shell SiO 2 microsphere sol

[0062] According to the literature "Monodisperse hollow SiO 2 Nano-core-shell core-shell SiO 2 Microsphere sol (Zou Hua, Wu Shishan, Shen Jian. Monodisperse hollow SiO 2 Synthesis and characterization of nano-microspheres. [J]. Acta Chem. 2009.67 (3) 266-269), the specific preparation process is as follows:

[0063] (1) Raw materials: Styrene (abbreviated as S), polyvinylpyrrolidone (abbreviated as PVP, K30) and ethyl orthosilicate (TEOS) were purchased from China Pharmaceutical Group Shanghai Chemical Reagent Company, and S was removed by 10wt% NaOH aqueous solution before polymerization Inhibitor, then carry out vacuum distillation (usually at -50KPa ~ -100KPa, in all embodiments of the present invention, carry out distillation at -80KPa), absolute ethanol and ammonia solution (25wt%) are produced in Nanjing Chemical Reagent Co., Ltd. Company, potassium persulfate (KPS) is produced by Tianjin Chemical Reag...

Embodiment 2

[0098] (1) Preparation of nano-core-shell SiO 2 microsphere sol

[0099] Prepare nano-core-shell SiO according to the same method as in Example 1 2 microsphere sol.

[0100] (2) Preparation method rich in hydroxyl silica sol

[0101] (1) Add 100ml of solvent isopropanol into the three-necked flask, and under the condition of stirring at 15°C, slowly add additional deionized water (here is additionally added deionized water) and catalyst nitric acid into the three-necked flask, and continue to stir 30min to obtain liquid A;

[0102] (2) Under the condition of stirring at 15°C, add aluminum salt aluminum chloride, magnesium salt magnesium acetate and tetraethoxysilane as an alkoxysilane into liquid A respectively, raise the temperature to 60°C and continue stirring for 2 hours, then stop stirring, Aged at 40° C. for 4 days, and cooled to obtain a hydroxyl-rich silica sol with a solid content of 10% by weight.

[0103] In the above process of preparing hydroxyl-rich silica s...

Embodiment 3

[0123] (1) Preparation of nano-core-shell SiO2 microsphere sol

[0124] Prepare nano-core-shell SiO according to the same method as in Example 1 2 microsphere sol.

[0125] (2) Preparation method rich in hydroxyl silica sol

[0126] (1) Add 100ml of solvent methanol into the three-necked flask, under the condition of stirring at 30°C, slowly add the uniformly mixed deionized water and catalyst nitric acid into the three-necked flask, and continue stirring for 30min to obtain liquid A;

[0127] (2) Under the condition of stirring at 30°C, add aluminum salt aluminum formate, magnesium salt magnesium acetylacetonate and tetraethoxysilane as alkoxysilane into liquid A respectively, raise the temperature to 60°C and continue stirring for 3 hours, then stop stirring, Aged at 60° C. for 4 days, and cooled to obtain a hydroxyl-rich silica sol with a solid content of 12% by weight.

[0128] The volume (or mass) ratio of solvent, deionized water, catalyst, magnesium salt, aluminum sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com