A device for detecting road surface damage caused by twisting action and its measuring method

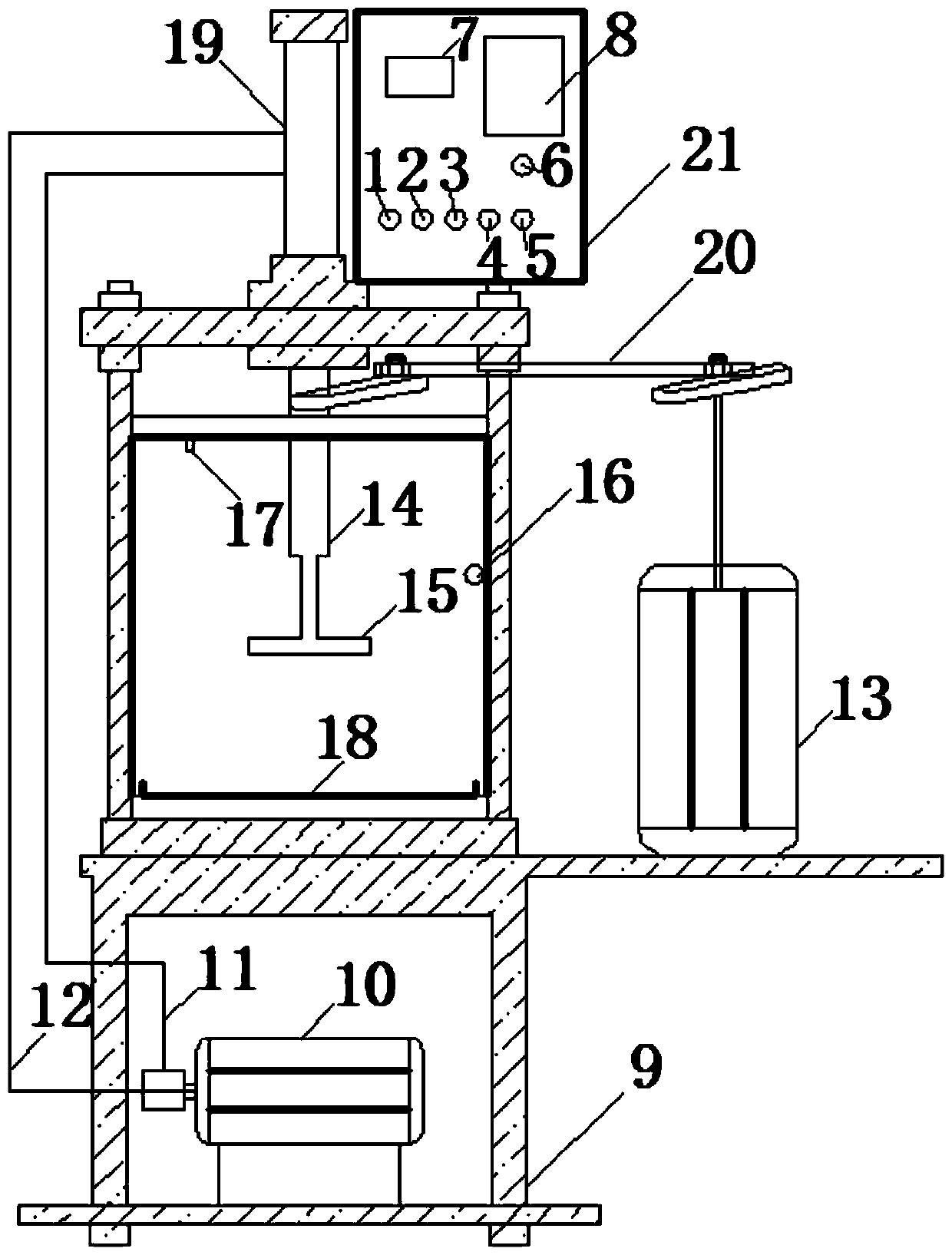

A function and hydraulic device technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of no test method and detection index, and solve the problems that cannot be delayed, so as to facilitate the picking and placing of parts and test observation and test The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

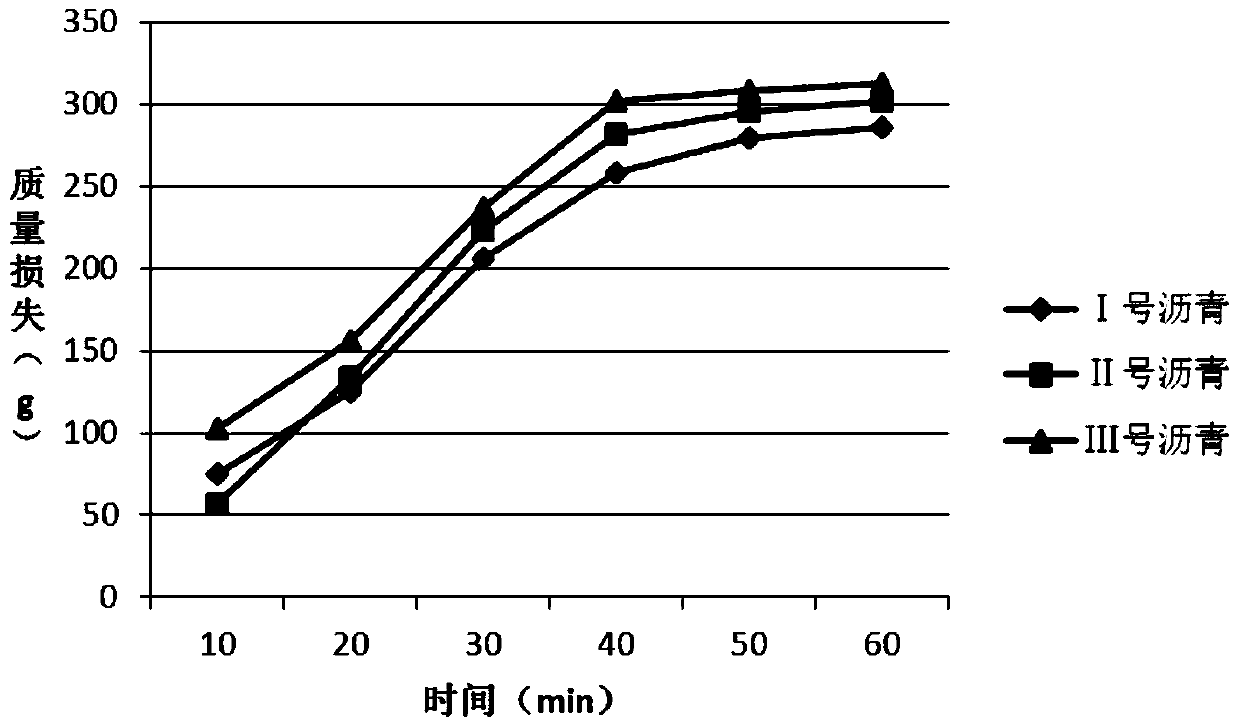

[0056] Three different No. 90 ordinary asphalt mixtures are graded and mixed according to OGFC-13. Among them, No. 1 is Karamay No. 90, No. 2 is Donghai No. 90, and No. 3 is Zhonghai No. 90, and rutting plates are made according to the test specifications. Several test pieces were placed at room temperature to cool for 12 hours and then released from the mold for later use. Adopt the device of the present invention to carry out the test, set the pressure as 0.7MPa, and the temperature as 20°C, respectively take and record the loss mass of the rut slabs made of three kinds of asphalt at 10min, 20min, 30min, 40min, 50min and 60min, and the result Table 1 and image 3 shown.

[0057] Table 1 OGFC-13 mixture mass loss

[0058]

[0059] From Table 1 and image 3 It can be seen that the asphalt pavement of OGFC-13 asphalt mixture has a tendency to gradually adapt to the "twisting" effect with the increase of the action time at 0.7MPa and 20°C, the action surface will become sm...

Embodiment 2

[0061] Three different No. 90 ordinary asphalt mixtures were mixed according to AC-13 grades, among which No. 1 was Karamay No. 90, No. 2 was Donghai No. 90, and No. 3 was Zhonghai No. 90. Rutting plates were made according to the test specifications Several test pieces were placed at room temperature to cool for 12 hours and then released from the mold for later use.

[0062] Utilize the device of the present invention to carry out the test, set the pressure as 0.7MPa, and the temperature as 60°C. Weigh and record the mass loss of the rutting slabs made of three different asphalts at 10min, 20min, 30min, and 40min respectively. The results are shown in Table 2 and Figure 4 shown.

[0063] Table 2 AC-13 mixture mass loss

[0064]

[0065] From Table 2 and Figure 4 It can be seen that the growth rate of AC-13 asphalt mixture at 0.7MPa and 60°C increases with the increase of action time, and the loss of "twisting" action eventually slows down, and as the loss increases to...

Embodiment 3

[0067] From examples 1 and 2, we know that Karamay No. 90 asphalt has the best performance in the test, and its loose loss is the smallest. We use Karamay No. 90 asphalt to configure three kinds of asphalt mixtures: AC-13, OGFC-13 and SMA-13. Make rut plate specimens by rolling method (no less than 12 specimens for one gradation, no less than 4 specimens for each group, do parallel test) for standby, set time for 40min, temperature at 40°C, under pressure See Table 3 and Figure 5 :

[0068] Table 3 Loose loss mass of different types of asphalt mixtures under different pressures

[0069]

[0070] From Table 3 and Figure 5 It can be seen that in the "twisting" action, the tire exerts a torque on the asphalt pavement through friction, so the magnitude of the pressure is directly related to the magnitude of the "twisting" force. Through the above analysis of the influence of the pressure on the test results, the pressure can be obtained Small, the "twisting" force is insuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com