A method for manufacturing a circular test mold for testing mortar and concrete shrinkage cracking

A technology of shrinkage cracking and manufacturing methods, which is applied in the field of building materials engineering, can solve the problems of unreasonable design of the ring test mold, long test time of the ring method, and limitation of the application of the ring method, etc., so as to achieve a short time for removing the test piece , good design concept, quick disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

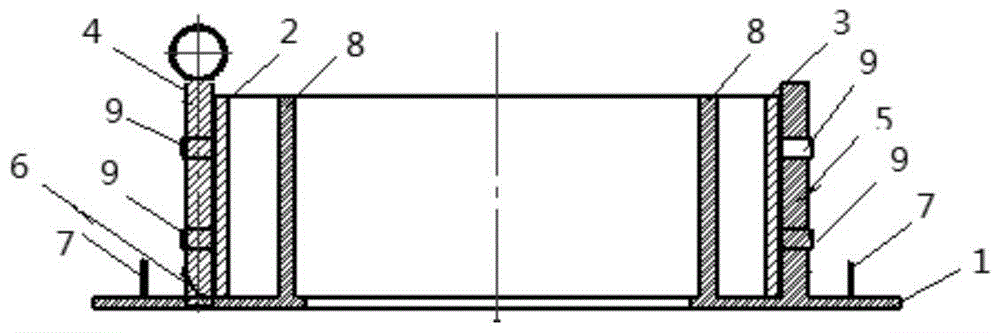

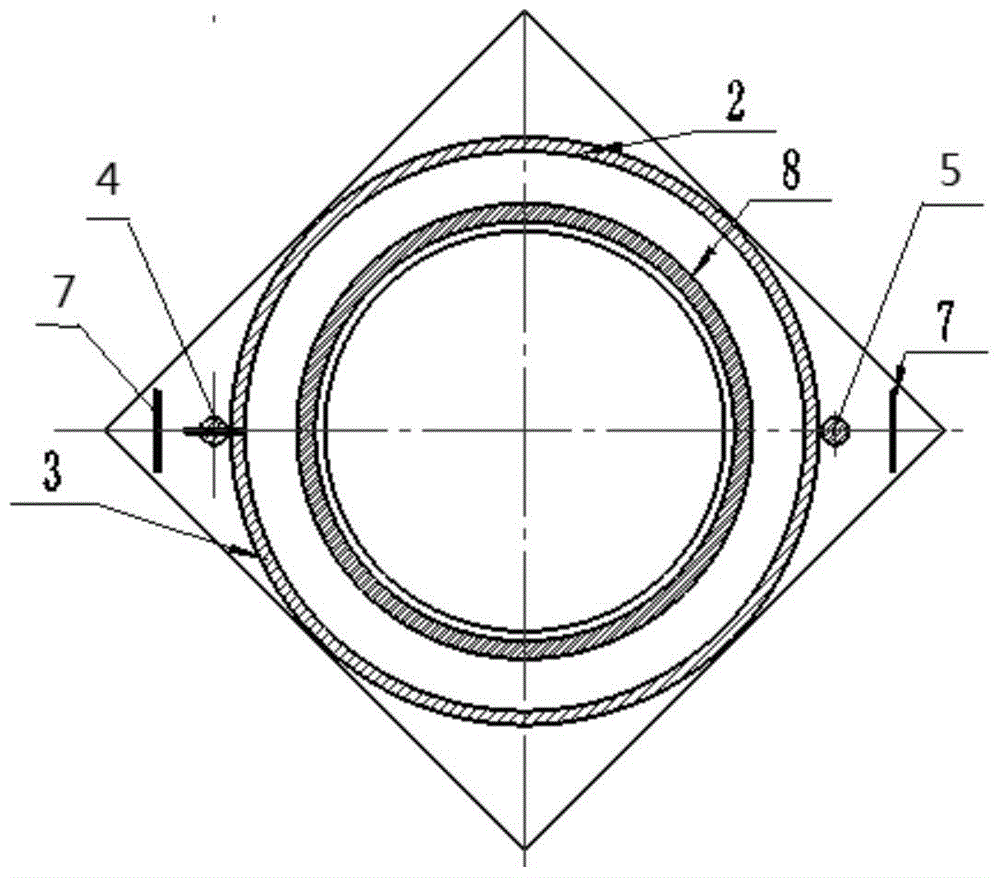

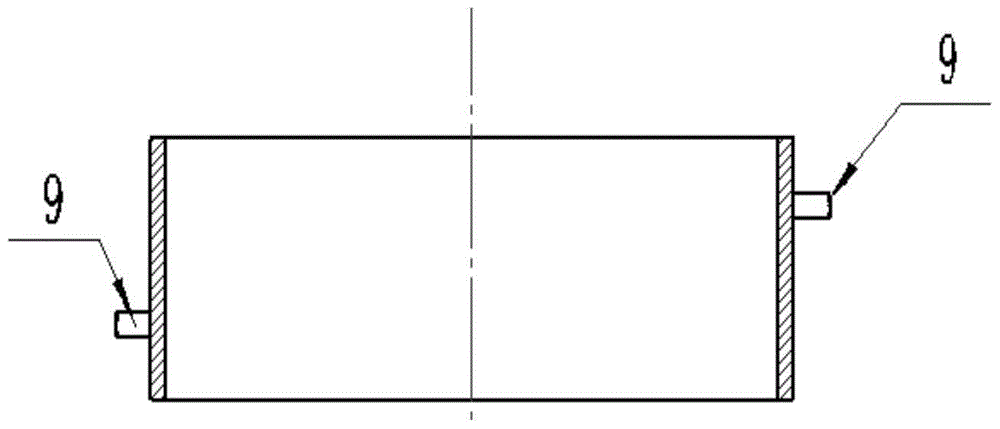

[0025] Such as Figure 1-8 shown.

[0026] (1) Making the hollow ring base 1: The hollow ring base 1 is composed of five parts: a hollow base plate, an inner ring 8, a fixing column 5, a fixing groove 6 and a handle 7, all of which are made of Q235 steel; wherein, the hollow base plate is square, Thickness 6mm, length 430mm, cut off a circle with a diameter of 290mm at the geometric center of the square hollow ring base 1, deburr and chamfer after cutting; inner ring 8 inner diameter 302mm, thickness 8mm, height 155mm, inner ring 8 and hollow ring base 1 The geometric centers coincide and are fixed on the hollow floor by welding; the fixed column 5 has a diameter of 18mm and a height of 165mm, and the fixed column 5 is located at a distance of 224mm from the center on the diagonal of the square floor, and is fixed on the hollow floor by welding; the fixed groove 6. The notch has a diameter of 20 mm and a depth of 4 mm, and is symmetrically distributed with the fixed column 5....

Embodiment 2

[0031] (1) Making the hollow ring base 1: The hollow ring base 1 is composed of five parts: a hollow base plate, an inner ring 8, a fixing column 5, a fixing groove 6 and a handle 7, all of which are made of Q235 steel; wherein, the hollow base plate is square, Thickness 6mm, length 432mm, cut off a circle with a diameter of 292mm at the geometric center of the square hollow ring base 1, deburr and chamfer after cutting; inner ring 8 inner diameter 302mm, thickness 10mm, height 165mm, inner ring 8 and hollow ring base 1 The geometric centers coincide and are fixed on the hollow floor by welding; the fixed column 5 has a diameter of 18mm and a height of 167mm, and the fixed column 5 is located at a distance of 224mm from the center on the diagonal of the square floor, and is fixed on the hollow floor by welding; the fixed groove 6 The notch has a diameter of 20 mm and a depth of 5 mm, and is symmetrically distributed with the fixed column 5. It is located at 224 mm in the opposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com