High-lift system whole-aircraft loading dynamic test method

A dynamic test and loading actuation technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as inaccurate design test results of high-lift systems, and solve major aircraft failures, Changing the effects of serious deficiencies and defects

Active Publication Date: 2015-09-23

XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a dynamic test method for full-machine loading of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

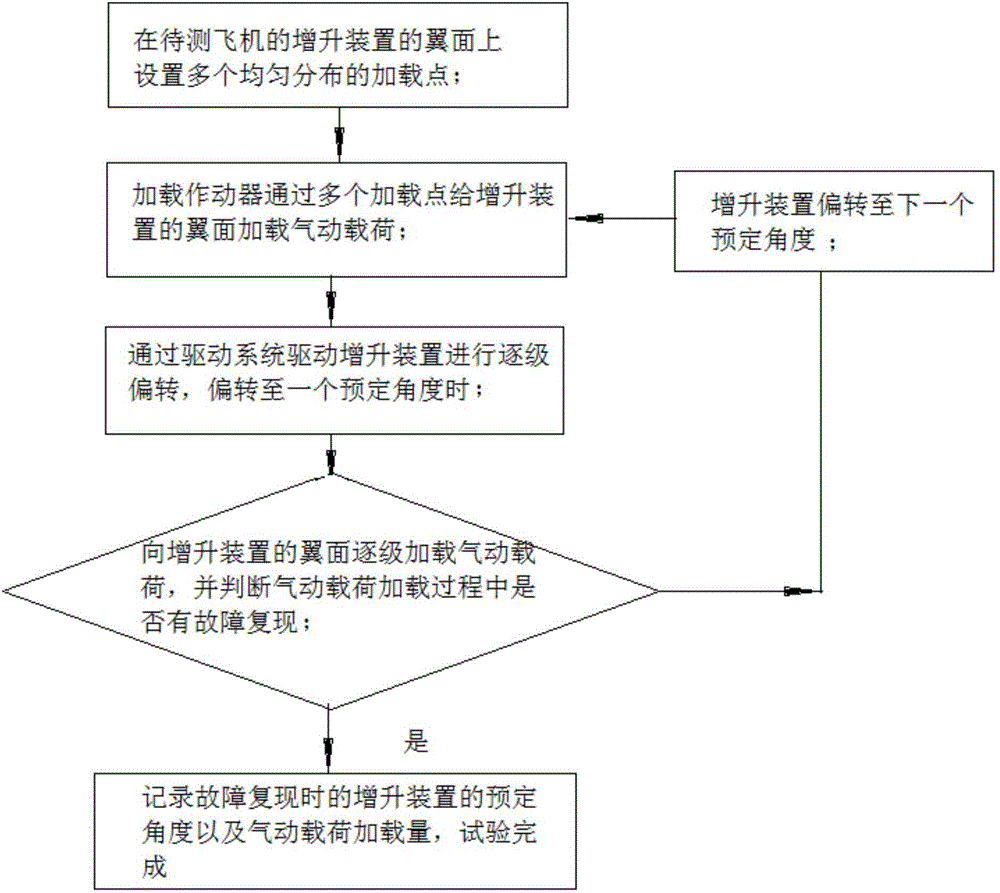

The invention relates to the field of aircraft high-lift system tests, in particular to a high-lift system whole-aircraft loading dynamic test method, so as to solve the problem that test results of the high-lift system design at present are incorrect. The high-lift system whole-aircraft loading dynamic test method loads an aerodynamic load on aerofoils of a high-lift device under the condition of a predetermined angle step by step through a loading actuator, judges whether a fault recurs during the process of loading the aerodynamic load to a limit load step by step under the predetermined angle so as to obtain magnitude of the loading load when the aircraft fails, can truly simulate the real flying condition of the aircraft high-lift system, confirms that the stress conditions of the high-lift system, the relevant high-lift device, wing boxes and the like in whole-aircraft tests are consistent to that of the same in the air, and eliminates major flight failures of the aircraft; in addition, the high-lift system whole-aircraft loading dynamic test method is a breakthrough of the dynamic driving/coordinated loading technology, and changes the severe shortages and deficiencies of the previous test methods essentially.

Description

technical field [0001] The invention relates to the field of aircraft high-lift system testing, in particular to a dynamic test method for full-aircraft loading of the high-lift system. Background technique [0002] In the past high-lift system tests, due to the limitations of design ideas, the motion function inspection test of the high-lift system was only loaded on the wing box and the fuselage without loading the high-lift device; at this time, the high-lift system driving the high-lift device was basically at The unloaded conditions are completely different and unreal from the actual flight conditions. Such a test cannot test the influence of the design and manufacturing process of the aircraft's high-lift system, and there are great hidden dangers in the aircraft flight test. Since the follow-up loading system of the full-stroke increasing lift device is very expensive, it has not been used in previous aircraft static tests. Thus, for newly developed aircraft, there ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/00

Inventor 左朋杰张建刚

Owner XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com