Method for forming annular halo

A ring-shaped, optical groove technology, applied in the field of lenses, can solve the problems of obvious light spots, uneven light distribution, clear boundaries, etc., and achieve the effect of increasing the number of reflections, improving the utilization rate, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

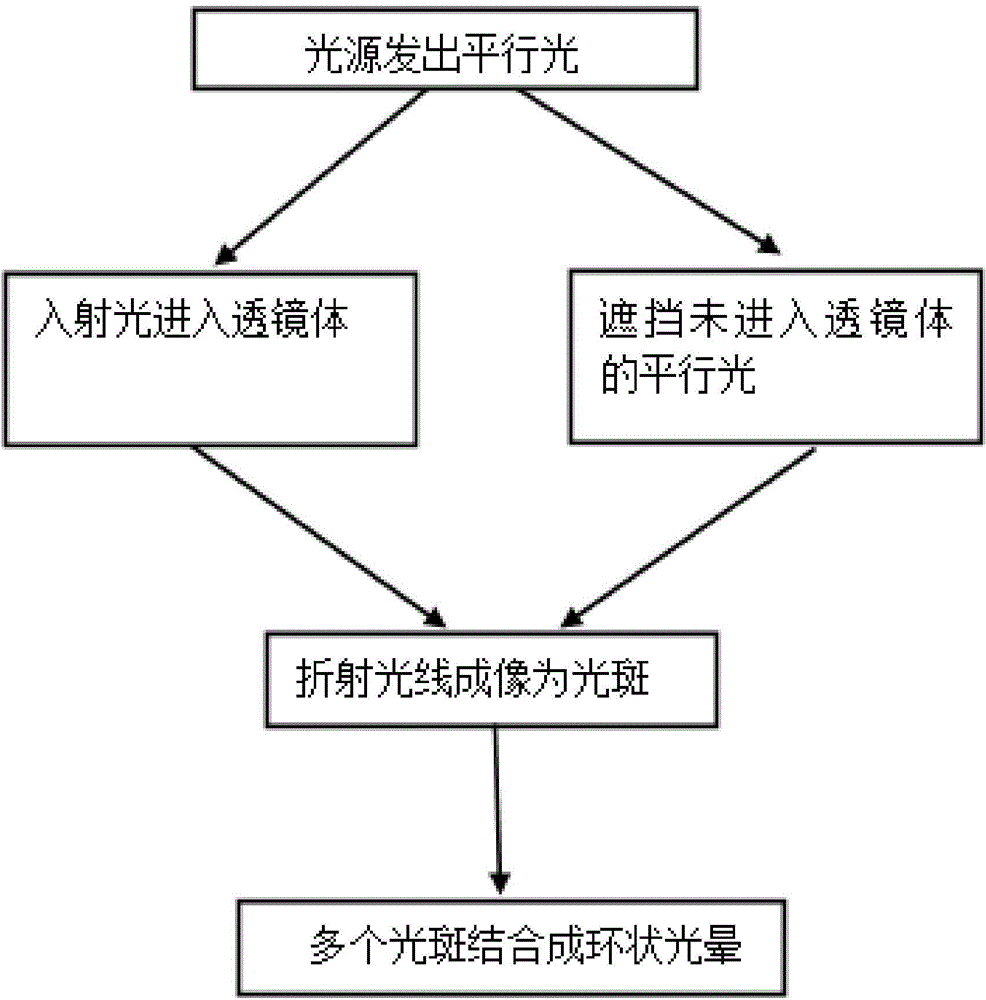

[0036] Such as Figure 1~5 Shown, a kind of method for forming annular halo, comprises the steps:

[0037] (a) The light source emits parallel light;

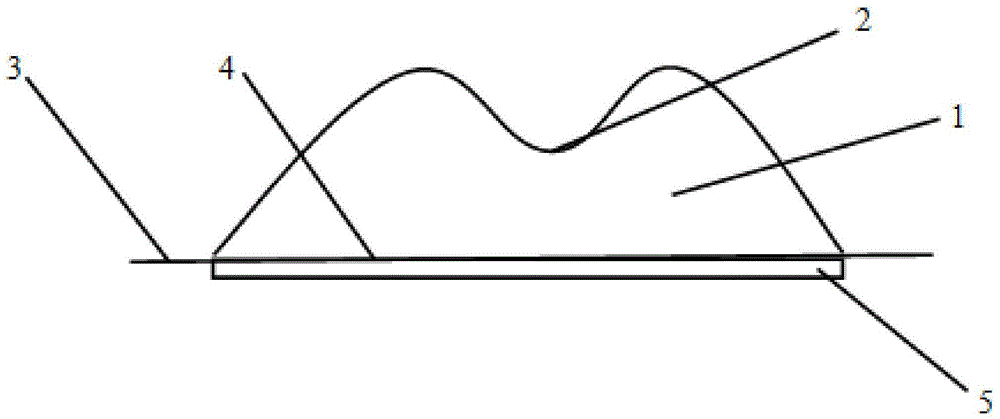

[0038] (b) Parallel light enters the lens body 1 with the light guide groove 5 at the bottom, and the lens body 1 has a concave structure in the middle and has a concave low point 2;

[0039] (c) When the parallel light enters the lens body 1, the parallel light that does not enter the lens body 1 is blocked;

[0040] (d) using a screen or similar device to image the refracted light refracted by the lens body 1;

[0041] (e) At the same time, on the same geometric plane, repeat the above steps (a) to (d) in the manner of uniform distribution on the concentric circle to form a plurality of light spots refracted by the lens body 1, and the multiple light spots are finally Form a ring halo.

[0042] In the method for forming an annular halo in this embodiment, the number of repetitions of the step (e) is 12 times. The cross s...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 lies in that the cross section of the lens body 1 in the step (b) described in this embodiment is circular. There are 2 concentric circles in the step (e); repeat step (e) 12 times on each concentric circle. The ratio of the distance from the concave low point 2 to the lens bottom surface 4 in step (b) of this embodiment to the distance from the highest point of the lens body 1 to the lens bottom surface 4 is 1:5.

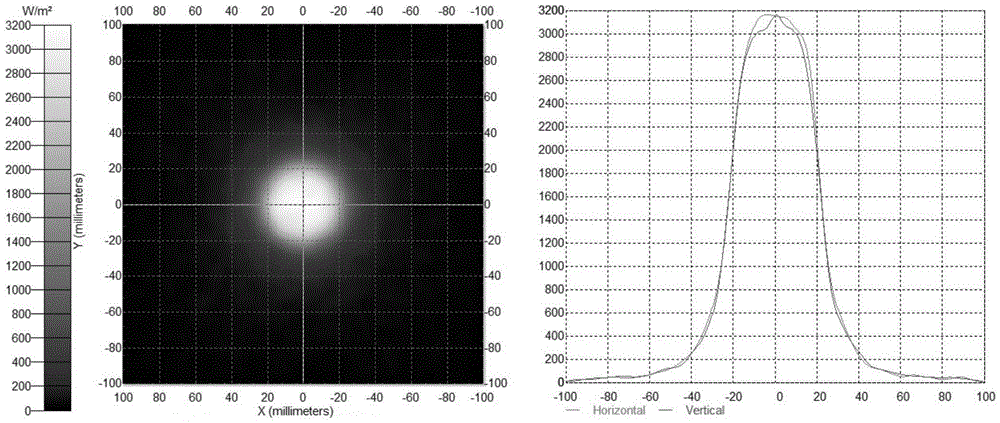

[0047] During the implementation of this embodiment, the parallel light emitted by the light source enters through the light guide groove 5, such as figure 2 The shown lens body 1 becomes as follows under the refraction of a single lens body 1 image 3 The spots shown. From image 3 It can be seen that the distribution of a single spot is formed by the superposition of two beams of light. The two beams of light complement each other to avoid uneven brightness and darkness in the center. The outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com